Table of Contents

SC 6015 steel profile intelligent storage 5tons 10layers is a three-dimensional storage system specifically designed for steel profiles (such as square tubes, round tubes, angle steel, channel steel, H-beams, etc.).

The system adopts a modular structure design and achieves automatic storage and retrieval, precise positioning, and maximized space utilization through electrical control or PLC intelligent control. It is widely used in industries such as metal processing, structural manufacturing, electromechanical equipment, and warehousing and logistics.

1. Main parameter configuration: 6015 steel profile intelligent storage 5tons 10layers (for reference)

Item | Parameter Description |

Model | 6015-5t-10layer |

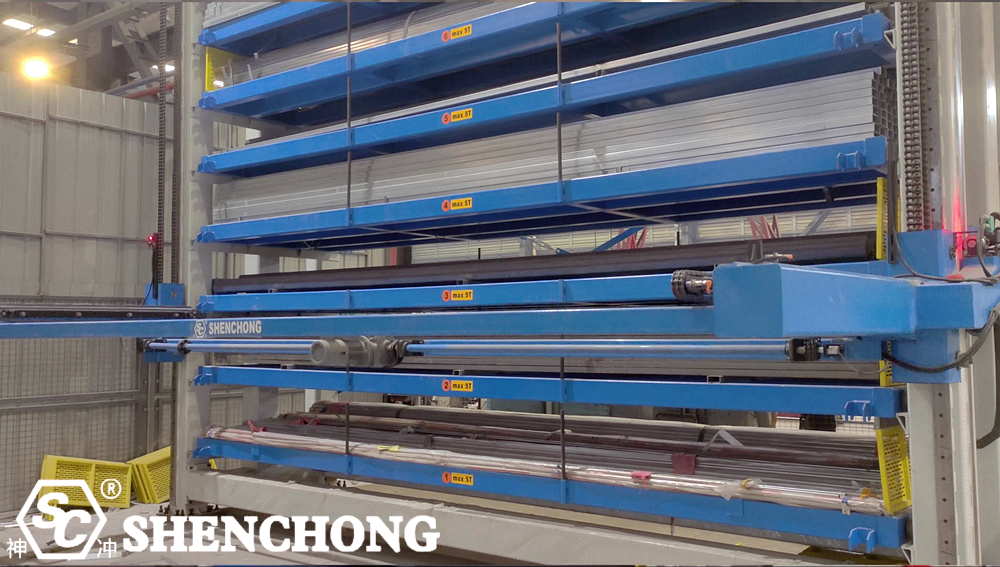

Number of Layers | 10 layers (can be customized into a multi-layer structure) |

Single Layer Dimensions | 6000 mm × 1500 mm |

Single Layer Load Capacity | Approximately 5 tons |

Applicable Materials | Steel pipes, structural steel, aluminum, stainless steel pipes, square steel, long materials, etc. |

Single Length | Within 6 meters |

Drive Type | Electric chain / servo motor (optional) |

Safety Devices | Limit switches, alarms, overload protection, emergency stop button |

Optional Functions | Barcode/QR code management, ERP interface, inbound/outbound record system |

2. 6015 Steel Profile Intelligent Storage System Structure

1) Main Frame Structure

- Utilizing high-quality carbon steel profiles welded together, the entire structure undergoes CNC machining and powder coating for rust prevention.

- Columns, beams, and support rods are connected by bolts, ensuring a stable structure and facilitating installation and maintenance.

- Multi-layer or multi-column layouts can be customized according to factory height and material specifications.

2) Storage Units (Pattern/Drawer Layers)

- Each layer features an independent pallet or drawer-type load-bearing unit, which can be independently removed.

- Maximum load capacity per layer is approximately 5 tons.

- Surface roller/slide rail design ensures smooth entry and exit, supporting manual or electric drive.

3) Material Picking and Lifting Mechanism (Optional)

- Electric chain lifting system or servo drive device achieves vertical lifting.

- In conjunction with a lateral movement mechanism, it can automatically complete the entry and exit actions.

- An automatic identification and positioning system can be optionally added for intelligent scheduling.

4) Control System

- Electric type: Uses motor drive + button control to achieve lifting/entry/exit.

- Intelligent type: PLC control + touch screen interface, enabling one-click inventory release and automatic positioning.

- Supports barcode/QR code recognition, automatic weighing, data recording, and other functions.

5) Safety and Protection System

- Fully equipped with limit switches, photoelectric sensors, overload protection, and emergency stop functions.

- Mechanical anti-fall structure ensures safe lifting operation.

- Features fault alarm and operation recording functions.

3. System Features and Advantages

- High Space Utilization: The three-dimensional design increases storage density by 3-5 times, making it especially suitable for spaces with limited room.

- High Inbound/Outbound Efficiency: Electric or automatic control enables fast and accurate material retrieval, reducing single outbound time to less than 30 seconds.

- Safe and Reliable Operation: The system features overload protection, limit alarms, and fall protection locks, eliminating the risk of human error.

- Intelligent Management: Optional WMS warehouse management system, compatible with ERP/MES data, enabling visualized material management.

- Modular Design: Modular structure, easy installation and maintenance, and flexible expansion of layers and capacity.

- Wide Applicability: Can store various long profiles, steel pipes, aluminum profiles, stainless steel bars, etc.

Summary Table:

Advantages | Description |

Stable structure | High-strength steel structure design ensures reliable load-bearing capacity. |

Efficiency improvement | Inbound and outbound efficiency is increased by 2-3 times. |

Space saving | Three-dimensional layout saves over 60% of floor space. |

Intelligent management | Supports data-driven management and visual monitoring. |

Safe operation | Multiple protection systems reduce risks associated with manual operations. |

4. Applicable Industries

- Steel structure manufacturing

- Metal processing and cutting centers

- Pipe and profile trading warehouses

- Machinery equipment manufacturing workshops

- Raw material warehouses for automated production lines