Table of Contents

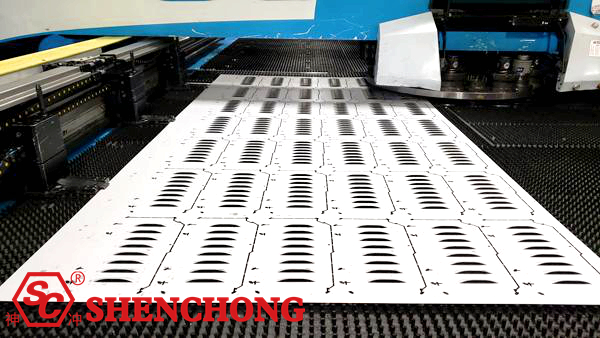

A sheet metal punching machine, also called a metal stamping machine or a press, is a mechanical device used to process sheet metal into a specific shape through a mold.

What is a sheet metal punching machine? It uses mechanical or hydraulic methods to apply strong pressure to the sheet metal, causing it to undergo plastic deformation such as punching, shearing, bending, stretching, stamping, and forming in the mold, and ultimately manufactures parts or products. How to correctly operate and use a sheet metal punching machine?

1. Working principle of sheet metal punching machine

The working principle of sheet metal punch pressing machine can be summarized as: using the slider to move up and down, applying pressure to the sheet through the die, causing it to produce plastic deformation or shearing, thereby achieving punching, bending, stretching, forming and other processing purposes.

1) Basic workflow

Preparation stage:

- Place the sheet on the lower die (or automatically feed).

- Thesheet metal punching machine prepares the die, the upper die is installed on the slider, and the lower die is fixed on the workbench.

Drive the slider downward:

- Themetal sheet punching press machine starts, and the drive device (such as a motor, hydraulic system) drives the slider to move downward from the top.

- The slider drives the upper die to press against the sheet.

Sheet deformation under force:

- The sheet is squeezed in the die.

Depending on the shape of the die and the pressure, the sheet undergoes:

- Punching (cutting or punching)

- Bending (forming an angle)

- Drawing (becoming a three-dimensional structure)

- Imprinting/shaping, etc.

Slider rises and resets:

- After the slider moves to the bottom dead center, it automatically rises to complete a stamping cycle.

- The workpiece is demolded and the operator or automated equipment removes the finished product, ready for the next cycle.

2) Working principle of drive mode (by type)

- Mechanical punch: flywheel stores energy, crankshaft drives the slider to move. The structure is similar to that of a car engine, suitable for high-speed punching.

- Hydraulic punch: hydraulic oil is used to push the piston to generate linear pressure, and the slider is pressed down for processing. Suitable for high tonnage, large parts or complex processes.

- Servo punch: electric servo motor controls the slider stroke, speed and stop position to achieve high-precision control and energy saving.

3) Key factors affecting punch

- Pressure (tonnage): determines whether thick plates or hard materials can be processed.

- Slider stroke and speed: affect molding quality and production efficiency.

- Mold design: determines the shape, precision and service life of the finished product.

- Automation system: such as feeding device and manipulator, which can improve efficiency and safety.

2. How to use a sheet metal punch press?

Using a sheet metal punching machine requires following certain operating procedures and safety specifications to ensure the normal operation of the equipment, stable product quality, and personnel safety. The following is a detailed explanation for you:

1) Standard steps for using a sheet metal punching machine

– Preparation

- Check the equipment status: Confirm that the punch is in good condition, without abnormal sounds, oil leakage, etc.

- Check whether the mold is firmly installed.

- Lubrication and maintenance: Add lubricating oil and check whether all moving parts are well lubricated.

- Install/adjust the mold: Select the correct mold according to the product requirements and correct the position.

- Set parameters (applicable to servo or CNC punch): such as stroke, speed, continuous/single mode, etc.

- Check whether the emergency stop device is normal and effective.

– Place or connect the sheet

- Manual feeding: Place the metal sheet accurately under the mold.

- Automatic feeding system: such as coil automatic feeder, manipulator or servo feeder connected to the punch.

– Test run

- Manual single punch test mold: Run at low speed for several cycles to check the quality of the finished product, mold position, and punching pressure.

- Observe whether there is interference (such as jamming between molds, poor contact between slider and sheet).

- Adjust the mold gap or mold height if necessary.

– Formal production

- Start the punch press and start continuous punching or inching punching.

- Maintain a uniform feeding rhythm to ensure that the sheet is in the correct position each time it is punched.

- Observe whether the product is qualified (size, deformation, burrs, etc.).

- Periodically inspect products during production.

– Post-processing

- Stop → Unload mold → Clean → Turn off power.

- Clean up the site and place molds, finished products and waste materials in categories.

2) Precautions for safe operation

- Wear protective equipment: such as safety glasses, gloves, protective shoes, etc.

- It is strictly forbidden to put the mold by hand: it is strictly forbidden to put the plate or finished product by hand during the stamping process, and suction cups, clamps or automatic mechanisms should be used.

- Emergency stop button: confirm that the emergency stop button is sensitive and effective before sheet metal punching machine

- Regular maintenance: including lubrication, replacement of wear parts, adjustment of mold gap, etc.

- Mold replacement and lock: power must be turned off and padlock alarm must be used during mold replacement.

3) Summary of key points for use

- Preliminary preparations are in place, and the mold and plate are selected correctly.

- Test molds are carefully debugged to avoid mold damage or product defects.

- Operation safety first, do not put your hands into the mold area.

- Regular inspection and maintenance to extend the service life of the equipment.

- Can be used with automation systems to improve production efficiency and stability.

3. Precautions for using metal sheet punching machines

1) Precautions for safe operation (must read)

Item | Precautions |

Inspect before operation | – Check whether the punch press and electronic control system are normal. – Check whether the mold is installed firmly and whether the gap between the slider and the mold is appropriate. – Check whether the emergency stop switch and photoelectric protection device are sensitive and effective. |

Wear protective equipment | – Protective glasses, cut-resistant gloves and safety shoes must be worn. – Do not operate rotating parts while wearing gloves. |

Do not enter the mold area with your hands | – It is strictly forbidden to place or take out materials by hand during the stamping process. Feeding mechanism, suction cup or clamp should be used. – It is recommended to use two-hand operation button or foot switch + photoelectric protection system. |

Do not adjust or clean the mold until the equipment is stopped | – It is forbidden to adjust the mold or clean the waste during the operation of the punch press. – All maintenance must be carried out with the power off and the tag hanging. |

Lock the power supply when changing the mold | – During mold replacement, the power must be turned off, the machine must be locked, and a warning sign must be hung to ensure that the equipment is not started by mistake. |

2) Precautions during operation

- Ensure that the sheet is placed correctly: the feeding position should be accurate to avoid damage to the mold caused by misaligned stamping.

- Pay attention to the matching of stamping rhythm and feeding speed.

- Pay attention to mold temperature and wear, check and lubricate or replace regularly.

- Check product quality regularly to prevent defective products from appearing for a long time.

- Keep the operating table clean to prevent foreign objects from entering the mold area and causing mold jams or accidents.

3) Precautions for equipment maintenance

- Lubrication maintenance:

Regularly check whether the oil volume of each lubrication point is sufficient, especially the slider, connecting rod, guide rail and other parts.

- Fastener inspection:

Regularly check whether the bolts and pins are loose, especially the connection between the mold, slider and connecting rod.

- Mold inspection:

Check whether the mold gap is appropriate and whether the punch is worn, cracked or missing.

- Electrical system maintenance:

Check whether the PLC, buttons, relays, etc. are sensitive, whether there is a short circuit or poor contact.

- Fire equipment configuration:

A dry powder fire extinguisher should be equipped near the machine to prevent fire caused by hydraulic oil or electrical short circuit.

4) Other management considerations

- Operators must be certified and trained to understand the structure and safety regulations of the punch press.

- The mold must be tested before each production, and batch processing can only be carried out after confirmation.

- Establish equipment operation logs to record operating time, failures, maintenance time, etc.

- Set up safety fences and warning signs to prevent unauthorized personnel from approaching the equipment operation area.

5) Common accident types and preventive measures

Accident type | Causes | Prevention |

Hand crush | Improper hand-entry or material feeding | Use two-hand buttons or photoelectric protection devices |

Mold damage | Improper mold installation, sheet misalignment | Calibrate the mold and check the sheet positioning |

Electrical failure | Aging circuit, humidity | Check the electrical system regularly and keep it dry |

Stamping waste flying out and injuring people | No protective cover | Install protective covers or baffles |

4. Summary of metal punching machine operating procedures and precautions

Before operating the sheet metal punching machine, the equipment condition should be checked to ensure that the mold is firmly installed, well lubricated, and the safety device is normal. Operators must wear protective equipment and strictly follow the process parameter settings.

During the punching process, it is strictly forbidden to put your hands into the mold area, and special tools must be used to feed and remove parts. When debugging, replacing or cleaning the mold, you must first turn off the power, hang a sign and confirm that the slider has stopped.

During production, the quality of products should be regularly inspected, and if abnormalities are found, the machine should be stopped immediately for investigation. Keep the site clean and tidy to prevent oil stains and waste from affecting the safety of operations. Operators must be trained and certified to work, strictly abide by safety regulations, and ensure human-machine safety and product quality.