Table of Contents

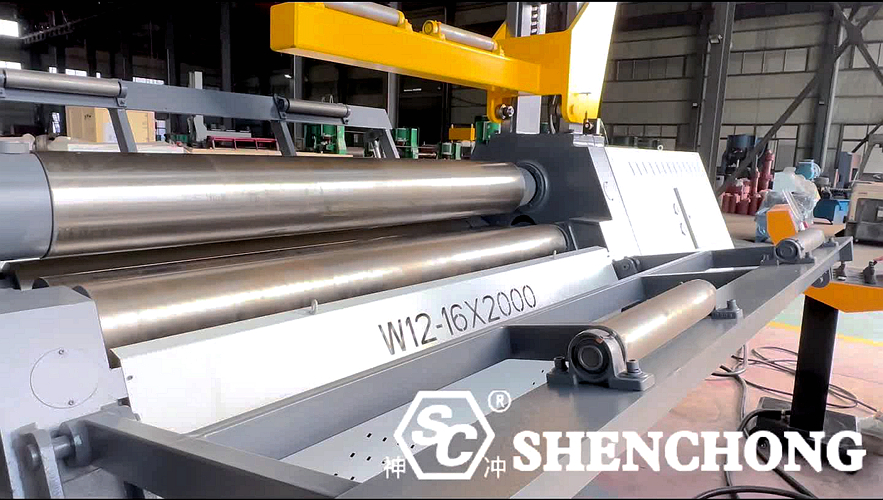

SC four roller plate bending machine is a rolling machine capable of rolling plates with a maximum thickness of approximately 16 mm and a maximum effective rolling width of 2000 mm. This SC W12 16X2000mm 4-roll plate bending machine to Armenia is a professional plate rolling equipment suitable for medium and heavy plates, offering high precision, high efficiency, and automation and mass production. It is mainly used to roll flat metals (such as steel plates, stainless steel plates, etc.) into cylinders, arcs, or other complex shapes.

1. Structure & Core Components Of 16X2000mm 4-Roll Plate Bending Machine

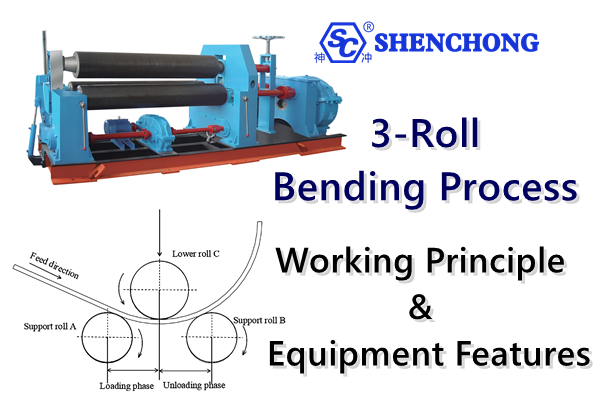

A four-roll plate rolling machine consists of four rollers:

- Top Roller: Typically the main drive roller, responsible for propelling the plate forward.

- Bottom Roller: Can be raised or lowered, serving for clamping and bending.

- Side Rollers: Located on the left and right sides, used to assist in bending and pre-bending the edges.

Compared to three-roll machines, four-roll machines offer superior plate force control and automation, resulting in more precise rolling and shorter straight edge sections.

2. Working Principle of Four-Roller Plate Rolling Machine

- Placing the Plate: The metal plate is placed between the machine’s rollers.

- Clamping and Pre-Bending: The lower and side rollers rise to clamp the plate, while the upper roller rotates to move the plate. Simultaneously, the side rollers pre-bend the edges of the plate, improving rolling accuracy.

- Rolling and Forming: The control system (hydraulic or CNC) drives the rollers to gradually apply pressure according to a set program, bending the plate into a circle or other geometric shape.

- Discharge and Correction: After rolling, the product is disassembled or adjusted. Subsequent processing, such as welding, may be performed if necessary.

The four-roll design allows pre-bending and main bending to be completed in a single pass, reducing repetitive operations and improving efficiency.

3. Typical Technical Parameters

Parameter Table for 16X2000MM 4-Roll Plate Bending Machine:

Parameters | Typical values (W12CNC-16X2000) |

Maximum winding thickness | 16 mm (carbon steel) |

Maximum pre-bending thickness | Carbon steel 12 mm, stainless steel 8 mm |

Maximum effective width | 2000 mm |

Upper roll diameter | Approx. 280-300 mm |

Lower roll diameter | Approx. 260-280 mm |

Side roll diameter | Approx. 220-240 mm |

Minimum winding diameter | Approx. 1.2-1.5 × upper roller diameter |

Winding speed | 3-5 m/min |

Main motor power | Approx. 15–22 kW |

Control method | NC / CNC (optional) |

4. Key Advantages And Features Of SC Four-Roller Bending Machine

This SC 16X2000mm 4-roll plate bending machine to Armenia is specifically designed for high-precision rolling of medium and heavy plates. It integrates mature hydraulic technology with a stable CNC control system, achieving one-time clamping, automatic pre-bending, and precise rounding of the plate.

Compared to the traditional three-roll bending machine structure, four-roll rolling offers superior performance in straight edge control, roundness consistency, and production efficiency, making it an ideal choice for modern sheet metal and cylinder manufacturing enterprises.

Four-roll structure • Strong pre-bending capacity

Independent hydraulic control of the upper, lower, and side rolls ensures automatic plate centering, short straight edges at the ends, and stable forming quality.

High-rigidity frame • Durable and stable

The integral welded frame undergoes stress relief treatment, ensuring no deformation under long-term high-load operation and suitable for continuous production.

- CNC system • Smarter operation

Supports NC/CNC control, real-time roller position feedback, intuitive parameter settings, and high repeatability.

- Automation adaptability • Strong expandability

Can be integrated into automatic loading and unloading, side-tilting unloading, and rolling production lines to meet the needs of large-scale manufacturing.

5. Application Areas

SC W12 16X2000 4-roller plate rolling machine is widely used in the following industries:

- Boiler manufacturing, pressure vessel manufacturing

- Petrochemical equipment

- Shipbuilding and marine engineering

- Steel structures such as bridges and towers

- Metal processing and manufacturing

Its main applications are the production of cylindrical, box-shaped, curved, and pipe fittings and other metal components.

Shenchong W12 16X2000mm 4-roll plate bending machine is widely used in pressure vessel, boiler manufacturing, petrochemical, environmental protection equipment, and steel structure engineering fields. It can efficiently roll cylindrical, curved, and multi-radius workpieces. With its high precision, high efficiency, and high reliability, it helps companies increase production capacity, reduce reliance on manual labor, and create a stable and replicable rolling process.