Fiber laser generator adopted in the fiber laser cutting machine is a new type of fiber laser that is newly developed internationally. It outputs a high energy density laser beam and gathers it on the surface of the workpiece, causing the area illuminated by the ultra-fine focal spot on the workpiece to instantly melt and vaporize. The automatic cutting is achieved by moving the spot illumination position through the CNC mechanical system.

The fiber laser cutting machine can perform both flat sheet plate cutting and tube cutting, with neat and smooth edges, suitable for high-precision cutting of metal sheets or pipes.

Compared to ordinary CO2 laser cutting machines, it saves more space and gas consumption, has a high photoelectric conversion rate, and has different laser powers (1000W to 50000W), which can cut metals of different thicknesses. Fiber laser cutting machine is your good partner in completing the metal cutting process.

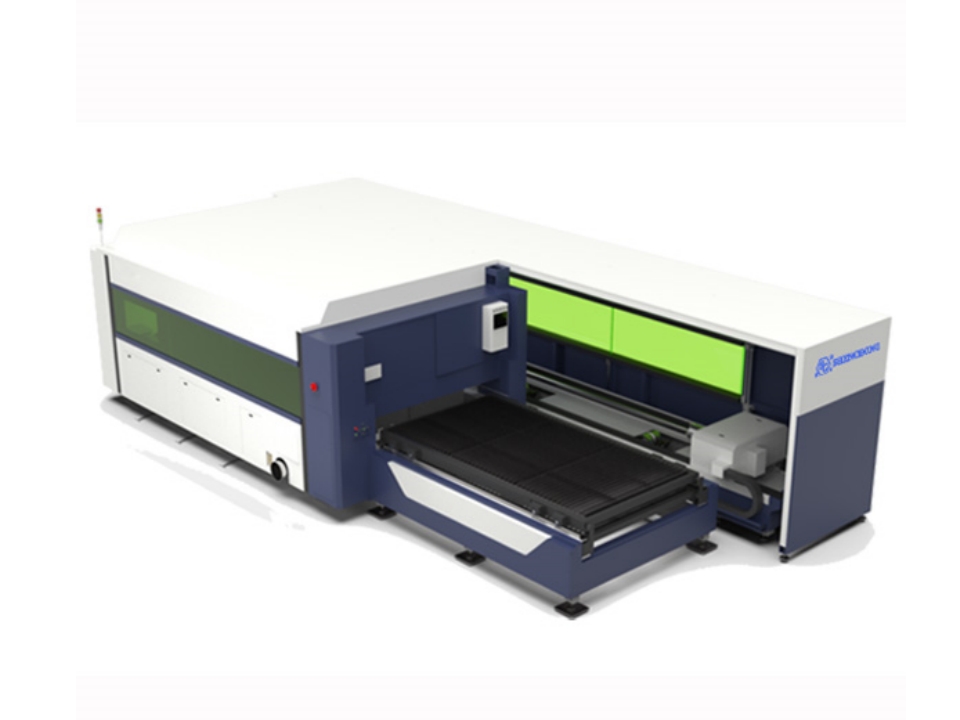

The metal sheet plate fiber laser cutting machine is a laser cutting machine designed specifically for cutting metal plate sheets. High quality, high speed, high precision, high efficiency, and equipped with a fully automatic CNC laser metal cutting system are its characteristics.

The metal sheet fiber laser cutting machine uses a high-power density laser beam to irradiate the cut material, causing it to be quickly heated to the vaporization temperature and evaporate to form holes. As the beam moves towards the material, the holes continuously form narrow slits, completing the cutting of the material.

Sheet metal laser cutting machine is the latest cutting technology in recent years. In the field of metal sheet metal cutting, from ultra-thin sheets at the micrometer level to tens of millimeters thick sheets, they can be perfectly and effectively cut. Compared to traditional plasma cutting machine, flame cutting machine, plate shearing machine, stamping machine, etc., sheet fiber laser cutting machine has higher efficiency and it is more automated.

SC SHENCHONG sheet fiber laser cutting machines include two series, SCM single table fiber laser cutting machine and SCDM double exchange worktable fiber laser cutting machine.

SCM single table sheet fiber laser cutting machine is cost effective series, and the SCDM double exchange platform fiber laser cutting machine is the high end series.

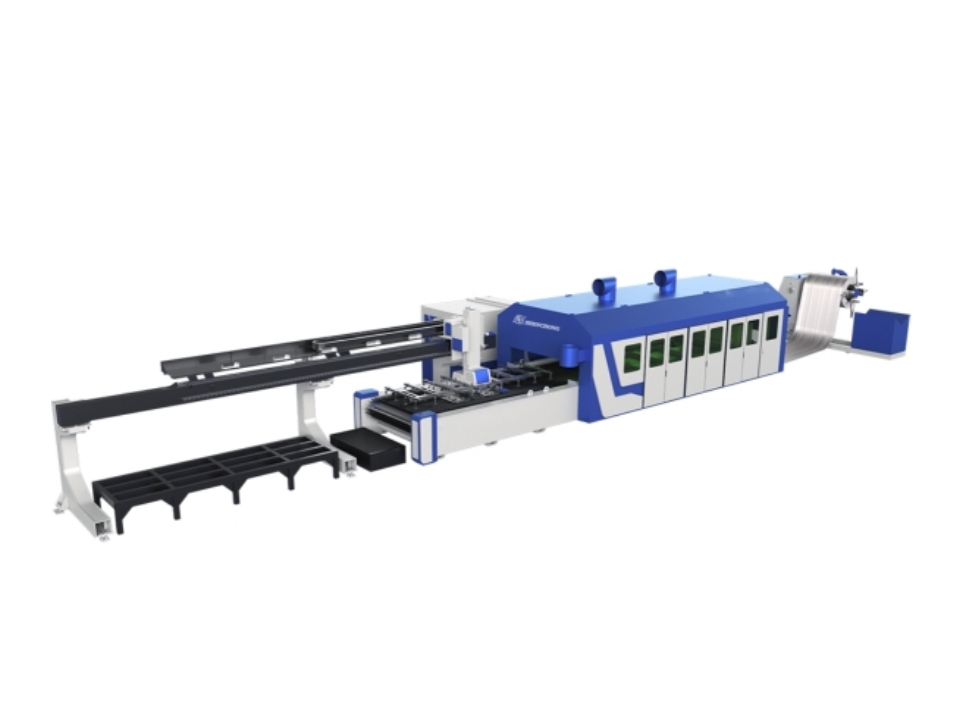

The tube fiber laser cutting machine is a laser cutting machine designed specifically for cutting metal tubes and pipes, which can efficiently complete the cutting process of metal pipes. In terms of cutting and processing pipes, pipelines, and structural steel, SHENCHONG specialized tube and pipe laser cutting machine is equipped with a professional laser cutting system, which is simple to operate and has high accuracy. At the same time, it can be equipped with a pushing system to reduce cutting costs and improve efficiency. It is widely used in industries such as sports equipment and oil pipelines, meeting various manufacturing needs and bringing value-added advantages to customers.

The tube fiber laser cutting machine can cut all metal pipes at high speed and precision, meeting the cutting requirements of irregular pipes such as round pipes, square pipes, and rectangular pipes. It also achieves high-speed and fully automatic cutting, improving cutting accuracy, achieving zero tailings cutting, and improving material utilization rate.

Tube fiber laser cutting machine includes two series. SCCT standard tube fiber laser cutting machine, which is the professional laser cutting machine specially designed to cut tube and pipes. SCCT-Q is the high end pipe laser cutting machine with loading and unloading function.

The tube and sheet fiber laser cutting machine is a new type of fiber laser cutting machine that combines the both functions of cutting metal sheet plates and cutting tube and pipes.

The processing speed of the tube and sheet fiber laser cutting machine is dozens of times that of traditional processing methods, which can achieve batch processing. The processing process can be converted to plate and tube cutting at any time, greatly improving production efficiency.

The customers can use one set of tube and sheet fiber laser cutting machine for dual purposes, greatly saving equipment purchase costs and workshop space. Tube and sheet fiber laser cutting machine is suitable for comprehensive processing and manufacturing factories.

SC SHENCHONG tube and sheet fiber laser cutting machine is the new generation laser cutting machine combines the both sheet cutting and tube cutting functions together. Buy one set of tube and sheet laser cutting machine and compete two types of cutting works.

Due to the thickness of many sheet metal coils are below 3mm, it is very suitable to use fiber laser for cutting. Uncoiling and leveling laser cutting machine combines the decoiling and leveling line and laser cutting machine to improve the cutting efficiency.

Multiple laser cutting heads controlled by the system dynamically follow the cutting on the laser cutting platform, uncoiling and leveling laser cutting machine replaces traditional presses and molds, using coil materials for continuous production, without causing loss of material heads and tails during single piece production.

Breaking through the process bottleneck of the original laser cutting equipment that can only cut a single sheet, it is possible to use a laser cutting machine to fly cut (follow cutting) the coil during the material movement, solving the problem of rapid cutting of continuous metal and non-metal strips without molds.

The efficient optimization of layout software and multi-channel programming control software of SC SHENCHONG uncoiling and leveling laser cutting machine have maximized the laser cutting technology without overlapping edges, effectively improving the utilization rate of materials.

Laser is a laser generator that emits an ultra dense laser beam, which is irradiated on a metal plate by a spot. The material is melted or gasified at high temperatures, and then blown away by high-pressure gas to achieve slitting. The cutting is then achieved through X, Y, and Z axis linkage.

Laser is converted from electrical energy to light energy, as the conversion between energy and energy cannot be 100%. Therefore, while some electrical energy is converted into light energy, the other part becomes thermal energy.

At present, the electro-optical conversion rate of fiber lasers is 25% -35%. The better the performance of the laser, the higher the ratio of its electro-optical conversion rate. Of course, relatively speaking, the larger the proportion of electro-optic conversion rate, the smaller the energy consumption. The lower the proportion of electro-optic conversion rate, the greater its energy consumption.

That’s why customers always focus on laser generator brand when they purchase laser cutting machines. IPG and Raycus are laser generator brands commonly used in the mainstream market.

Fiber laser cutting machines are most suitable for cutting metal sheets up to 20mm. If the thickness is too thick, the return on investment is not appropriate. If the sheet metal plate thickness is too large, and the accuracy requirement is not high, customers can choose plasma cutting machine or flame cutting machine, which can cut thick metal plates.

The maximum thickness of metal that a fiber laser cutting machine can cut is determined by the power of the laser generator. In theory, the higher the laser power, the greater the thickness that can be cut. For example, the maximum thickness of a 3000W fiber laser cutting machine can cut is 20mm carbon steel, 10mm stainless steel, 8mm aluminum plate, and 8mm copper plate.

At present, there are many high-power fiber laser cutting machines available on the market, such as the 50000w fiber laser cutting machine, which can stably cut 50mm carbon steel plates, but in this case, the fiber laser cutting machine price is super expensive.

When selecting a fiber laser cutting machine, it is also necessary to consider customers’ needs, such as the thickness of the material to be cut or the factors that affect the power of the purchased equipment. Generally, fiber laser cutting machine manufacturers will combine the needs of customers to match. When purchasing a fiber laser cutting machine, it is also necessary to pay attention to the selection of power. Higher power means that the cutting speed can be improved, and thicker plates can also be cut. However, when selecting power, it is also necessary to consider the operating scenario. The higher power also means the higher fiber laser cutting machine price.

When selecting fiber laser cutting machines, the first thing to pay attention to is the core components. For laser cutting machines, what will affect the quality of the laser lies in the chiller, cutting head, and laser generator. Each different brand will have differences in price. In order to effectively demonstrate stability and ensure after-sales service, it is necessary to first select a professional manufacturer correctly, which can ensure high-quality quality and avoid frequent malfunctions during later use, and will not affect normal use.

According to the design standards, taking the laser equipment of SHENCHONG as an example, the designed service life can reach more than ten years, because the core laser of the laser equipment can have a service life of over 100000 hours. The root cause of many customer’s equipment failures is that the operators did not operate the fiber laser cutting machine equipment according to the required specifications or did not regularly maintain the equipment. In the long run, the lifespan of fiber laser cutting machines will gradually be shortened, while also increasing their after-sales costs.

Fiber laser cutting machine price is related to the design, configuration, power, function… SHENCHONG fiber laser cutting machine for sale price range from USD 20000 to USD 95000. If you need other automation system to match with our fiber laser cutting machine, the price would be higher. Please contact with us for more details.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.