A punch press is also called as a stamping press. In production, stamping technology is becoming more and more widely used due to its advantages over traditional mechanical processing, such as saving materials and energy, high efficiency, low technical requirements for operators, and the ability to produce products that mechanical processing cannot achieve through various mold applications.

Stamping production is mainly aimed at sheet metal. Through molds, it is possible to produce materials such as cutting, punching, forming, deep drawing, trimming, precision punching, shaping, riveting, and extrusion parts, which are widely used in various fields.

The main difference between a punch and a press is that the holding time of the press is longer than that of a punch. However, the emergence of servo presses in the market has made the definition boundary between presses and presses increasingly blurred. Customers can choose to purchase punches or presses based on their specific product needs.

SC is a leading brand within the punching machine and hydraulic machine fields due to its experience and quality standards. As a professional punch press manufacturer, we produce mechanical press, Pneumatic press, CNC turret punch press and other power presses which are used in different metal-working fabrication areas. We also produce hydraulic press including C frame type, double column hydraulic press, H frame type and four column hydraulic press machine. SC punch press machines are widely used in the field of cutting, stamping, bending, punching, forming, curling, etc.

Hydraulic press machine is a mechanical device that uses liquid static pressure to process products such as metal, plastic, rubber, wood, powder, etc.

SC SHENCHONG has single column C-type hydraulic press, MDY electric double column hydraulic press, Y28 series H-type frame multifunctional universal hydraulic press, Y32 universal four column hydraulic press for sale.

SC SHENCHONG has JH21 series pneumatic punch press machine and YC41 automatic hydraulic punch press machine for sale.

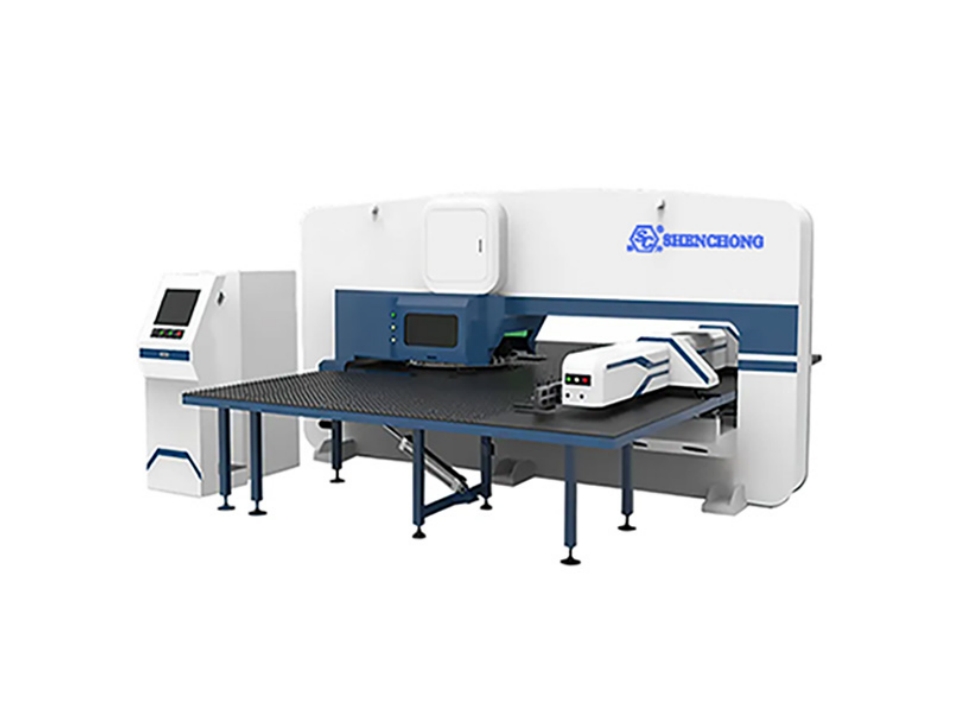

CNC turret punching machine integrates machine, electricity, liquid, and gas, and is a pressure processing equipment that uses turret punching machine molds to perform punching and shallow drawing deep forming on sheet metal.

SC SHENCHONG has CNC fully servo turret punch, CNC hydraulic turret punch, and CNC mechanical turret punch for sale.

Hydraulic ironworker Machine is a machine tool equipment that integrates metal cutting, punching, plate shearing, bending, and other functions. It has the advantages of simple operation, low energy consumption, and low maintenance cost.

Both hydraulic presses and punch presses adopt advanced CNC technology, which can accurately control the machining process and ensure machining accuracy. Especially in industries with high precision requirements, such as automotive parts, aviation parts, etc., the advantages of hydraulic presses and punches are more obvious, which can meet higher precision requirements.

The operation of hydraulic presses and punches is simple, easy to use, and the processing speed is fast, ensuring high efficiency. These advantages make it widely used in industries with mass production, such as automotive manufacturing, electronic product manufacturing, etc.

Hydraulic presses and punch presses have better stability due to the use of high-quality mechanical parts. Throughout the machining process, the equipment has low vibration, low noise, and can ensure consistent machining quality. This makes them more widely used in high demand industries.

Hydraulic presses and punches are not only suitable for the metal processing industry, but also widely used for the processing of non-metallic materials such as plastics and rubber. A wider range of applications means higher economic benefits and the ability to meet the processing requirements of various industries.

A) Different working principles

The working principles of a press and a punch are different. A press is a machine that generates a greater output force than the input force by increasing the force area, and it mainly achieves processing through pressing. A punch press is a machine tool that uses stamping feeding equipment to cut metal stamping parts into the desired shape and size using a punching die. It is mainly achieved through stamping and punching or punching (cutting) to achieve processing.

B) Applicable scope varies

The application range of presses and punches is also different. Press machines are generally suitable for situations with large force and processing area to achieve metal stretching, pressing, embossing printing, and other operations. Punching machines, on the other hand, are suitable for processing thin metal plates and are commonly used for stamping, punching holes, punching grooves, punching angles, and other operations to achieve the machining and manufacturing of components.

C) Different processing objects

The objects processed by presses and punches are also different. A press can process materials with elasticity and shape them by applying pressure to them. This method is suitable for handling shapes such as steel bars, pipes, and pipes. And punching machines are usually suitable for processing parts such as metal plates, metal strips, thin plates, alloy plates, plastic plates, etc.

D) Different operating methods

The operation methods of the press and punch are also different. Press machines usually use heated molds, which form shapes as the temperature increases and the coefficient of thermal expansion increases. The punching machine, on the other hand, uses a cold die to complete the processing according to the shape of the stamping die, and during the processing, it requires the application of impact force or tensile shear force.

In summary, although presses and punches are both machine tools in metal processing, their working principles, scope of application, and processing objects are different. During the processing, it is necessary to choose according to specific circumstances to achieve the best processing effect.

A) Definition of CNC turret punch and ordinary punch

CNC turret punch press is a high-tech equipment that integrates various technologies such as mechanical, electronic, transmission, hydraulic, pneumatic, etc. It utilizes electronic computers for control, as well as variable frequency DC motors and variable form bevel gear transmission, to achieve free tool selection, rotation, input and output functions, and can complete various complex machining operations.

A regular punch is a common mechanical processing equipment that mainly uses punch molds to perform operations such as punching, cutting, and stamping on workpieces. Its processing accuracy is relatively low and requires manual operation.

B) Differences in performance

The CNC turret punch press is controlled by high-performance computers, which can achieve free selection and high-speed rotation of high-speed cutting tools. It can quickly complete various machining operations such as cutting, stamping, bending, etc., and has high machining accuracy and stability.

In contrast, ordinary punching machines use mechanical transmission, which is not very suitable for complex processing operations, and their functional performance is relatively weak, and the processing speed is also relatively slow.

C) Differences in processing efficiency

The CNC turret punch machine has the characteristics of high automation and processing efficiency, which can independently complete a series of processing operations, improving work efficiency and production efficiency. Ordinary punching machines require a longer period of manual operation, resulting in relatively low production efficiency. They are not as efficient as CNC turret punching machines in large-scale and complex processing operations,

D) Differences in operation

The operation of CNC turret punching machines is relatively complex and requires high professional skills to operate. Using CNC programming for operation also requires a certain level of computer knowledge.

The operation of ordinary punching machines is relatively simple, and it does not require a high level of technical expertise and professional knowledge like CNC turret punching machines. It only requires mechanical transmission and manual operation.

E) Price differences

Due to the more complex technical structure and functional advantages of CNC turret punching machines, their prices are higher and require more capital investment to purchase, while ordinary punching machines are relatively cheaper and generally suitable for small enterprises or individual factories starting their own businesses.

In summary, the differences between CNC turret punching machines and ordinary punching machines are mainly reflected in performance, processing efficiency, operation mode, and price. If complex and efficient machining operations are required, choosing a CNC turret punch machine will be more suitable; For some simple processing operations, choosing a regular punch can be more economical and practical.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.