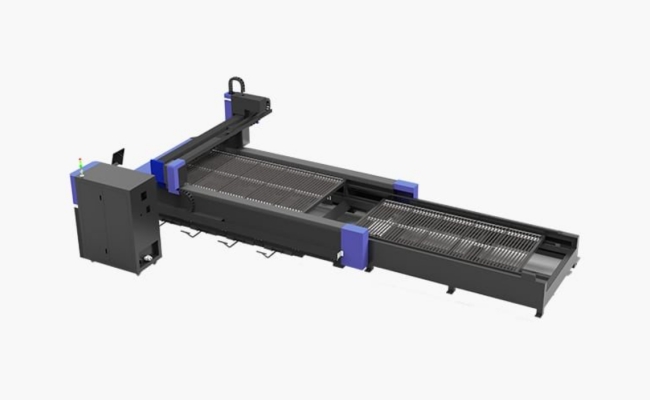

The tube and sheet fiber laser cutting machine is a dual-purpose fiber laser cutting machine that can be used for efficient cutting of metal tube and sheet plates. It adopts a sturdy steel bed, frame drive system, and a professional tube and sheet plate laser cutting CNC system, ensuring good cutting precision and efficiency of the laser cutting machine. Tube and sheet fiber laser cutting machines is gradually playing a role in the metal manufacturing industry, such as metal signage, interior decoration, sheet metal processing, etc.

The pipe and sheet metal fiber laser cutting machine integrates sheet cutting and pipe cutting into one laser cutting machine. According to actual production needs, it can be equipped with fiber laser generators of various powers (1000-6000W). Of course, you can also choose to add an exchange workbench and a fully enclosed protective cover.

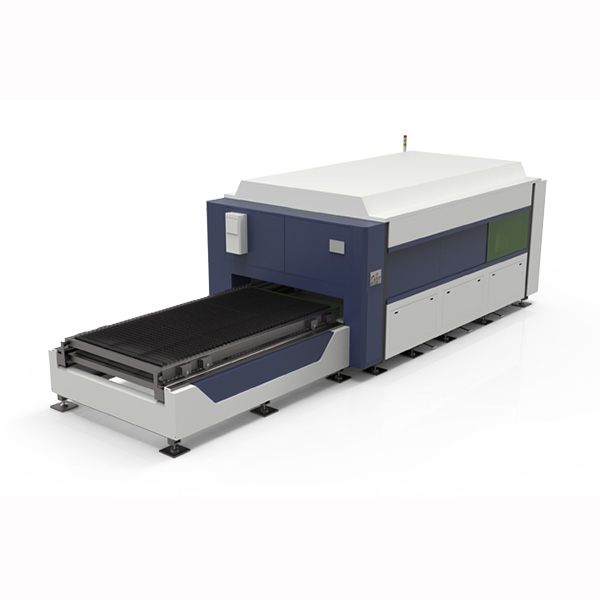

SCNG is a high configuration single table tube and sheet fiber laser cutting machine, which can not only efficiently cut plates, but also cut pipes. This machine adopts Raytools laser head and Yaskawa servo motor, and can be equipped with 1kw-12kw fiber laser to ensure high precision and speed of laser cutting. The vehicle body adopts a heavy-duty structure, which can effectively prevent deformation of the body.

|

Item |

Parameter |

|

Sheet Cutting Range (mm) |

3000×1500/4000×2000/6000×2000 |

|

Pipe diameter (mm) |

120/160/220 |

|

Pipe length (mm) |

3000/6000 |

|

Positioning accuracy (mm) |

±0.05 |

|

Repetitive positioning accuracy (mm) |

±0.01 |

|

Positioning speed (mm/min) |

70 |

|

Maximum acceleration (G) |

1 |

|

Maximum Chuck Rotating Speed (r) |

80-120 |

|

Laser power (W) |

1000-6000 |

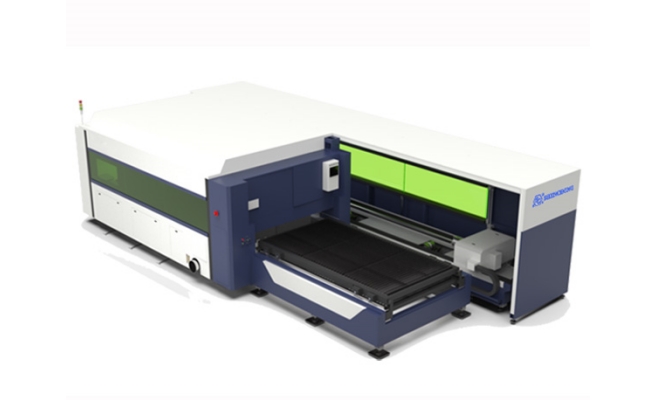

SCMDS fiber laser cutting machine is a tube and sheet fiber laser cutting machine with exchange workbench. It can not only efficiently cut sheets, but also cut pipes.

|

Item |

Parameter |

|

Sheet Cutting Range (mm) |

3000×1500/4000×2000/6000×2000/6000×2300 |

|

/6000×2500/8000×2300/8000×2500 |

|

|

Chuck size (mm) |

120/160/220/280/320/350 |

|

Pipe length (mm) |

3000/6000/7000/9000 |

|

Positioning accuracy (mm) |

±0.03 |

|

Repetitive positioning accuracy (mm) |

±0.01 |

|

Positioning speed (mm/min) |

90 |

|

Maximum acceleration (G) |

1.2 |

|

Maximum Chuck Rotating Speed (r) |

80-120 |

|

Laser power (W) |

1000-6000 |

This device uses Japanese Yaskawa servo motors, Hiwin rails, and French Modoli reducers, ensuring smooth movement while achieving high-precision, high-speed, and low-noise machine operation. This device has strong anti-interference and overload resistance capabilities, ensuring that it can operate for a long time and with high precision.

Pneumatic claws with large and constant clamping force, heavy tube is clamped tightly without slip, cutting accuracy guaranteed. This machine can add a rotating shaft according to customer requirements to achieve pipe cutting function. It can not only cut sheet metal, but also cut and process pipes (square and round pipes).

Adopts the dual-platform automatic exchange system with the platform exchange time of 20-25s, which greatly improves work efficiency.

Adopting high-quality carbon steel welding bed, it is more stable and durable. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.