Brand: SC

Suction cup: ANFH0

Vacuum generator: SMC

Cylinder: SMC

Relay: Schneider/Omron

PLC: SIEMENS

After Sale: 3 Years

Lead Time: 50-80 Working Day

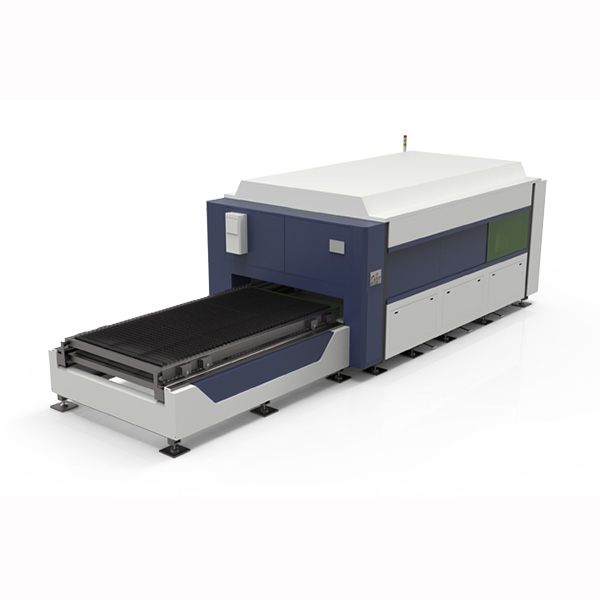

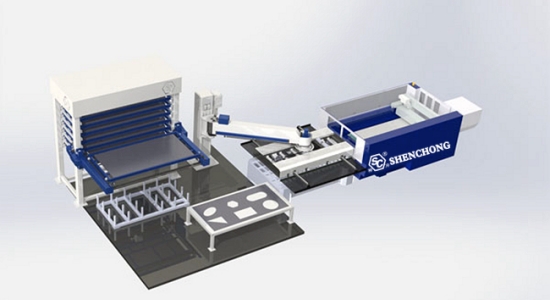

Sheet metal automatic loading unloading system is the machine to intelligently help the raw material and finished workpieces load and unload in the sheet metal processing industry. Using automatic loading unloading machine can improve production efficiency and reduce labor costs.

Automatic loading and unloading system technology refers to the use of automated equipment such as robotic arms to remove sheet metal sheets from the material rack or inventory area, place them on processing equipment for processing, and then remove the processed sheet metal sheets from the processing equipment and place them back into the material rack or inventory area. This process is completely automated by the equipment, without the need for manual intervention, greatly improving production efficiency.

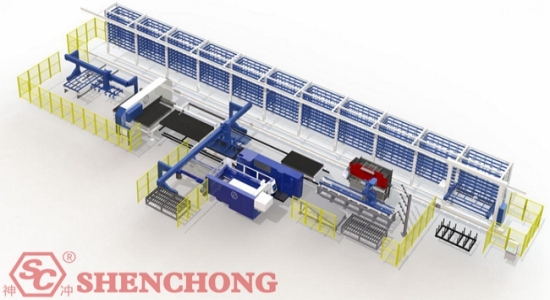

The application field of automatic loading and unloading technology is very extensive, especially in large-scale or high-precision sheet metal processing, where its advantages can be fully utilized. Currently, sheet metal automatic loading unloading device is commonly connected with laser cutting machine, sheet metal storage system, panel bender, turret punch press, front feeding shearing machine.

|

Model |

17SXL150 |

17SXL300 |

17SXL500 |

|

Rated load without material distribution |

250kg |

400kg |

600kg |

|

Rated load during material distribution |

150kg |

300kg |

500kg |

|

The maximum size of the workpiece during loading |

3000×1500mm |

3000×1500mm |

3000×1500mm |

|

The maximum thickness of the workpiece during loading |

4—7mm |

8—14mm |

14—20mm |

|

Overall dimensions |

5800×1850X2700 |

6000×2000X2900 |

6000×2000X3000 |

|

Total weight |

1700kg |

3500kg |

4000kg |

|

Turning radius of the rotary arm |

2150mm |

3150mm |

3150mm |

|

Rotation angle |

0°-180° |

||

|

Minimum size of loaded workpiece |

1000×1000mm |

||

|

The minimum size of the workpiece during material separation |

150x150x4mm |

150x150x8mm |

150x150x14mm |

|

Power of lifting motor |

3KW |

4KW |

5.5KW |

|

Rotating motor |

0.55KW |

0.55KW |

0.75KW |

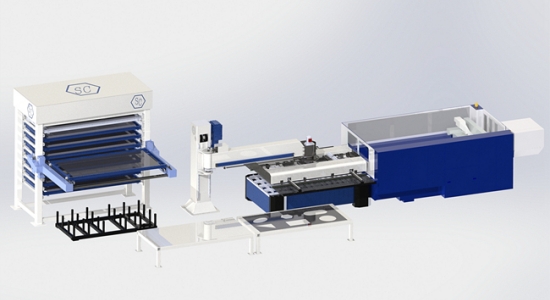

One click feeding, automated operation, and processing efficiency improvement of over 20%.

High precision swing arm positioning control ensures accurate loading position of the sheet metal.

180 ° wide angle, more flexible layout of workstations and equipment;

Equipped with rich safety sensing modules to ensure safe operation.

SC SHENCHONG automatic feeding module completely replaces manual labor, which has high efficiency, accurate positioning, labor-saving, and safety assurance features to effectively solve the problem of manual loading or driving.

Waste of time, labor costs, safety hazards, and other issues related to forklift loading.

|

Double Beam Truss (V Rail) |

|

Model |

350-750 |

800-1200 |

1250-1800 |

|

Operation Speed (m/min) |

Horizontal |

60 |

60 |

40/60 |

|

|

Vertical |

30 |

30 |

20/30 |

||

|

Main Motor (kw) |

Horizontal |

3.5*2 |

3.5*2 |

3.5*2 |

|

|

Lift |

5.5-7.5 |

7.5-11 |

11-15 |

||

|

Single Beam Truss (V Rail) |

|

Model |

150 |

300 |

|

|

Operation Speed (m/min) |

Horizontal |

80 |

80 |

|

|

|

Vertical |

40 |

40 |

|

||

|

Main Motor (kw) |

Horizontal |

2 |

5.5 |

|

|

|

Lift |

2 |

5.5 |

|

||

|

Single Beam Truss (Gear and rack) |

|

Model |

150 |

300 |

|

|

Operation Speed (m/min) |

Horizontal |

60 |

60 |

|

|

|

Vertical |

30 |

30 |

|

||

|

Main Motor (kw) |

Horizontal |

2 |

2 |

|

|

|

Lift |

2 |

3 |

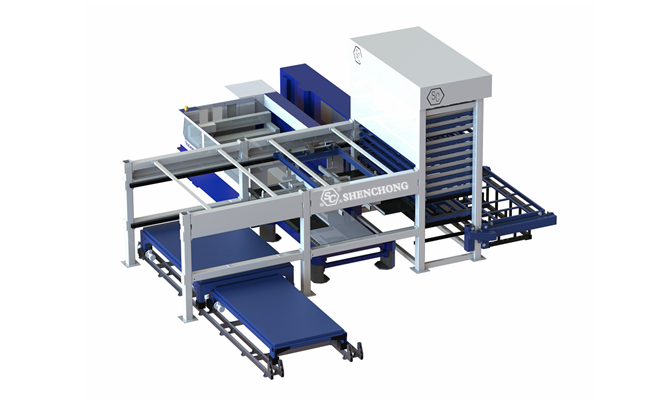

Configure two sets of raw material trays and finished product trays to achieve automatic retrieval and storage of raw materials and finished products.

Economically efficient, meeting the automation needs of medium to large batches and few varieties of boards.

The reasonable structural design and concise control logic accelerate the entire cycle feeding cycle.

During batch cutting operations, traditional machines require frequent loading/unloading, plate positioning, and other operations, which wastes labor costs and is inefficient. The fully automatic loading and unloading module can replace manual loading/unloading, and stack the cut finished materials for centralized sorting by customers.

Automatic detection of board presence, separation of boards, and dual layer thickness measurement of boards.

SC SHENCHONG automatic loading unloading system adopts both suction cup and fork mechanism. Suction cup is used to load the sheet metal plate and the fork is used to unload the plates.

SC SHENCHONG automatic loading unloading system moving mechanism can choose chain drive, gear and rack or V-wheel.

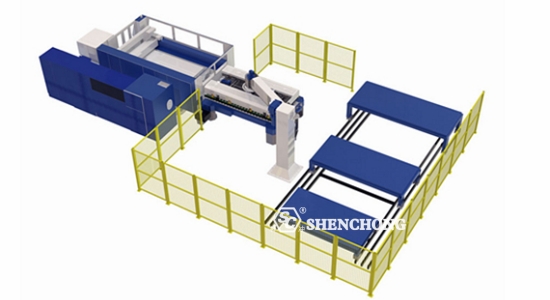

Compared to manufacturers of loading and unloading equipment, as a manufacturer of laser cutting machines, automatic storage system, panel bender, plate shearing machine, we can better match all these machines and achieve perfect communication and docking with them.

One of the earliest China manufacturers to independently develop, produce, and apply a complete set of flexible production lines.

The independently developed anti fall function of the equipment ensures that each node has an anti fall mode, thereby fully ensuring the personal safety of equipment operators and the safety of the equipment itself.

Based on modular design, it can be modularized and expanded at any time, thereby achieving single machine and multi machine parallel, series and other cutting flexible production line systems.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.