4 roller bending machine is suitable for the rolling and forming of metal sheets. It can roll circular, arc-shaped, and conical workpieces within a certain range, and has a pre-bending function at the end of the sheet. The remaining straight edges are small, and the work efficiency is high. 4 roller plate bending machine can also roughly level the metal sheets.

The upper roller position of the four roll plate rolling machine is fixed, while the lower roller moves upwards in a straight line to clamp the steel plate. Adjust the curvature radius of the drum by moving the rollers on both sides in a straight or curved line upwards. The roller motion forms of the four roller plate rolling machine and three roll plate rolling machines are different, but the working principle is the same. Both use the principle of three-point circle determination to roll with different radii. However, the straightness of the pre-bent edge and roundness of the correction circle of the four roll plate bending machine are better than those of the three roll bending machine.

|

Model |

Plate Length (mm) |

Min.diameter= top roller Φ×5 |

Min. diameter= top roller Φ×(1.5~2) |

Top roller (mm) dia |

Bottom roller (mm) |

Side roller dia. (mm) |

Main motor (Kw) |

Rolling speed (m/ min) |

Machine Size(LxWxH) (mm) |

Weight(ton) |

||

|

without prebend |

with prebend |

without prebend |

with prebend |

|||||||||

|

W12-12×2000 |

2000 |

12 |

9 |

6 |

220 |

200 |

160 |

7.5 |

3-5 |

4500×1500×1400 |

5 |

|

|

W12-16×2000 |

2000 |

16 |

12 |

8 |

260 |

240 |

200 |

11 |

3-5 |

4100×1700×1800 |

6.7 |

|

|

W12-20×2000 |

2000 |

20 |

16 |

12 |

280 |

260 |

220 |

18.5 |

3-5 |

4600×1950×1900 |

9.6 |

|

|

W12-25×2000 |

2000 |

25 |

20 |

16 |

310 |

290 |

250 |

22 |

3-5 |

4800×2000×2000 |

11.3 |

|

|

W12- 30×2000 |

2000 |

30 |

25 |

20 |

360 |

330 |

270 |

30 |

3-5 |

5100×2100×2000 |

13 |

|

|

W12-8×2500 |

2500 |

8 |

6 |

4 |

220 |

200 |

160 |

7.5 |

3-5 |

5000×1500×1400 |

6 |

|

|

W12-12×2500 |

2500 |

12 |

9 |

6 |

250 |

230 |

180 |

11 |

3-5 |

5100×1500×1400 |

7.1 |

|

|

W12-16×2500 |

2500 |

16 |

12 |

8 |

280 |

260 |

220 |

15 |

3-5 |

5100×1950×1900 |

10.2 |

|

|

W12-20×2500 |

2500 |

20 |

16 |

12 |

330 |

310 |

250 |

22 |

3-5 |

5300×2000×2000 |

12 |

|

|

W12-25×2500 |

2500 |

25 |

20 |

16 |

360 |

330 |

270 |

30 |

3-5 |

5600×2100×2000 |

15 |

|

|

W12-30×2500 |

2500 |

30 |

25 |

20 |

390 |

360 |

290 |

37 |

3-5 |

5600×2250×2100 |

18 |

|

|

W12-40×2500 |

2500 |

40 |

35 |

30 |

470 |

440 |

380 |

45 |

3-5 |

6100×2550×2700 |

25.5 |

|

|

W12-50×2500 |

2500 |

50 |

40 |

35 |

510 |

480 |

410 |

55 |

3-5 |

6100×3100×2700 |

36 |

|

|

W12-60×2500 |

2500 |

60 |

50 |

40 |

560 |

530 |

450 |

75 |

3-5 |

6500×3200×3000 |

48 |

|

|

W12-6×3000 |

3000 |

6 |

5 |

4 |

220 |

200 |

160 |

7.5 |

3-5 |

5500×1500×1400 |

7 |

|

|

W12-8×3000 |

3000 |

8 |

6.5 |

5 |

250 |

230 |

180 |

11 |

3-5 |

5600×1500×1400 |

9 |

|

|

W12-12×3000 |

3000 |

12 |

9 |

6 |

280 |

260 |

220 |

15 |

3-5 |

5700×1950×1900 |

12 |

|

|

W12-16×3000 |

3000 |

16 |

12 |

8 |

330 |

310 |

250 |

22 |

3-5 |

2900×2000×2000 |

14 |

|

|

W12-20×3000 |

3000 |

20 |

16 |

12 |

360 |

330 |

270 |

30 |

3-5 |

6100×2150×2000 |

17 |

|

|

W12-25×3000 |

3000 |

25 |

20 |

16 |

390 |

360 |

290 |

37 |

3-5 |

6100×2250×2100 |

20 |

|

|

W12-30×3000 |

3000 |

30 |

25 |

20 |

410 |

380 |

320 |

45 |

3-5 |

6300×2500×2400 |

23 |

|

|

W12-35×3000 |

3000 |

35 |

30 |

25 |

470 |

440 |

380 |

45 |

3-5 |

6600×2550×2700 |

28 |

|

|

W12-40×3000 |

3000 |

40 |

35 |

30 |

510 |

480 |

410 |

55 |

3-5 |

6600×2600×2750 |

39 |

|

|

W12-50×3000 |

3000 |

50 |

40 |

35 |

560 |

530 |

450 |

66 |

3-5 |

6600×3200×3000 |

51 |

|

|

W12-60×3000 |

3000 |

60 |

50 |

40 |

650 |

620 |

520 |

75 |

3-5 |

7000×3300×3400 |

74 |

|

|

W12-70×3000 |

3000 |

70 |

60 |

50 |

700 |

670 |

550 |

90 |

3-5 |

7200×3500×3600 |

89 |

|

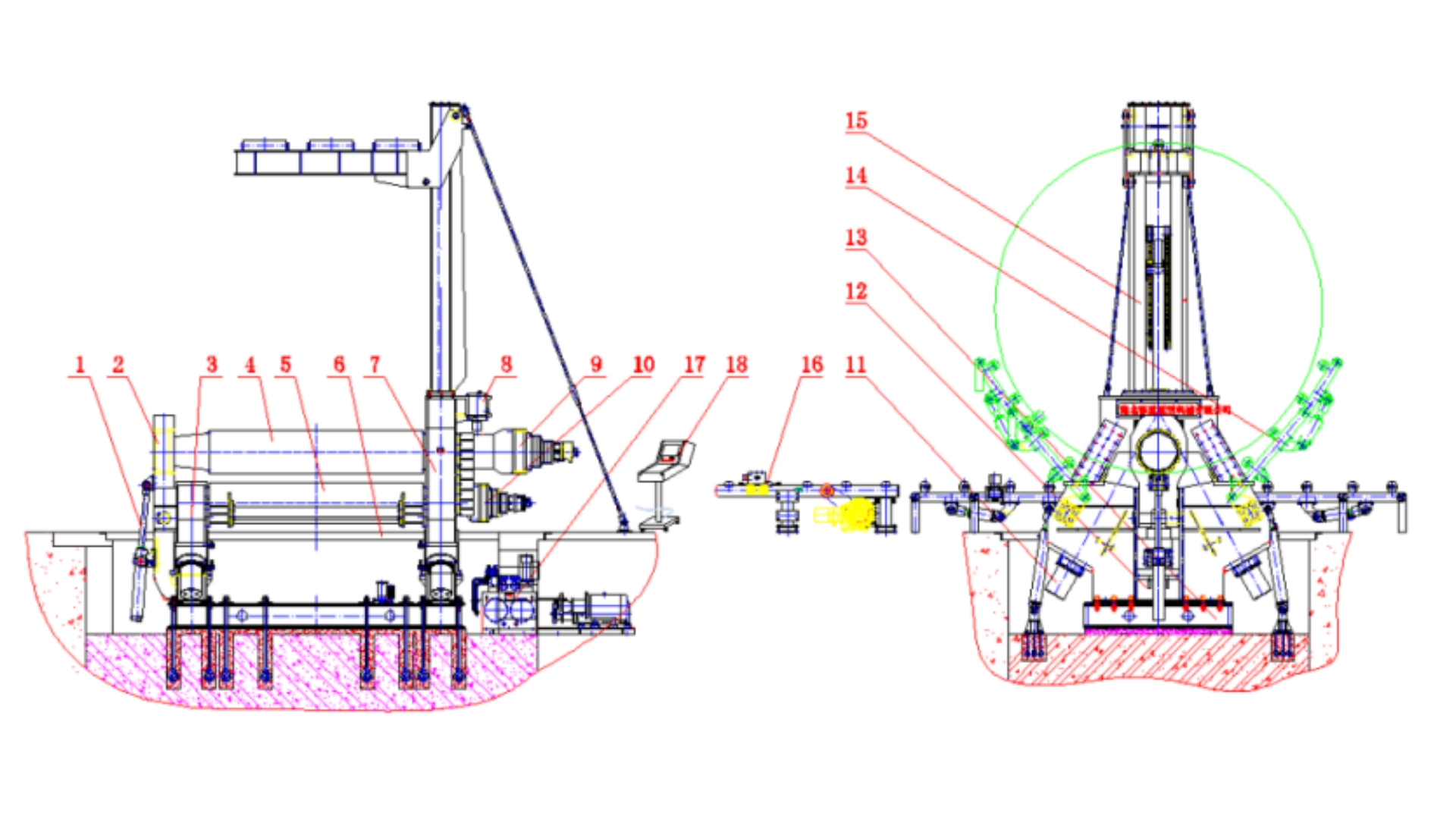

1.Drop end cylinder 2.Drop end 3.Left frame 4.Upper roll 5.Side roll 6.Lower roll 7.Right frame 8.Balancing system 9.Upper roll driven device 10.Lower roll driven device【optional】 11.Side roll cylinder 12.Lower roll cylinder 13.Bottom frame 14.Side support system【optional】 15.Top support system【optional】 16. Electric feeding electric roll【optional】 17.Hydraulic system 18.Electronic control system

Working rolls are made of high-strength high-quality steel 42CrMo material, after forging, roughing, quenching and tempering, HB240 ~ 300, finishing after the intermediate frequency quenching HRC47-58, according to JB/ZG4289-86 roll steel standards, the stiffness is consistent (1/700 ~1/1000) L. The distance between the centerlines of the sides rack. And strictly in accordance with the working process of manufacturing all the standard roll manufacturing, to ensure its comprehensive mechanical properties.

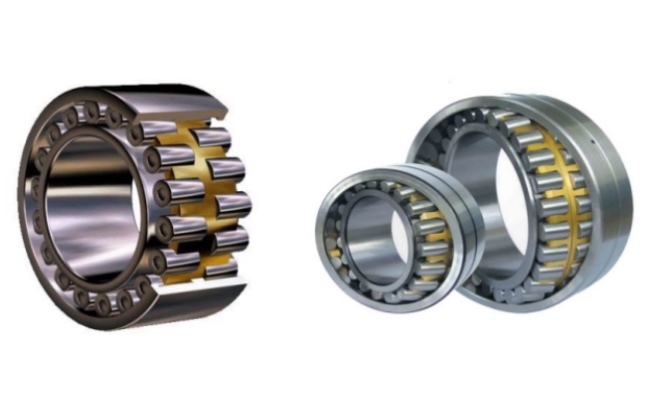

The four rollers rolling machine adopts very durable double-row self-aligning roller bearings recommended by the industry for each roller.

For SC 4 rollers plate bending machine, each oil circuit is routed with two relief valve to control pressures. The one is mainly to control the main cylinder pressure, and the other one is mainly to control the overturning cylinder and balancing cylinder pressure.

In order to ensure the synchronization accuracy of the main oil cylinders at both ends of each moving working roll, high-precision displacement sensors are installed on the left and right racks and the tilting frames. Through the pressure sensors, the microcomputer control system detects and adjusts the movements of the main oil cylinder pistons to achieve the precision of the both working roll ends.

The base and frame are the main parts of the equipment. SC SHENCHONG plate rolling machine frame selects high-quality steel, uses CNC cutting, grinding and welding, and then sends the welded structural parts to the professional heat treatment factory for stress relief annealing—CNC lathe machining, eliminating welding stress, so that it has enough strength and stiffness, to ensure normal operation at full load. All records of the workpiece are included in the quality tracking system.

SC 4 roller plate rolling machine control system is equipped with an automatic rolling program, which can realize one-button operation. It can automatically roll and roll once at a time. It also has data number, storage and recall functions, and can store hundreds of data. Various specifications of automated rolling. The system is compatible with manual operation programs and can be manually operated when needed.

As a 4 roller plate rolling machine manufacturer, SC SHENCHONG has more than 25 years plate rolling machine production experience, and we have more than 20 years exporting experience. During the years of design, manufacturing, service, we provide stable high quality CNC plate rolling machine and fast respond after-sale.

CNC four rollers bending roll is suitable to connect with automatic feeding and unloading system to improve the plate rolling efficiency. SC has the professional engineers to design and install the automatic plate rolling machine production line for customers.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.