Automatic sheet metal storage system also called as intelligent sheet metal storage tower, is a material warehouse that computer controlled automatically feeding, unloading, storage the sheet metal plate, and can connect with other machines to reach the unmanned operation.

In the production workshop of sheet metal processing, there is a common phenomenon that the raw materials of the sheet metal are mixed together, or frequent loading/unloading, sheet positioning, transportation and storage operations are required during batch cutting/bending of metal sheets, which has pain points such as high labor costs, low production efficiency, inability to guarantee processing accuracy, and high safety hazards.

SC SHENCHONG automatic sheet metal storage system can perfectly solve all these problems.

According to different factory layout and metal storage requirement, SC Shenchong provide different intelligent metal storage system series:

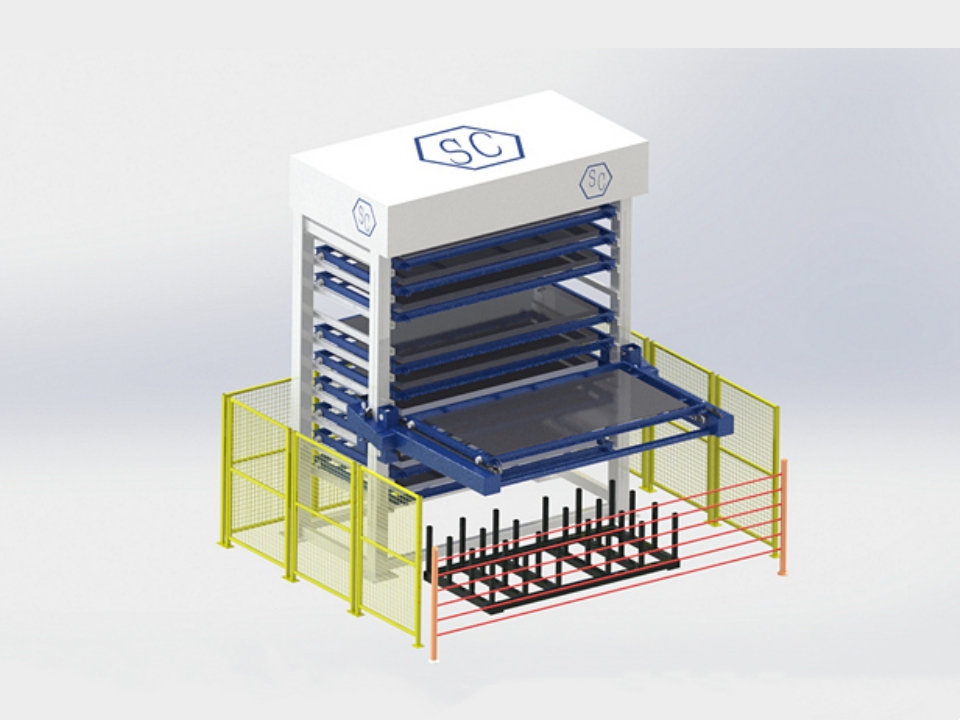

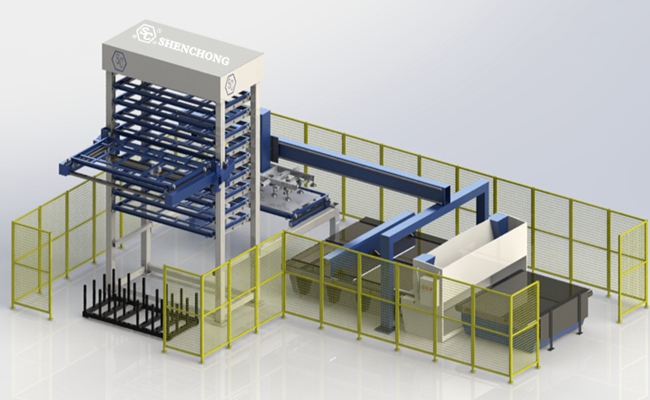

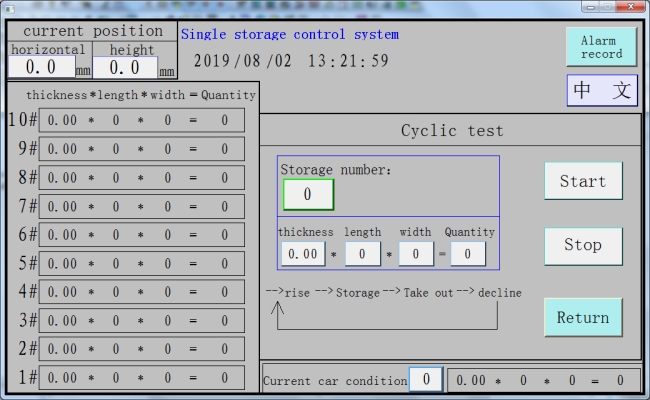

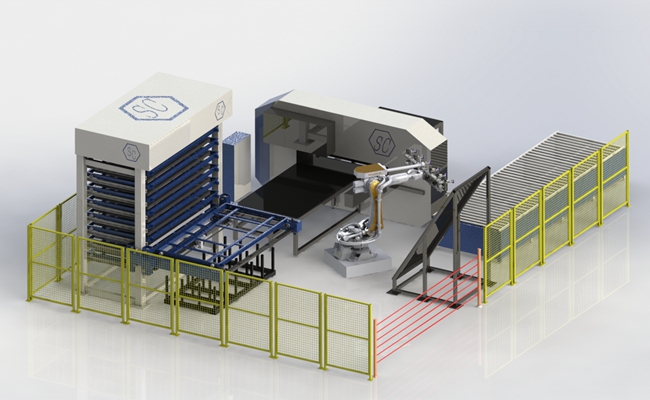

SHENCHONG single intelligent storage system has multiple layers for classifying and storing sheets. Controlled by a computer, intelligently selecting each layer of sheet plate, and automatically conveying the sheet during the production process.

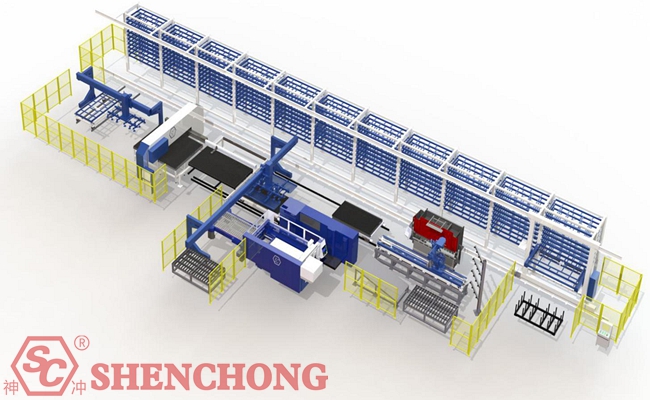

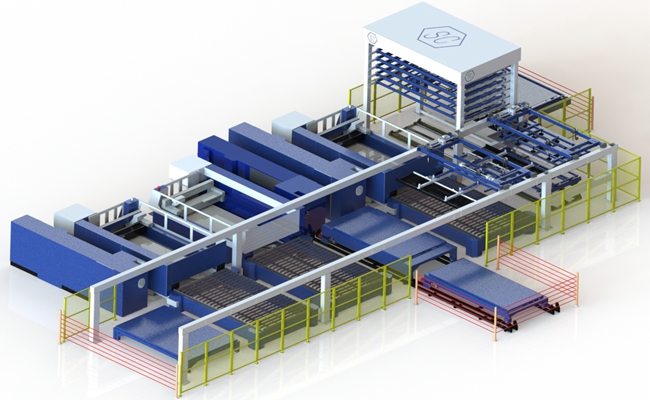

The combined rows intelligent storage system can store a large amount of raw materials, achieving true unmanned sheet material storage for large factories. Connect automated production lines such as laser cutting machines, automatic stamping centers, robot automatic bending machines, rolling centers, various forming lines, automatic welding production lines, and spraying lines as unmanned factories.

|

Model |

SC-2513 |

SC-3015 |

SC-4020 |

SC-6020 |

|

Rated Load (t) |

3-5 |

3-5 |

3-5 |

3-5 |

|

Sheet Size (mm) |

1250*2500 |

1500*3000 |

2000*4000 |

2000*6000 |

|

Number of Storage Layers |

10 |

10 |

10 |

10 |

|

Total Height (mm) |

4800 |

5090 |

5590 |

5800 |

|

Floor Area (mm) |

3500*3600 |

4100*4200 |

5200*5200 |

7500*5800 |

|

Single Layer Height (mm) |

250 |

250 |

250 |

250 |

|

Increase Speed (M/min) |

8-12 |

8-12 |

8-12 |

8-12 |

|

Feeding Rate (M/min) |

8-12 |

8-12 |

8-12 |

8-12 |

|

Power (KW) |

12-20 |

12-20 |

12-25 |

12-25 |

Cantilever Type Sheet Metal Storage System

The cantilever type material storage relies on the cantilever to complete the loading and unloading, with a simple structure and beautiful appearance

In less occupied areas, the cantilever material storage system can directly retrieve materials.

Gantry Truss Type Sheet Metal Storage System

The gantry truss type material storage relies on the upper and lower transportation of plate materials by the truss for easy side discharge into the warehouse

The combined material storage is a gantry type material storage, which does not interfere with each other

The gantry type cannot be loaded with a crane

When the material is fed, the forklift or the vehicle is used with the loading positioning table to place the plate at the origin position of the tray.

The hoist automatically sends the plates to the empty position of the tower, and the system automatically records the plate information.

When a plate of a certain specification is required for production, the hoist automatically takes the material out of the corresponding location.

The automation of material loading and unloading has been widely applied in the field of planar laser cutting, and there are many different solutions. In contrast, the laser pipe cutting system with vertical profile material storage system, which can automatically process and storage profiles and pipes, achieve unmanned operation and switch production, has only been achieved in the past few years.

Adopting a double column lifting mechanism, the motor is driven by multiple rows of chains to lift the feeding tray and the board. The pushing mechanism on the lifting machine hooks one side of the feeding tray to achieve the entry and exit of the board. The CNC system adopts laser scanning for closed-loop positioning, synchronously eliminating the extension size of the chain, and has the functions of precise positioning, stable operation, and fast and flexible operation.

The control system is designed reasonably, operated simply and conveniently, has a beautiful and elegant appearance, and has advanced intelligent warehouse management and automatic loading and unloading functions. Adopting the most advanced and mature control systems and technologies, it has high precision, high reliability, and high response speed.

The sheet metal intelligent storage warehouse is used to classify and store various types of metal sheets, and control the entry and exit of sheets and select each layer of sheets through a computer. The metal automatic storage system can serve as an independent storage unit or be connected to the enterprise’s MES system, providing raw materials and storing finished materials for laser cutting machines, robotic press brake, automatic turret punch press, automatic panel bender and other equipment. This depends on the customer’s processing steps.

As a professional automatic metal storage system factory, SC SHENCHONG has already produced and sold various types of intelligent metal storage tower to different countries around the world. We have a large number of customer cases and have full experience to design the storage system based on customers’ requirements and install and adjust the system oversea.

Since we are automatic metal storage system factory, we can offer factory direct price of the storage system. We do not charge the automatic sheet metal storage system design fees, and we can provide you with customized proposal at the first time.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.