Table of Contents

Improving the shearing machine working efficiency is of great practical significance, and is related to the production capacity, cost control, delivery cycle, product quality and other key dimensions of the enterprise. How to effectively improve the shearing machine efficiency? The key to improving the working efficiency of metal plate shearing machines lies in: equipment performance, process flow, personnel operation, automation and management system, etc.

1. Analysis of factors affecting shearing machine working efficiency

Analysis of factors affecting shearing machine working efficiency is a key step in improving production capacity and optimizing processes. The following is a detailed summary of the main factors affecting shearing machine efficiency from multiple dimensions to help you identify bottlenecks and develop improvement measures.

1) Equipment factors

Factors | Impact description |

Shearing machine type | Hydraulic shearing machines cut more smoothly than mechanical shearing machines, and CNC shearing machines have a higher degree of automation, which is suitable for high-precision and high-efficiency production. |

Equipment performance status | Old or poorly maintained equipment will reduce the shearing speed, increase downtime, and affect overall production capacity. |

Blade quality and wear degree | Blunt knives will lead to poor shearing, increased rework rate, and even failure to shear normally in severe cases. |

Whether the blade gap adjustment is reasonable | Gaps that are too large or too small will affect the shearing quality and speed, especially when cutting materials of different thicknesses. |

Automation supporting equipment | The lack of automatic feeding, stacking or waste collection devices will increase manual intervention and reduce efficiency. |

2) Operator factors

Factors | Impact Description |

Operation proficiency | Experienced workers can reduce the time for setting, positioning and material change; novices are prone to improper operation, increasing the error rate and unplanned downtime. |

Safety awareness and standardized operation | Non-standard operation may cause failures or even safety accidents, affecting the overall operation efficiency. |

Tool and material change time control | Unskilled operation process or unreasonable operation table layout will prolong the auxiliary time. |

3) Material factors

Factors | Impact Description |

Material type (stainless steel, aluminum, carbon steel, etc.) | Different materials have different shearing difficulties. High-strength materials have slow shearing speeds and wear quickly. |

Plate thickness and width | Shearing thick plates requires higher shearing forces, which reduces the equipment’s operating rhythm; feeding wide plates is also more time-consuming. |

Raw material quality issues | Uneven or oily plates may cause sliding and misalignment, increasing rework rates and operating difficulties. |

4) Process and scheduling factors

Factors | Impact description |

Shearing sequence and layout optimization | Reasonable layout reduces process conversion and improves material utilization; unreasonable layout increases waste and switching time. |

Batch size | Small batches with multiple varieties will increase mold/program change time, while large batches are suitable for continuous and efficient processing. |

Shearing error control requirements | If the precision requirement is high, the shearing speed needs to be reduced, the adjustment frequency increases, and the efficiency is affected. |

5) Management and environmental factors

Factors | Impact description |

Reasonableness of production plan | Chaotic scheduling and frequent material changes will cause the equipment to idle and frequently adjust, reducing effective operation time. |

Maintenance management system | Whether regular maintenance and preventive maintenance are implemented determines whether the equipment operates stably. |

Worksite layout | Unreasonable feeding/discharging paths and crowded space will increase manual handling time. |

Production record and feedback mechanism | Decisions without data support may not be able to find bottlenecks, and efficiency improvements are difficult to quantify. |

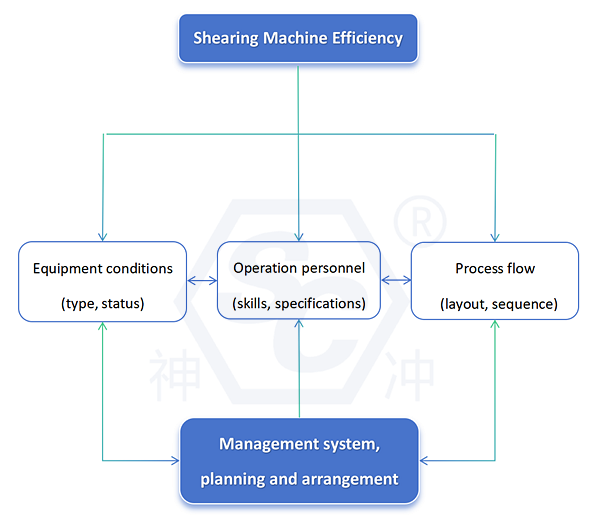

Influencing factors relationship diagram (brief):

2. How to improve the efficiency of shearing machine?

The key to improving the efficiency of plate shearing machine lies in optimizing the following aspects: equipment performance, process flow, personnel operation, automation assistance and management system. The following is a special improvement plan for metal plate shearing machine (such as nc hydraulic shearing machine, CNC shearing machine).

1) Equipment optimization and maintenance

– Use high-performance equipment

Use CNC shearing machine (CNC): control length, angle, quantity through program to improve accuracy and beat.

Configure hydraulic system with variable frequency drive: can increase shearing speed and reduce energy consumption.

Use high-quality blades: alloy steel or carbide, longer shearing life, and reduce sharpening frequency.

– Choose the right type of shearing machine

Choose the right shearing machine (such as mechanical shearing machine, nc shearing machine, CNC shearing machine, etc.) according to material thickness, material and shearing requirements to avoid overload or inefficiency.

– Reasonable blade gap adjustment

Set standard blade gap values for plates of different thicknesses and materials to improve shearing quality and efficiency and reduce rework.

– Implement regular maintenance

Check hydraulic oil level, pipeline leakage, and blade wear daily.

Ensure the normal operation of the lubrication system, check whether the hydraulic oil is clean and sufficient, and regularly replace wearing parts (such as blades, seals, etc.) to reduce downtime.

Establish a TPM system to avoid downtime caused by sudden failures.

2) Process optimization

– Optimize shearing layout design

Use nesting software (such as FastCAM, Lantek) to maximize material utilization and reduce material change time.

– Batch unified shearing

Centralize the processing of plates with the same thickness, material and size to reduce the frequent adjustment of blade gap and settings.

– Reduce non-processing time

Arrange the shearing sequence more reasonably (first large and then small, first straight and then corners), reduce handling and material change.

3) Personnel operation improvement

– Standard operating instructions (SOP)

Include loading and unloading steps, adjusting blade gap, daily inspection operations, and reduce human errors.

– Skill training

Proficient operators can reduce adjustment time and improve shearing rhythm.

Training the ability to identify abnormal sounds, hydraulic problems, and shearing quality problems.

– Combination of safety and efficiency

Use laser alignment or positioning ruler to improve operation accuracy and avoid repeated calibration.

4) Introduction of auxiliary devices

– Matching clamping/support device

Reduce the inaccurate positioning caused by the sagging of large plates, suitable for long plate shearing.

– Laser positioning or photoelectric sensor assistance

Achieve fast and accurate positioning, avoid repeated alignment, reduce errors and working hours.

5) Automation and digital upgrade

– Introduction of CNC system (CNC)

The CNC hydraulic guillotine shearing machine can control the cutting length and angle through the program to improve accuracy and batch operation efficiency.

– Matching automatic loading/unloading system

Using servo feeder, robotic arm or automatic stacking system can reduce manual operation time and improve continuous operation efficiency.

Automatic feeding table and robotic arm stacking can reduce manual handling time and improve cycle efficiency by at least 20~30%.

– MES system integrated management

Connect to the enterprise production management system to realize real-time monitoring of orders, scheduling, and equipment status, and improve overall process efficiency.

6) Management and information system application

– Reasonable production scheduling

Reduce the number of product switching, avoid frequent tool adjustment and program change.

– OEE efficiency analysis system

Record equipment operation time, downtime, shearing quantity and yield rate, and identify efficiency bottlenecks.

– MES system connection (optional)

Integrate with the production planning system to provide real-time feedback on cutting tasks and progress, and improve the plan execution rate.

3. Example of improving shearing efficiency in sheet metal processing plants

Problems | Improvement measures | Effect |

Frequent blade wear | Introduce wear-resistant alloy blades + set maintenance cycles | Service life increased by 50%, number of tool changes reduced |

Long waiting time for loading and unloading | Install automatic feeding and stacking racks | Cutting cycle increased by 25% |

Ununiform operating standards | Develop SOPs and train operators | Reduced manual rework rate by 40% |

Frequent switching of multiple varieties | Optimize production scheduling and process plates of the same specification in batches | Frequency of adjustments reduced, efficiency increased by 15% |

4. The importance of improving the efficiency of shearing machines

The importance of improving the efficiency of metal plate shearing machines is not only reflected in the increase in production capacity, but also directly related to the cost control, delivery guarantee, quality stability and overall competitiveness of enterprises in the fierce market.

1) Improve production capacity and expand production capacity

- Shearing machines are one of the key bottleneck processes in sheet metal processing, and their efficiency directly affects the progress of downstream bending, welding and other processes.

- Improving the shearing machines working efficiency can achieve more plate processing per unit time and expand production capacity without increasing equipment investment.

- During the peak order period, high efficiency means that more tasks can be completed quickly, enhancing the delivery guarantee capability of the enterprise.

2) Reduce manufacturing costs and increase profit margins

Cost sources | Benefits of improved efficiency |

Material costs | Optimize nesting and cutting layout, reduce waste, and improve material utilization |

Labor costs | Shorten the cutting time for each product and reduce labor input |

Energy costs | Reduced energy consumption per unit product and reduced equipment idling |

Equipment depreciation allocation | The same equipment can cut more products, and the depreciation per product is lower |

Improved efficiency = reduced overall unit product cost = increased profitability

3) Ensure shearing quality and reduce rework losses

- Efficiency improvement is usually accompanied by the introduction of automation, precision control and standardized work processes, which helps to:

- Reduce dimensional deviation, burrs, material deformation

- Reduce rework and rework rates

- Stabilize the processing quality of downstream processes (such as bending without deformation, high welding fit)

Stable shearing quality = higher first-time pass rate = less waste, higher customer satisfaction

4) Improve equipment utilization and return on investment (ROI)

Shearing machine is one of the key equipment with higher value in metal processing enterprises.

Improving work efficiency means:

- Increasing equipment utilization rate (OEE)

- Reducing downtime, idling, and waiting time

- Speeding up the equipment investment recovery cycle

- Enterprise managers often focus on: how to produce more and earn more without buying new equipment – efficiency improvement is the key answer.

5) Promote lean management and automation upgrades

The process of improving efficiency often involves:

- Process optimization (such as sample arrangement order, batch shearing)

- Operation standardization (such as SOP formulation)

- Automation transformation (such as automatic feeding, positioning system)

- Informatization linkage (such as MES system)

- This not only improves efficiency, but also promotes the transformation of enterprises to lean production and intelligent manufacturing, and improves the overall management level and risk resistance.

6) Enhance customer satisfaction and market competitiveness

- In the sheet metal processing industry with serious homogeneity, whoever can deliver products faster, more stably and at a lower cost will be more likely to win long-term cooperation with customers.

- As the core process of the front section, the efficiency of the shearing machine determines the starting speed of the entire production cycle and is the first step in the customer’s delivery commitment.

- Among the three core customer needs of “fast delivery, high quality and low price”, efficiency improvement directly supports all goals.

5. Summary

The strategic significance of improving shearing machine working efficiency:

Key value | Specific manifestations |

Capacity expansion | Achieve more order processing without adding equipment |

Cost reduction | Reduce labor, materials, energy, and equipment depreciation |

Stable quality | High precision, less rework, and fewer customer complaints |

Profit increase | Create more revenue per unit of product |

Management upgrade | Promote automation, digitalization, and leanness |

Market competition | Improve delivery capabilities, win customer trust and order volume |

5 core strategies to improve shearing machine efficiency:

Core points | Measures |

Improvement of shearing machine working efficiency | CNC, automation upgrade, blade quality improvement |

Process optimization | Nesting, batch management, cutting sequence optimization |

Standardization of personnel operation | Formulate SOP, skill training, set performance standards |

Introduction of automated auxiliary devices | Automatic feeding, laser positioning, support device, etc. |

Improvement of management system | OEE analysis, TPM maintenance, MES integrated production scheduling |