Table of Contents

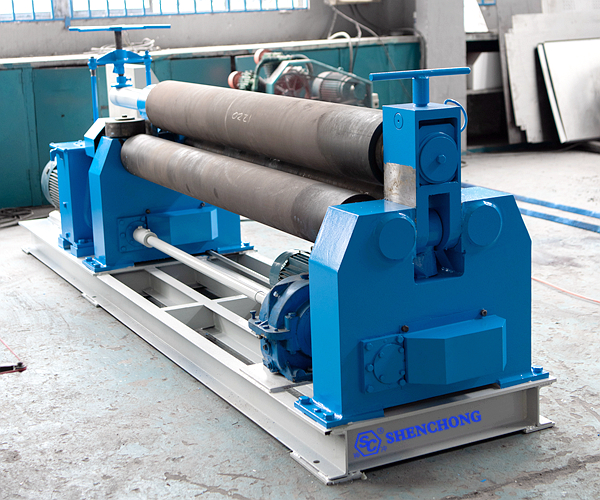

This Russia Three Roller Plate Bending Machine is a mechanical symmetrical three-roller plate rolling machine W11-12X2000MM, which is used to roll metal sheets into round or curved workpieces.

1. Main technical parameters of Russia three roller plate bending machine (with cone rolling device)

Parameters | Description |

Maximum roll thickness | 12 mm (Q235 steel, yield strength 245 MPa) |

Maximum roll width | 2000 mm |

Minimum roll diameter | 550 mm (under full load) |

Upper roll diameter | 240 mm |

Lower roll diameter | 200 mm |

Lower roll center distance | 300 mm |

Rolling speed | Approx. 4.5 m/min |

Main motor power | 11 kW |

Rolling cone device | Optional, suitable for workpieces with a taper of ≤15° |

Upper roll displacement display | Digital display optional |

2. Structure and working principle of the 3 roller mechanical plate rolling machine

- Symmetrical three-roller structure:the upper roller is centered and can move up and down, the two lower rollers are fixed and driven to rotate by the motor, and the plate is rolled by the compression and friction between the upper and lower rollers.

- Mechanical drive system: the main motor drives the lower roller to rotate through the reducer to achieve the rolling of the plate.

- Upper roller lifting mechanism:the lifting and lowering of the upper roller is controlled by a mechanical screw or hydraulic system to adjust the rolling pressure and the curvature of the plate.

- Conical rolling function:the relative position between the upper roller and the lower roller is adjusted by the cone rolling device to achieve the rolling of the conical workpiece.

3. Introduction to the function of the cone rolling device

The cone rolling device adjusts the relative position between the upper roller and the lower roller to make the plate form a cone during the rolling process. The device usually includes an adjustable support mechanism and a guide device to meet the rolling requirements of different tapers.

The cone rolling device is suitable for workpieces with a taper less than 15°, and the thickness and width of the rolled plate should be less than 1/3 of the full load. This device is an optional accessory and needs to be purchased separately according to actual needs.

4. Applicable scenarios and advantages

- Applicable materials: medium-thickness metal plates such as carbon steel, stainless steel, and aluminum alloy.

- Application areas: pressure vessels, boiler manufacturing, wind power towers, chemical equipment, machinery manufacturing, etc.

SC Russia three roller plate bending machine advantages and characteristics:

- Simple structure, easy operation, and low maintenance cost.

- Equipped with a rolling cone device, it can meet a variety of rolling needs.

- Suitable for small and medium-sized batch production, high cost performance.

SC Machinery Russia W11-12×2000mm mechanical symmetrical 3-roller plate rolling machine is a classic sheet metal forming equipment, suitable for rolling medium-thick steel plates into cylindrical or conical workpieces. Equipped with a cone rolling device, it can efficiently realize the processing of conical cylinders and is widely used in pressure vessels, boiler manufacturing, wind power towers, chemical equipment and other fields.

If you need to know more about the price, delivery time or other technical details of this model of plate rolling machine, please contact us for consultation!