Table of Contents

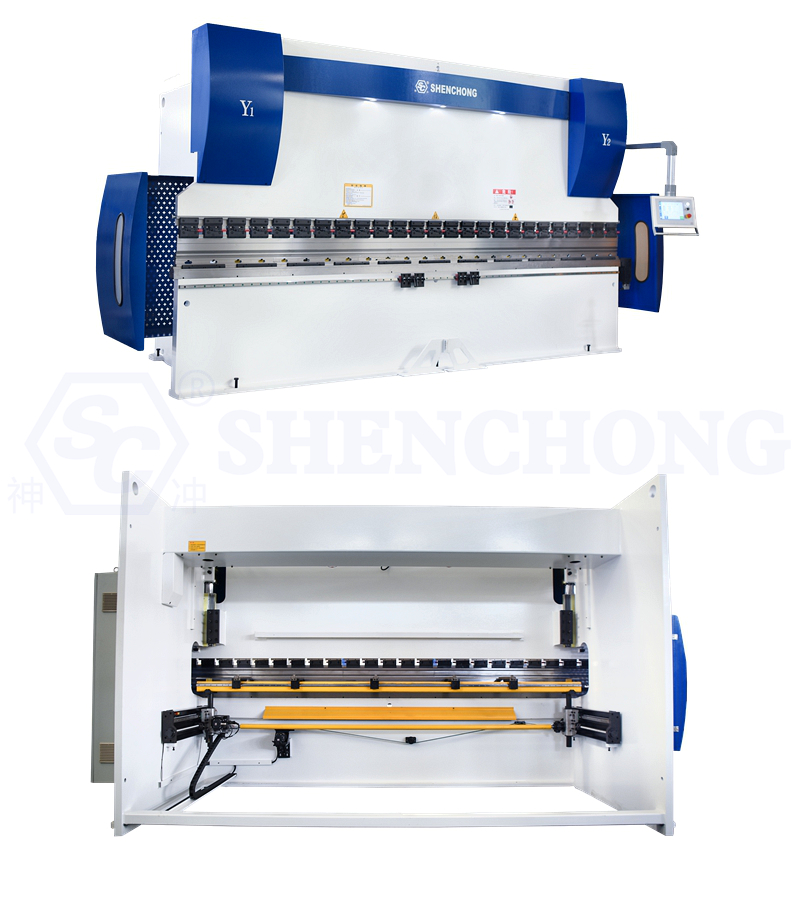

The 175ton CNC press brake machine is a high-precision hydraulic equipment used for sheet metal forming, primarily for bending and forming metal sheets such as carbon steel, stainless steel, and aluminum. Its core function is to precisely bend the metal sheet into the required angle and shape through the relative movement of upper and lower dies.

The equipment combines a hydraulic transmission system, a CNC system, and synchronous control technology to achieve high-precision, high-efficiency, and repeatable bending processing, suitable for industries such as sheet metal, chassis and cabinets, automotive parts, building curtain walls, and home appliances.

1. Key Technical Features Of 175ton CNC press brake

The 175ton CNC press brake for sale is a high-precision hydraulic machine tool used for bending sheet metal parts. It is widely used in industries such as metal products, sheet metal processing, automotive, building curtain walls, electrical control cabinets, and machinery manufacturing.

This equipment adopts an all-steel welded structure + hydraulic proportional servo control + CNC system, achieving synchronous control, automatic compensation, and angle control of the slider. It features high precision, high stability, high efficiency, and low noise.

- High Rigidity Overall Structure

- Utilizes a welded frame throughout the machine, treated with high-temperature tempering to ensure stability and prevent deformation.

- The C-shaped structure guarantees high left-right synchronization accuracy, reducing angular errors.

- Hydraulic Servo Synchronization System

- Two hydraulic cylinders are independently controlled, with real-time position detection via a linear encoder to achieve closed-loop control.

- Synchronization accuracy reaches ±0.01 mm, ensuring high consistency in bending angles.

- CNC System (Controller)

- Configurable with ESA, Delem, EL, and other brand control systems.

- Supports angle programming, automatic calculation of bending compensation, rebound compensation, and bending sequence optimization.

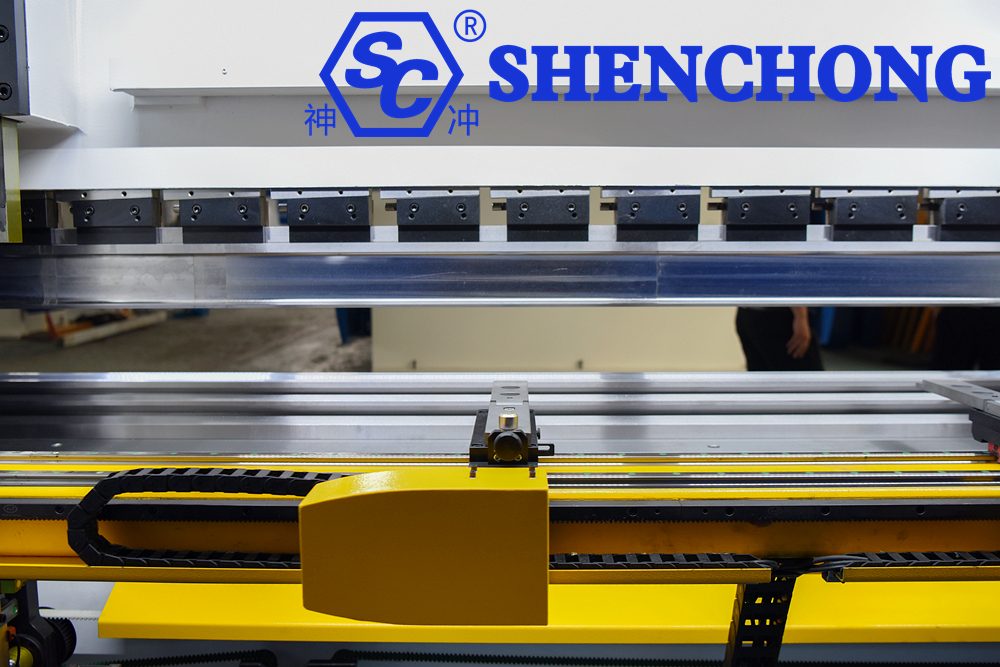

- Backgauge System

- Driven by an electric or servo motor, equipped with a high-precision ball screw and linear guide.

- Positioning accuracy ±0.02 mm, supporting multi-axis control (X, R, Z1/Z2).

- Quick Die Change and Safety Devices

- Upper die quick clamping system (Promecam standard) or hydraulic clamps.

- Equipped with photoelectric protection devices, an emergency stop button, and a slide descent anti-fall system.

- Hydraulic System

- Employs imported hydraulic components (such as Bosch Rexroth and Yuken), resulting in low noise and long service life.

- Features automatic oil return and leak-proof design, ensuring system stability and reliability.

- Angle Compensation Function

- Optional hydraulic or mechanical compensation systems ensure full-length bending accuracy.

2. Typical Technical Parameters (Taking WEK-175T/3200mm CNC Hydraulic Press Brake Model as an Example)

- Parameter Table

Item | Parameters |

Nominal Pressure | 1750 kN (175 tons) |

Bending Length | 3200 mm |

Column Spacing | 2600 mm |

Throat Depth | 400 mm |

Slider Stroke | 200 mm |

Maximum Opening Height | 470 mm |

Main Motor Power | 15 kW |

Number of Hydraulic Cylinders | 2 units |

Worktable Length | 3200 mm |

Weight (Approx.) | 11 tons |

Dimensions (L×W×H) | 3700 × 1800 × 2800 mm |

- Structural Components

- Frame: Composed of columns, beams, and a worktable, featuring a compact structure and high stability.

- Slider: Driven by hydraulic cylinders, it moves up and down to achieve the bending action.

- Hydraulic System: Employs imported hydraulic valve sets, ensuring smooth operation and adjustable pressure.

- CNC System: Controls slider stroke, back gauge position, angle compensation, etc., achieving full automation.

- Back Gauge Device: Driven by a servo motor and precision ball screw transmission, ensuring high positioning accuracy.

- Compensation System: Utilizes hydraulic or mechanical compensation structures to ensure consistent bending angles for long plates.

- Electrical System: Complies with CE safety standards and features overload protection and emergency stop functions.

- Safety Devices: Includes photoelectric protection devices, a fall arrestor system, and foot switch control.

- Optional Configurations

- Control System: Delem DA-66T/ESA S630/EL 15T/EL 18T

- Number of Backgauge Axes: X, R, Z1/Z2, X1/X2 (Multi-axis optional)

- Compensation System: Hydraulic or mechanical compensation

- Die Type: Standard upper die/V-type lower die, split die, precision die

- Safety System: Light curtain protection, laser protection system, foot interlock device

- Additional Devices: Bending follow-up support arm, angle detector, automatic programming system

3. Applicable Industries

- Sheet metal processing centers

- Kitchenware and electrical control cabinet manufacturing

- Elevator and air conditioner housings

- Automotive parts and decorative components

- Building curtain wall and window profile processing

- General machinery manufacturing industry

4. Operation and Maintenance

Operating Instructions:

- Before starting the machine, check the oil level, hydraulic valves, and electrical connections.

- Power must be disconnected and the slider locked when adjusting the mold.

- A trial bend should be performed before adjusting the bending angle.

Maintenance:

- Replace the hydraulic oil filter element every 6 months.

- Check the synchronization accuracy of the grating ruler and slider every 12 months.

- Lubricate the lead screw and guide rails regularly.

- For long-term shutdown, disconnect the power and release the oil pressure.

The 175ton CNC press brake machine is a high-precision hydraulic device for bending and forming metal sheets. Combining advanced hydraulic servo control technology with a CNC system, it achieves high-precision, automated, and intelligent control of the bending process. This equipment is widely used in sheet metal processing, electrical cabinets, elevators, automobiles, building curtain walls, kitchenware, and machinery manufacturing.

With its core advantages of high precision, high efficiency, and high stability, the 175ton CNC press brake machine is an ideal choice for medium to large-sized sheet metal processing enterprises. It not only improves production quality and efficiency but also significantly reduces reliance on manual labor and energy consumption, realizing an upgrade from traditional bending to intelligent manufacturing.