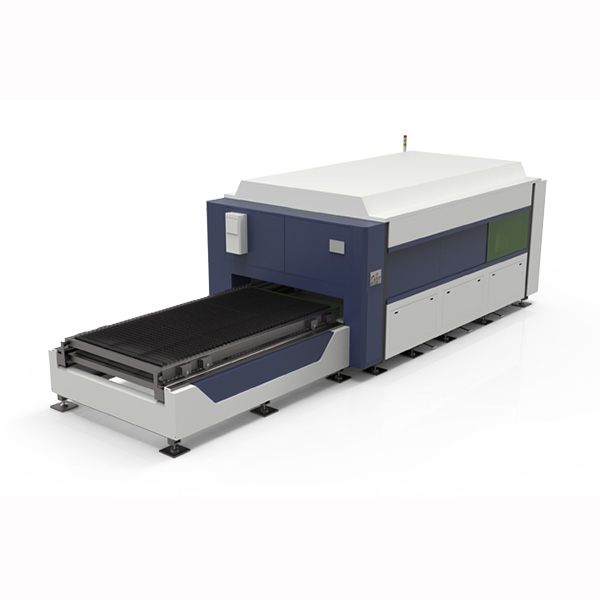

SHENCHONG automatic metal deburring machine is the machine to automatically deburr, polish, rounded corners, and wire draw the metal plates.

Used for batch burr removal, sharp edge rounding, and surface polishing of workpieces in turret punching machines and laser cutting and cutting workers.

The core polishing station adopts a strong and wide sanding belt combined with a flexible grinding roller group for continuous and uniform polishing effect.

The efficient and clean processing characteristics are suitable for the next process of workpiece folding, surface spraying, welding, etc., saving the troubles of low efficiency, flying dust, and inconsistent workpiece polishing caused by manual polishing.

The conveying system adopts a vacuum adsorption type, which can meet the batch processing of multiple specifications with the same thickness.

|

Model |

|||

|

Workpiece Width |

1000mm |

Grinding Medium |

Flexible grinding brush roller and wide sanding belt |

|

Equipment Opening |

0-50mm |

Number of Flexible Grinding Rollers |

6 |

|

Feeding Speed |

0.8-5m/min |

weight |

4000kgs |

The entire frame is welded and sandblasted, and the surface of the entire machine is treated with powder spraying, which has good rigidity and durability.

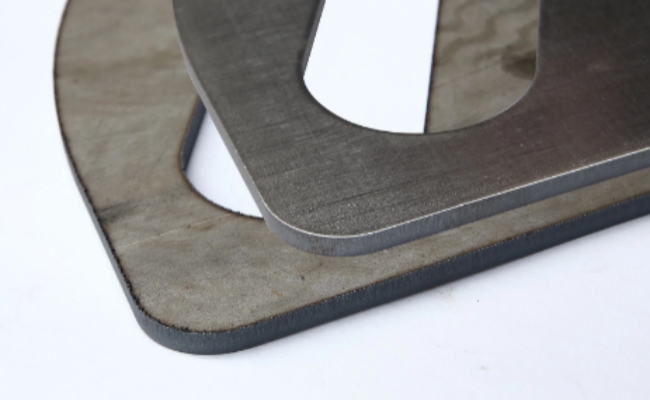

Strong and wide sanding belt polishing front workstation, used for pre-treatment of large burrs or surface drawing, servo lifting, precision polishing.

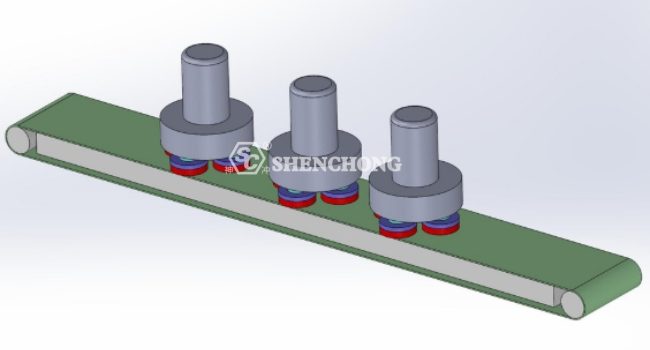

Six sets of planetary flexible grinding rollers are used, with adjacent groups rotating in both positive and negative directions. The grinding assembly undergoes uniform horizontal movement and overall revolution, ensuring that the abrasive sand cloth strip fully contacts every corner of the workpiece.

Vacuum conveying platform, capable of processing workpieces with minimal surface holes of 60x60mm.

The high-speed rotating parts adopt imported bearings.

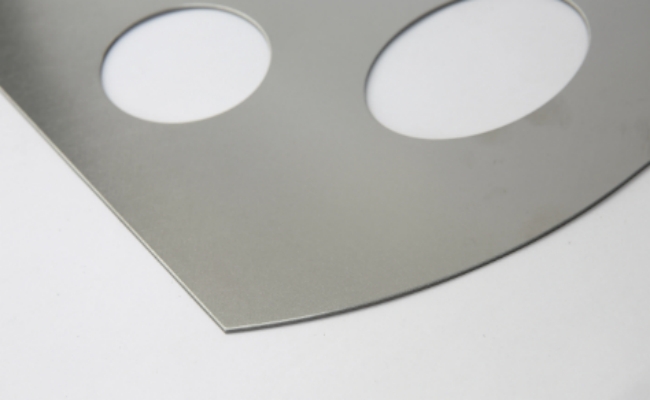

Only applicable to the corners and edges of the workpiece and holes, with minimal surface impact. The film plate can be processed with film, and can be used for surface micro forming or surface machining of parts.

Long service life and uniform consumption of polishing consumables.

Convenient and intuitive to operate, the device is equipped with an LED light source to observe the internal processing condition.

The touch screen friendly operation interface allows for flexible setting of polishing parameters for different workpieces, making the operation simple.

Core Polishing Station

1 set of sanding belt and 3 sets of brush discs

1. Carbon steel, stainless steel, aluminum, copper and other metal materials.

2. Allow workpiece processing with protective film while retaining the protective film to a greater extent.

3. Remove burrs from workpieces with a thickness range of 0.5mm-50mm and a width range of 1000mm.

4. The large chamfer process before spraying requires a maximum of 2mm.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.