Table of Contents

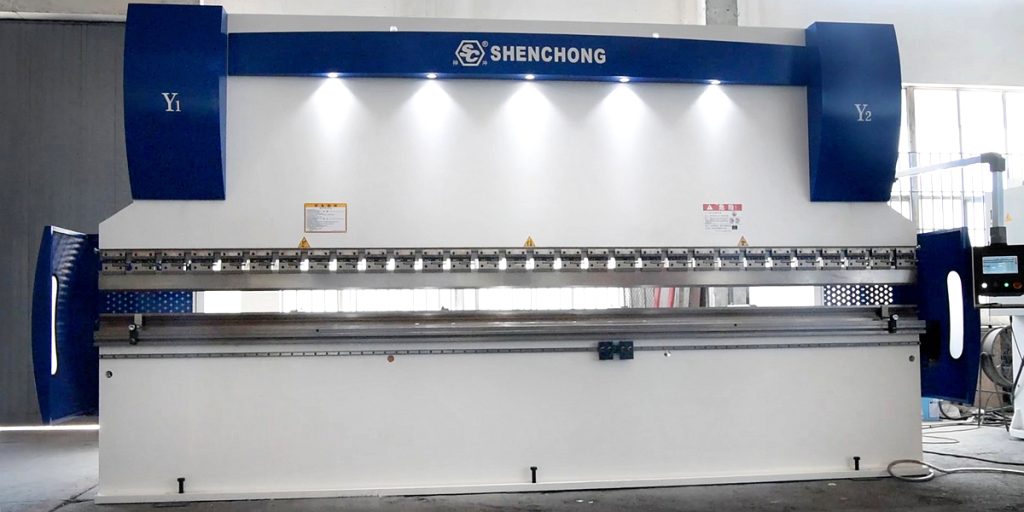

4mm metal plate bending machine is a special CNC equipment used to process metal plates with a thickness of 4mm. Through the cooperation of the upper die and the lower die, the bending force is applied to the plate to achieve the required angle or shape of bending.

1. Core technical parameters (typical models) of 4mm metal plate bending machines

The 4mm metal sheet CNC hydraulic press brake is an automated bending equipment specially used for bending metal plates with a thickness of 4mm (such as Q235 carbon steel, stainless steel, aluminum alloy, etc.). The equipment adopts a hydraulic drive system and realizes multi-axis linkage control through a CNC system, which can complete various bending tasks with high precision.

Technical parameter table (typical models):

Item | Parameter range |

Maximum plate thickness | 4mm (carbon steel) |

Maximum bending length | 2500mm, 3200mm, 4000mm, 6000mm (optional) |

Nominal pressure (tonnage) | 63T, 100T, 125T, 160T, 200T, 250T (depending on the length) |

Control system | ESA S630/S640, Delem DA-53T/DA-66T, EL15T/19T, etc. |

Synchronization method | Electro-hydraulic servo synchronization (Y1, Y2) |

Number of back gauge axes | X-axis (front and back), R-axis (up and down), support multi-axis expansion (X1/X2/R1/R2/Z axis) |

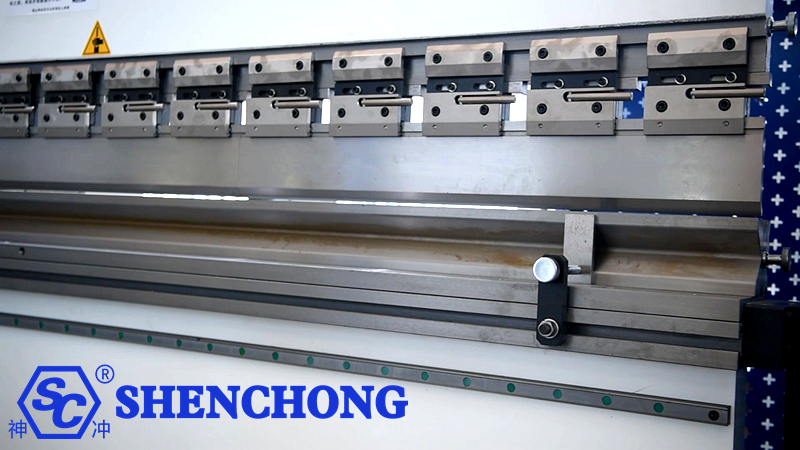

Repeat positioning accuracy | ±0.01mm (depending on system configuration) |

Bending angle accuracy | Within ±0.5° |

2. Structural composition

- Frame system: welded integral structure, tempered to eliminate internal stress

- Hydraulic system: double cylinder upper pressure hydraulic system, stable pressure

- CNC system: control slide (Y1/Y2), back gauge (X/R equiaxes)

- Mold system: upper die + V-shaped lower die (customizable), quick clamp

- Back gauge system: servo motor drive, suitable for various bending depths

- Safety devices: laser protection (MSD/DSP), emergency stop button, front guardrail, etc.

3. Performance advantages

- High precision: CNC system monitors position and pressure in real time, with a repeatability of up to ±01mm

- Easy operation: graphical human-machine interface, program can be stored and called

- Energy saving and noise reduction: electro-hydraulic servo system can intelligently adjust the cylinder action to reduce energy consumption

- Flexible expansion: supports 4+1 axis, 6+1 axis and other multi-axis control, adapting to complex bending

- Strong automation: optional manipulator, material warehouse, automatic loading and unloading platform, to achieve automatic production line docking

4. Scope of application

- Ventilation ducts, chassis cabinets, control boxes

- Industrial equipment shell processing

- Electrical and electronic control, communication equipment sheet metal

- Stainless steel decorative panels, aluminum alloy components

- Small batch automotive parts, home appliance sheet metal processing

5. Applicable materials and thickness adjustment table

Material Type | Bending capacity description |

Q235 Carbon Steel | Continuous bending below 4mm |

304 Stainless Steel | Recommended not to exceed 3mm (higher strength) |

Aluminum Alloy | Above 4mm (lower strength than carbon steel) |

Galvanized Sheet | 4mm |

Different materials have different bending coefficients, and stainless steel requires a higher tonnage.

6. 4mm Metal Plate Bending Case Analysis

We take the SC 200ton 6000mm CNC hydraulic press brake as an example to analyze the bending force capacity. How thick a 200ton 6000mm CNC hydraulic press brake (i.e., bending force of 200 tons and bending length of 6000mm) can bend mainly depends on the material of the plate and the size of the bending die (especially the V-groove of the lower die opening). The following is a reference data based on ordinary Q235 carbon steel.

Reference value (Q235 carbon steel, bending die V-groove is 8 times the plate thickness):

Plate thickness (mm) | Bending length (maximum, unit: mm) |

3mm | 6000mm (full length bending) |

4mm | 6000mm |

5mm | About 5500mm |

6mm | About 4500mm |

8mm | About 3500mm |

10mm | About 2500mm |

Note:

Different materials have different bending capabilities:

Stainless steel (such as 304) is harder than carbon steel, and the bending capacity needs to be reduced by 20%.

Aluminum is softer than carbon steel and can be bent longer.

The mold has a great influence:

Using different lower mold openings (such as 6T, 8T, 10T, 12T) will change the required tonnage, which in turn affects the thickness of the bendable plate.

Stronger local bending ability:

If it is not a whole 6-meter plate, but only partially bent in the middle (for example, within 2 meters), it can be bent thicker.

200 tons 6000mm CNC hydraulic bending machine bends Q235 carbon steel plate, and the maximum thickness of the plate can be bent is about 4mm. If it is only bent within 3 meters, it can be bent 5-6mm plate.

7. Typical configuration examples of SC 4mm metal plate bending machine for sale

Model | Nominal pressure | Bending length | Control system | Axis configuration |

WEK-63T/2500 | 63 tons | 2500mm | ESA S630 | 4+1 axis |

WSK-100T/3200 | 100 tons | 3200mm | EL15T | 4+1 axis |

WDK-170T/4000 | 170 tons | 4000mm | ESA S640 | 6+1 axis |

WSK-200T/6000 | 200 tons | 6000mm | EL19T | 6+1 axis |

If you can tell me the specific type of plate to be bent (such as Q235, 304 stainless steel, aluminum alloy) and the actual bending length (full length of 6 meters or in sections), we can give more accurate selection suggestions.