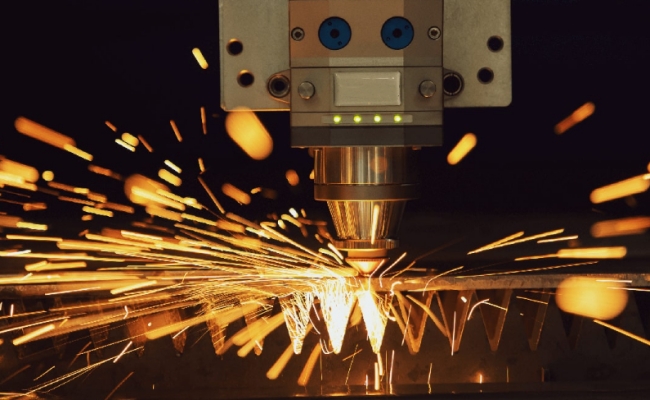

Metal sheet fiber laser cutting machine, as the name suggests, is a laser cutting equipment used for metal sheets. Due to the high hardness and good thermal conductivity of metal materials, laser cutting technology is more suitable for processing metal materials.

The application range of metal sheet laser cutting machine:

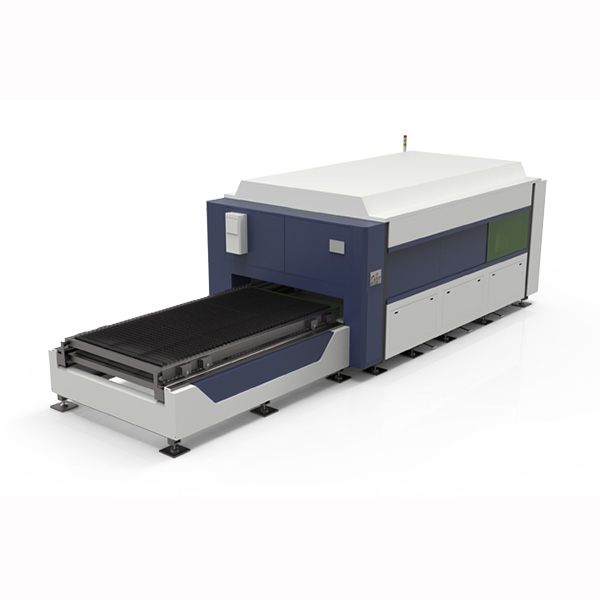

SCM serie sheet fiber laser cutting machine with single table has advantages of affordable price, simple design, high dynamic performance, and space saving.

SCM fiber laser cutting machine adopts a Raytools laser head and Yaskawa servo motor and can be equipped with a 1kw-6kw fiber laser to ensure high precision and high speed of laser cutting. SHENCHONG SCM fiber laser cutting machine can choose a variety of cutting areas: 1500mm*3000mm, 1500mm*4000m, 2000mm*4000mmmm, 1500*6000mm, 2000*6000mm and 2500mm*6000mm, and can also customize the cutting area according to customer requirements.

After years of mature use and continuous optimization and improvement in the field of laser cutting, SHENCHONG fiber laser cutting machine has high performance, reliability, and user-friendly and convenient operation. Adopting a servo motor dual drive precision reducer and gear rack structure, ensuring the high-speed, high-precision and reliable operation of the equipment.

|

Model |

SCM 3015 |

SCM 4015 |

SCM 6015 |

SCM 4020 |

SMC 6020 |

SMC 6025 |

|

Power |

1000w~6000w |

|||||

|

Cutting Range |

3050*1530mm |

4050*1530mm |

6050*1530mm |

4050*2030mm |

6050*2030mm |

6050*2530mm |

|

Max. Moving Speed |

80m/min |

80m/min |

80m/min |

80m/min |

80m/min |

80m/min |

|

Position Precision |

±0.01mm |

|||||

|

Repeat Position Precision |

±0.03mm |

|||||

Single table fiber laser cutting machine canload/unload sheet metal plate during cutting which improves the processing efficiency.

LIGHTNING PERFORATION TECHNOLOGY ADVANTAGES:

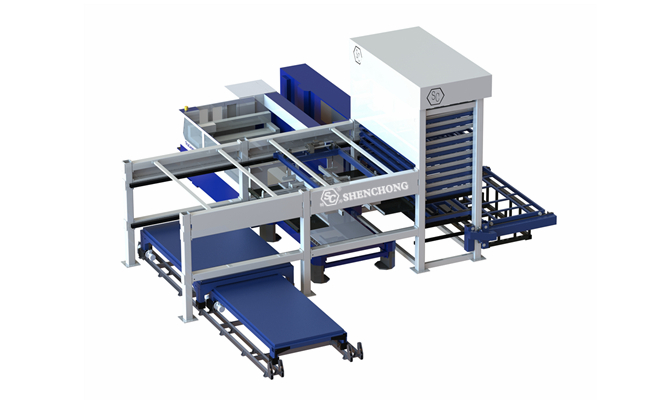

SC Shenchong double change table sheet fiber laser cutting machine is a laser cutting machine with an exchange workbench and a fully enclosed protective cover. This model not only has an exchange worktable, but is also equipped with a fully enclosed laser protective cover and a dust recovery and purification system. It can not only help users reduce downtime caused by precision machining of workpieces, but also reduce light pollution and smoke pollution caused by laser cutting during equipment operation. The body adopts a heavy-duty structure, which can effectively prevent deformation of the body.

SHENCHONG has 10 years of experience in laser cutting machine production and is committed to providing professional laser solutions to customers worldwide. As a professional fiber laser cutting machine manufacturer, we have designed sheet fiber laser cutting machines with different powers and models to meet the needs of different customers. The SC sheet fiber laser cutting machine adopts strict assembly technology and world-class brand parts, ensuring high cutting accuracy and strong cutting ability, thereby maximizing the productivity and profitability of sheet metal manufacturers.

|

Model |

SCDM 3015 |

SCDM 6015 |

SCDM 4020 |

SCDM 6020 |

SCDM 6025 |

SCDM 12025 |

|

Power |

1000w~30000w |

|||||

|

Cutting Range |

3050*1530mm |

6050*1530mm |

4050*2030mm |

6050*2030mm |

6050*2530mm |

12100*2530mm |

|

Max. Moving Speed |

100m/min |

100m/min |

120m/min |

120m/min |

120m/min |

120m/min |

|

Position Precision |

±0.03mm |

|||||

|

Repeat Position Precision |

±0.02mm |

|||||

All-aluminum cast beam, long life, high precision and good stability. The beam is manufactured according to the aerospace standard. Compared with the steel beam, the weight is greatly reduced, the load of the servo motor is reduced, and the inertia is reduced. After aging treatment, the beam has the characteristics of lightweight, high strength, and high running precision. The lightweight beam can ensure the fast operation of the equipment, improve the processing efficiency and ensure the processing quality at the same time.

The internal structure of the bed is welded by multiple rectangular tubes, and there are reinforced rectangular tubes inside the bed to enhance the strength and stability of the body. The solid body structure not only increases the stability of the guide rail but also effectively prevents the deformation of the body. The bed is annealed, stronger not easy to deform, long service life.

We adopt Raycus new fiber laser with high photoelectric conversion efficiency and stable optical quality. Fiber lasers have reliable performance and low overall cost, which can help end users improve productivity while reducing costs.

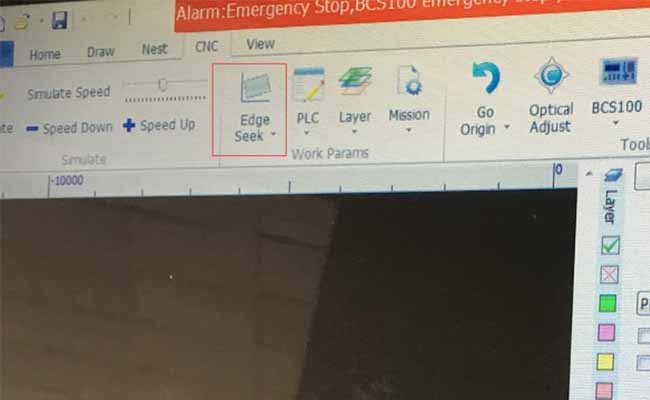

CypCut plane cutting software is a set of software specially developed for the deep customization of the laser cutting industry,easy to use, rich in functions, suitable for various processing occasions.

Edge Finding Aid

Dual-drive deviation self-correcting two-stage capacitive edge seeking.

Professional laser cutting machine CNC control system, computer operation, can guarantee the cutting quality, make the cutting work more convenient, and the operation simpler.

Accuracy: realizes closed-loop control of position, speed and torque; overcomes the problem of stepping motor out of step.

Rotating speed: high speed performance, general rated speed can reach 2000~3000 rpm.

The laser head is made of high quality materials in accordance with advanced technology. It is strcng and curable it can achieve ‘onine’ measure ment during the production process, and the measurement is accurate and rapid.

The temperature of the refrigeration unit is shown by a digital meter.

When the water temperature exceeds the specified temperature, the refrigeration unit will automatically cool. When the water temperature is lowered than the specified temperature, the refrigeration unit will automatically stop cooling and have a electric heating function.

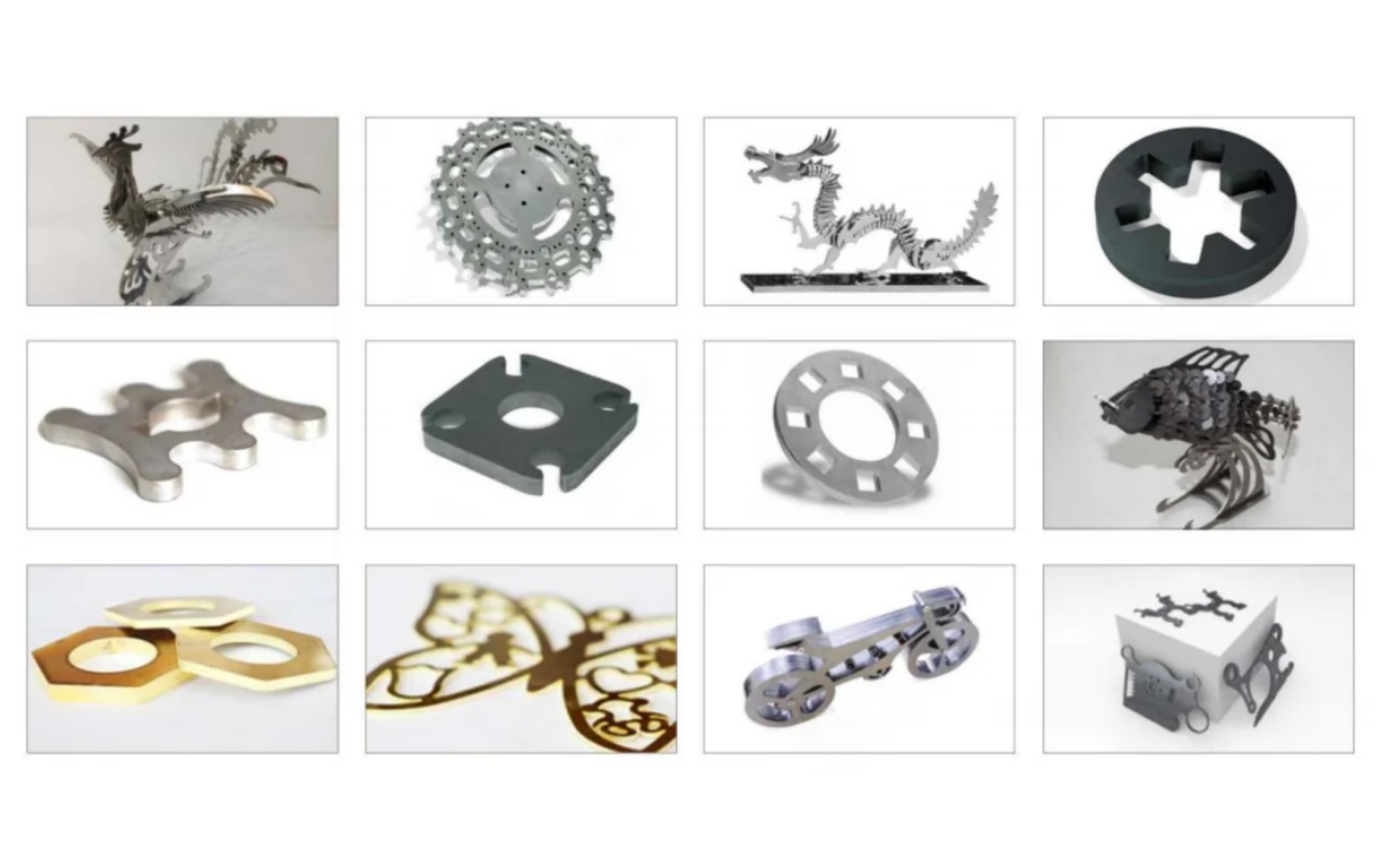

The SC SHENCHONG sheet fiber laser cutting machine can cut all types of metals, from mild steel to stainless steel and non-ferrous metals. But some highly reflective metals, such as aluminum and copper, are more difficult to cut. The maximum thickness of metal that can be cut by laser is determined by the laser source. In theory, the higher the laser power, the greater the thickness that can be cut. In addition, the professional knowledge of machine operators can also affect the thickness of laser cutting.

Before assembly: Check and inspect whether the processing form and positional tolerance of the crossbeam are within the design range to ensure equipment quality.

During the assembly process: installation inspection and fixation of guide rails and racks.

Assembly completion inspection: By combining different optical components with relevant software, the dynamic performance of CNC machine tools can be tested.

Automatic loading and unloading of cantilever materials (automatic loading and unloading for laser cutting machines) works in collaboration with various types of laser cutting machines to achieve automatic loading and unloading of metal sheets, automatic separation of finished products and waste materials, and more economical and safe production. SC Shenchong has a research and development team that designs and produces laser cutting machine automation systems to meet customers’ automatic cutting requirements.

Diference 1: The difference in cutting thickness

The plasma cutting machine is a kind of thermal cutting equipment, which is more suitable for more than 6mm thickness and with low precision requirement. In theory, the maximum thickness of a plasma laser cutting machine can reach hundreds of mm, but the optimal cutting range is about 80mm. Disadvantages of plasma cutting: It is not suitable for cutting below 3mm metal sheets, the slit is wide and the precision is poor, the cutting surface with poor perpendicular when cutting 5mm or more than 5mm thickness plate. Sheet fiber laser cutting machine can be the substitution of the plasma cutting machine.

Diference 2: The difference in cutting quality

The cutting principle of the plasma cutting machine is to use high temperature plasma arc heat to melt the metal at the cutting part of the workpiece, and simultaneously blow away the molten metal with a high-speed air flow to form a narrow slit; the plasma cutting machine can cutting stainless steel, iron, aluminum, various metal materials.

Through the high-speed airflow coaxial with the beam to melt the material, the thermal cutting method of the metal sheet is opened. In metal processing, the main processing speed is fast, so that the cut surface is smooth; no burrs; high cutting accuracy, no need for secondary time-consuming processing and other advantages, before the user buys the laser cutting machine equipment, the first thing to consider is to buy a certain kind of power equipment, the biggest factor determining the power depends on the thickness of the processing material, the thicker the plate, the more difficult it is to cut, and the more power required.

For the laser cutting machine that is continuously developed and designed, well-known laser cutting machine brands must be selected for its low power. Medium-power and high-power laser cutting machine equipment not only requires high quality of the equipment itself, but also the cutting process parameters are technical issues, so medium power Manufacturers of low power are far lower than those of low power.

Fiber laser cutting machines have a broad range of applications due to their high precision, flexibility, and fast processing speeds. But where do they truly shine? Which materials can they effectively work with? Let’s discuss in detail.

Firstly, let’s focus on the materials. Fiber laser cutting machines are best suited for cutting various metals, particularly reflective ones. This includes:

Now, let’s delve into the various applications where fiber laser cutting machines are most effective:

In conclusion, fiber laser cutting machines are well suited for a wide array of materials and applications. Their versatility and efficiency make them a standout choice for industries requiring precision metal cutting.

The cost of a laser cutting machine can vary widely based on a number of factors, such as the size of the machine, cutting capabilities, brand, and level of automation, among others. Generally speaking, the price of a small entry-level fiber laser cutting machine is between US$15,000 and US$45,000. Affordable fiber laser cutting machines for small businesses, hobbyists, or educational institutions that need basic cutting capabilities.

Please note that because the price of the fiber laser cutting machine will be subject to market fluctuations, this price is only a reference price. If you want to get the detailed price of the fiber laser cutting machine, you can contact us. Our business staff will provide you with affordable fiber laser cutting machine quotations.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.