Table of Contents

This is a SC 20mm sheet metal bending machine for sale, which is used to bend ordinary iron plates with a thickness of about 20mm. The SC 20mm metal plate bending machine is a heavy-duty CNC hydraulic press brake equipment specially used for processing metal plates with a thickness of up to 20mm.

It is widely used in steel components, shipbuilding, bridges, energy equipment, engineering machinery and other industries. It has the characteristics of high tonnage, large workbench width, strong structural rigidity and CNC precision control.

1. Equipment Overview: 20mm Sheet Metal Bending Machine For Sale

The 20mm sheet metal bending machine is a medium-to-large bending equipment, mainly suitable for precision bending of materials such as carbon steel, stainless steel, and aluminum alloy. Its design must take into account rigidity, precision and ease of operation.

- Type: CNC WEK electro-hydraulic synchronization series

- Applicable materials: carbon steel, stainless steel, aluminum alloy, copper plate and other metal plates with a thickness of ≤20mm

- Bending capacity: 20mm thick plates can be bent at 90 degrees and multiple angles, and the selection is based on the bending length and material strength.

Main configuration parameter table (typical) of 20mm sheet metal bending machine:

Item | Typical parameters |

Nominal pressure | 400 tons ~ 800 tons (depending on bending width) |

Bending length | 4000mm ~ 8000mm |

Maximum plate thickness | 20mm (Q235) |

Stroke | 200~300mm |

Opening height | 400mm ~ 600mm |

Control system | ESA, Delem, Cybelec and other CNC systems |

Synchronization mode | Electro-hydraulic servo synchronization (Y1/Y2) |

Number of supported axes | 4+1 axis, 6+1 axis, 8+1 axis etc. |

Back gauge stroke | 600~1000mm, multi-axis control possible |

2. Main components and structures of 20mm sheet metal bending machine

- Frame: integrally welded or cast steel structure, bearing the weight of the whole machine, ensuring long-term use without deformation.

- Slider (upper die): the core component to complete the bending action, driven up and down by a hydraulic cylinder or motor.

- Workbench (lower die): supports the plate and the lower die, usually equipped with a mold quick change structure.

- Back gauge system: used to position the plate to ensure the bending size accuracy; high-end equipment is equipped with servo-controlled multi-axis gauges.

- Control system: programmable computer numerical control (CNC), realizing multi-stage bending, angle compensation, program storage and other functions.

3. Key structural features

- High-strength frame structure: the whole machine is welded with Q345 steel plate, which is aging treated or tempered to ensure rigidity and durability.

- Electro-hydraulic servo control system: synchronous control is achieved through high-precision proportional servo valve and encoder, and the bending angle consistency is good.

- Heavy-duty cylinder system: large-diameter hydraulic cylinder is used to ensure sufficient downward pressure.

- V-groove of the lower die is adjustable or replaceable: to meet the processing requirements of different plate thicknesses and bending radii.

- Eequipped withfront support device or independent bending follwers: convenient for positioning and handling when processing large plates.

- Laser safety protection system (optional): such as DSP or MSD system, to improve operational safety.

4. Application scenarios

- Steel structure processing plant

- Shipbuilding and offshore equipment manufacturing

- Engineering machinery (buckets, brackets, etc.)

- Electric power equipment (transformer housing, etc.)

- High-end metal forming and processing companies

5. Applicable materials and thickness

Material | Bend thickness (reference) | Notes |

Q235 carbon steel | 20mm (full length) | Bending length ≤3000~4000mm |

304 stainless steel | 16~18mm | Tonnage needs to be increased by 10~20% |

Aluminum plate | 25~30mm | Depending on the strength of the material |

6. 20mm metal plate bending case analysis

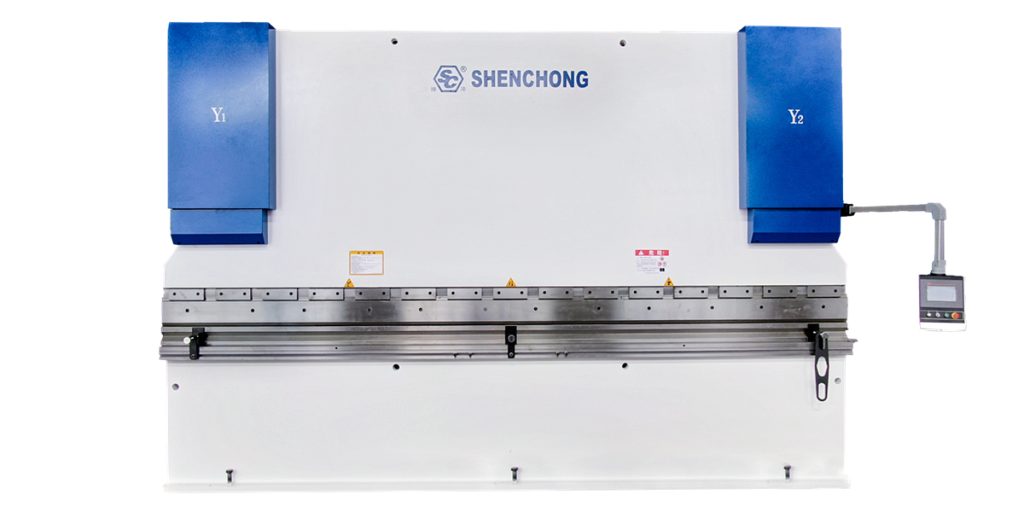

Take SC 400ton 6000mm CNC hydraulic press brake machine in the picture as an example for analysis.

Bending capacity estimation (Q235 ordinary carbon steel):

Plate thickness | Bendable plate length |

12mm | ≈6000mm (full length) |

14mm | ≈5000mm |

16mm | ≈4200mm |

18mm | ≈3700mm |

20mm | ≈3200mm |

22mm | ≈2800mm |

25mm | ≈2400mm |

Note:

- The valuesin the table are based on the general experience that the lower die V groove is 8 to 10 times the plate thickness.

- When bending stainless steel (such as 304), due to its higher strength, the thickness in the table should be estimated by 20%.

- When the bending width becomes narrower, the thickness can be folded thicker; when the width becomes wider, the thickness can be folded thinner.

Analysis results of the example of a 400ton 6000mm CNC hydraulic bending machine:

- When bending a 12mm Q235 steel plate, a 400ton 6000mm press brake machine can be used to bend a full 6 meters in length at one time;

- When bending a 20mm steel plate, it can only be folded to about 3.2 meters in length, and the tonnage is insufficient for longer lengths.

7. Selection Recommendations

When choosing a press brake bending machine suitable for 20mm thick plate bending, you should focus on the following points:

- Bending length: The length of the plate determines the size of the bending machine worktable

- Plate material: Stainless steel requires greater pressure, and it is recommended to choose a high tonnage

- Production requirements: For large-scale, high-precision production, it is recommended to choose a servo CNC press brake machine

- Budget: Ordinary hydraulic press brake machines are suitable for medium and low budget requirements

If you have specific processing requirements or want to obtain more detailed product information and quotations, please contact us for a customized solution.