Brand: SC SHENCHONG

Model: WEK Hydraulic CNC press brake

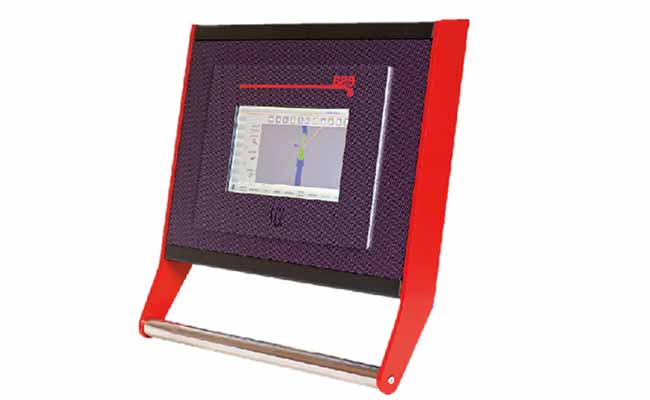

CNC Controller: ESA S630

Standard Axis: 4+1 axis, (Y1,Y2,X,R,+V)

Optional Axis: 6+1 axis, 8+1 axis

Price Range: $20000-$45000/Set

After Sale: 3 Years

Lead Time: 25-45 Working Day

WEK series hydraulic CNC press brake machine is a press brake that controlled by a CNC control system and uses an electro-hydraulic proportional valve to adjust the Y1 and Y2 axes, achieving high-precision bending. Due to the formation of closed-loop control, the CNC system can adjust the position of the ram in real-time, and the accuracy of all Y1 and Y2 axes can reach ± 0.01mm.

WEK series CNC hydraulic press brake is the most popular press brake type in the current bending market. Our standard configuration is 4+1 axis, CNC control the ram (Y1,Y2 axis), control the backgauge forward and back (X axis), control the backgauge up and down (R axis), control the table crowning (V axis).

SC SHENCHONG is a professional CNC hydraulic press brake machine manufacturer, and we have production capability to produce press brake from 63 tons to 1000 tons.

|

Model |

Nominal Pressure (kN) |

Length of Table (mm) |

Distance Between Housings (mm) |

Throat Depth (mm) |

Stroke (mm) |

Open Height (mm) |

Main Motor (kw) |

|

WEK 63T/2500MM |

630 |

2500 |

2000 |

320 |

160 |

400 |

7.5 |

|

WEK 63T/3200MM |

630 |

3200 |

2660 |

320 |

160 |

400 |

7.5 |

|

WEK 100T/3200MM |

1000 |

3200 |

2660 |

400 |

200 |

450 |

11 |

|

WEK 125T/3200MM |

1250 |

3200 |

2660 |

400 |

200 |

450 |

11 |

|

WEK 125T/4000MM |

1250 |

4000 |

3200 |

400 |

200 |

450 |

11 |

|

WEK 160T/3200MM |

1600 |

3200 |

2660 |

400 |

200 |

470 |

15 |

|

WEK 160T/4000MM |

1600 |

4000 |

3200 |

400 |

200 |

470 |

15 |

|

WEK 200T/3200MM |

2000 |

3200 |

2660 |

400 |

200 |

470 |

15 |

|

WEK 200T/4000MM |

2000 |

4000 |

3200 |

400 |

200 |

470 |

15 |

|

WEK 200T/6000MM |

2000 |

6000 |

4800 |

400 |

200 |

470 |

15 |

|

WEK 250T/3200MM |

2500 |

3200 |

2660 |

400 |

250 |

490 |

18.5 |

|

WEK 250T/4000MM |

2500 |

4000 |

3200 |

400 |

250 |

490 |

18.5 |

|

WEK 250T/6000MM |

2500 |

6000 |

4800 |

400 |

250 |

490 |

18.5 |

|

WEK 300T/3200MM |

3000 |

3200 |

2660 |

400 |

250 |

500 |

22 |

|

WEK 300T/4000MM |

3000 |

4000 |

3200 |

400 |

250 |

500 |

22 |

|

WEK 300T/6000MM |

3000 |

6000 |

4800 |

400 |

250 |

500 |

22 |

|

WEK 400T/4000MM |

4000 |

4000 |

3200 |

400 |

300 |

605 |

30 |

|

WEK 400T/5000MM |

4000 |

5000 |

4000 |

400 |

300 |

605 |

30 |

|

WEK 400T/6000MM |

4000 |

6000 |

4800 |

400 |

300 |

605 |

30 |

|

WEK 500T/4000MM |

5000 |

4000 |

3200 |

600 |

300 |

615 |

37 |

|

WEK 500T/5000MM |

5000 |

5000 |

4000 |

600 |

300 |

615 |

37 |

|

WEK 500T/6000MM |

5000 |

6000 |

4800 |

600 |

300 |

650 |

37 |

|

WEK 600T/5000MM |

6000 |

5000 |

4000 |

600 |

300 |

650 |

37 |

|

WEK 600T/6000MM |

6000 |

6000 |

4800 |

600 |

300 |

650 |

37 |

|

WEK 800T/5000MM |

8000 |

5000 |

4000 |

700 |

350 |

710 |

55 |

|

WEK 800T/6000MM |

8000 |

6000 |

4800 |

700 |

350 |

710 |

55 |

|

WEK 1000T/6000MM |

10000 |

6000 |

4800 |

700 |

350 |

730 |

55 |

ESA-S630 CNC system can control (4+1) axes, with basic configuration to control Y1,Y2,X,R+V axis. It can customize input or output, and freely define axis types. The workbench compensation (V) axis is standard configuration. 10 inch color touch control screen can display and edit more bending data on one page.

Two modes of programming methods: data programming and graphic programming are more convenient, and equipped with graphic programming software, which can automatically calculate the bending process and prevent collision interference detection, making the bending process simpler and more efficient.

WEK Serie CNC hydraulic press brake adopts mechanical table crowning, which is V axis controlled by CNC controller. It can automatically adjust and compensation the pressure deflection of the working table during the bending process. By using CNC table crowning, SC SHENCHONG hydraulic CNC press brake and ensure the bending straightness and high angle consistency.

X-axis of the back gauge adopts ball screw and linear guide, driven by digital AC servo motor, and the back gauge has retraction control function. Double linear guideway on the press brake backgauge helps to improve the bending precision.

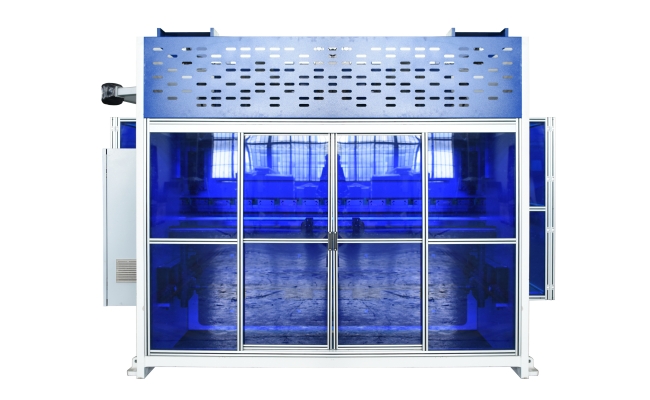

Side protection ensure the operator’s working security. Rear door protection can be locked during the working process. Also customers can choose light curtain protection instead of rear door protection.

Cooling system is the standard configuration on SC SHENCHONG CNC hydraulic press brake machine, which can cool down the hydraulic oil temperature. When hydraulic oil temperature is too high, press brake machine would not work stably, and in this case, cooling system on the cnc press brake helps to ensure the machine working quality and efficiency.

CNC bending machine is a universal bending equipment that is required by manufacturers who need to bend sheets.

Press various types of metal products. CNC hydraulic press brake machines can process various metal materials, such as steel, aluminum, copper, titanium, etc. By uniformly applying force, these materials can be bent into specific shapes, thereby manufacturing various types of metal products. In the fields of manufacturing machinery, automobiles, aerospace, and electronic equipment, hydraulic press brake machines are commonly used for manufacturing components.

As a CNC hydraulic press brake manufacturer, SC SHENCHONG has more than 25 years press brake machine production experience, and we have more than 20 years exporting experience. During the years of design, manufacturing, service, we provide stable high quality CNC hydraulic press brake and fast respond after-sale.

Since we have more than 20 years exporting experience, we can ship our machine to your country safe and quickly. We cooperate with many shipment forwarders, and we are able to provide FOB, CIF, or even door to door shipment service. No matter if this is the first time you buy machines from China, we can help to solve the shipment problems for you.

CNC hydraulic press brake can be connected with bending robot to improve the manufacturing automation level. SC SHENCHONG has robotic engineers to design the bending robot technical proposal and to produce the automatic robotic press brake.

SC SHENCHONG servo bending follower is an automatic tool that assists bending workers in flipping up during the bending process. Unlike other traditional sheet follower devices on the market, SC Machinery servo bending follower can be matched with any brand CNC press brake machines.

Twisted axis press brake machine: As the name suggests, the operation of a bending machine is generated by a central axis

CNC press brake machine: CNC press brake machine relies on the synchronization of servo synchronous proportional valves on both sides, which not only has high synchronization accuracy, but also has real-time error feedback. The bending slider has strong anti bias load capacity, and the bending effect obtained is also better.

The biggest difference is the different structure that ensures synchronization on both sides of the bending slider.

The torsion axis synchronous bending machine relies on the mechanical balance shaft for forced synchronization, with low synchronization accuracy and no error feedback. The bending slider has poor anti bias load capacity. The stability and accuracy of a machine are affected by multiple factors. For example: cylinder accuracy, slider accuracy, synchronous shaft accuracy, etc. Moreover, prolonged use of the worm gear can also consume wear and affect positioning accuracy. So the bending machine with a torsion axis synchronous structure becomes more and more inaccurate as it is used, and needs to be readjusted every time it is used.

The electro-hydraulic servo CNC press brake machine relies on synchronous proportional valves on both sides, with high synchronization accuracy, real-time error feedback, and strong anti bias load capacity of the bending slider; So as long as the new machine is installed and debugged, the electro-hydraulic servo CNC press brake machine can be used better and better in the future, and the accuracy can be maintained continuously.

Twist axis synchronous bending machine: The opening height of the slider is fixed, and every time it is opened, it needs to move from the highest point to the lowest point. Moreover, the opening height is too small, and some special workpieces cannot be completed, so the work efficiency is not high.

Electrohydraulic servo CNC synchronous bending machine: The opening height of the slider can be digitally controlled by a grating ruler, eliminating the need to return to the highest point each time, thereby saving time and improving processing efficiency.

CNC controller functions

Twist axis synchronous press barke machine: The control system generally has a single function, and workers need to repeat calculations in order to program.

Electrohydraulic servo CNC synchronous bending machine: The CNC system software integration is very high, and workers can program the required workpiece more intuitively and quickly.

Different press brake series have different price. SC SHENCHONG CNC hydraulic press brake includes WEK CNC hydraulic press brake and WSK Energy Saving CNC press brake. WEK is the normal CNC press brake type and WSK is the eco-friendly type with main servo motor configuration.

Please feel free to contact with us to get the press brake price.

Yes, we have hybrid servo press brake and robotic press brake, which are latest generation CNC press brake series. Hybrid servo press brake adopts two main servo motors and separate oil tanks, which reduce the energy consumption and can improve the bending efficiency. Robotic press brake can connect with different robot brands and do not need to use human to operate.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.