Table of Contents

In the wave of digital transformation, intelligent metal storage warehouse have become a core support tool for enterprises to reduce costs and increase efficiency, and for individuals to manage data efficiently. The selection of an intelligent storage bin directly affects data processing efficiency, security protection level, and long-term operating costs under different business scenarios and needs.

Below is a systematic overview of the main classifications and differences of intelligent metal storage system, covering common industrial application types, structural characteristics, applicable scenarios, and their respective advantages, facilitating selection or use in technical specifications.

1. Intelligent Metal Storage Warehouse Classification By Storage Material Type

1) Sheet Metal Storage System

Applicable Materials:

Flat materials such as steel plates, stainless steel plates, and aluminum plates

Structural Features:

- Multi-layer drawer-type pallets (e.g., 10-layer, 15-layer, 20-layer).

- Utilizes a lifting mechanism/elevator-style lifting structure.

- Can be integrated with laser cutting machines and bending machines for automated material loading.

Advantages:

- Saves floor space (vertical storage).

- Clear sheet material classification and fast inbound/outbound speed.

- Can be integrated with MES for unmanned delivery.

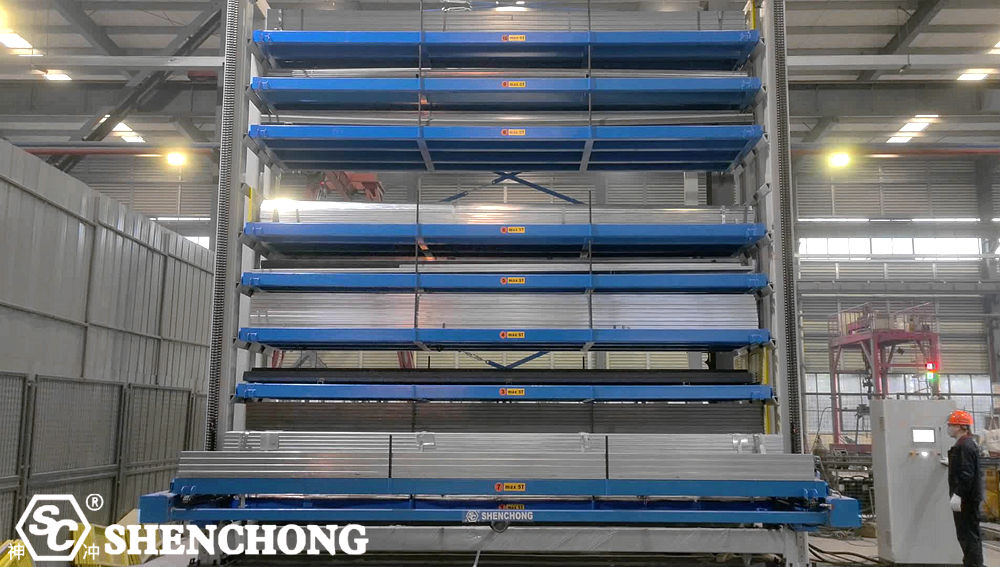

2) Profile Storage System

Applicable Materials:

Square tubes, round tubes, angle steel, channel steel, aluminum profiles, long strip profiles

Structural Features:

- Multi-layer storage compartment structure, capable of supporting long materials (4–6m).

- Automatic racking + electric carriers (stall crane/shuttle car).

Advantages:

- Suitable for storing long profiles, lengths that are difficult to manage efficiently manually.

- Features anti-mixing, anti-loss, and quick recall functions.

3) Coil Storage System

Applicable Materials:

Steel coils, aluminum coils, stainless steel coils

Structural Features:

- Multi-layer coil pallets, single pallet load capacity varies from 0.6 to 5 tons.

- Used in conjunction with uncoilers, slitting machines, etc.

Advantages:

- Prevents coil deformation, increases storage density.

- Automatically identifies coil diameter, weight, and batch.

4) Storage System For Small Parts/Stamped Parts

Applicable Materials:

Small hardware parts, stamped parts, intermediate products from bending and processing

Structural Features:

- Small bin storage, similar to a “mini AS/RS”.

- Utilizes a small stacker crane or multi-level rotating storage unit.

Advantages:

- Refined management, suitable for multiple product types and small batches.

- Synchronized with production line cycle time, high picking efficiency.

2. Storage System Classification By Structural Form

1) Single-Tower Storage Unit

Structure and Design:

- Constructed from rectangular tubing, featuring a simple and elegant structure that facilitates assembly, disassembly, and handling.

- The storage unit typically has 8 layers, with a fixed loading height on each layer, ensuring strong load-bearing capacity.

- Equipped with a double-column lifting mechanism, using a motor-driven chain to raise and lower pallets and materials.

Storage Capacity:

Suitable for storing medium-sized quantities of materials or sheets, offering high space utilization.

Application Scenarios:

Suitable for small and medium-sized enterprises or production lines, meeting basic storage and handling needs.

Cost and Benefits:

Relatively low cost, suitable for enterprises or production lines with limited budgets.

2) Dual-Tower Storage System

Structure and Design:

- Compared to a single-tower storage system, a dual-tower storage system is structurally more complex due to the need to manage the coordination and synchronization between the two towers.

- Dual-tower storage systems typically offer higher storage capacity and flexibility, adapting to diverse storage requirements.

Storage Capacity:

Storage capacity is generally greater than that of a single-tower storage system, making it suitable for scenarios requiring the storage of large quantities of sheet metal or materials.

Application Scenarios:

Suitable for large enterprises or production lines handling large quantities of sheet metal or materials, providing higher storage efficiency and flexibility.

Cost and Benefits:

Although the cost is higher, the greater storage efficiency and flexibility offered may result in greater long-term economic benefits.

3) Multi-Tower Warehouse

Structure and Design:

- A multi-row warehouse consists of multiple parallel storage units forming one or more storage lines.

- Each storage unit is similar to a single-tower or dual-tower warehouse design, but the overall layout is more compact and efficient.

- Multi-row warehouses are typically equipped with automated conveyor systems for rapid storage, retrieval, and handling of sheet materials or other materials.

Storage Capacity:

By increasing the number of storage units, storage capacity can be significantly increased, making it suitable for large warehouses or production lines.

Application Scenarios:

Suitable for large warehouses, production lines, or distribution centers to meet large-scale, high-efficiency storage and handling needs.

Cost and Benefits:

Highest cost, but offers the greatest storage capacity and efficiency, suitable for scenarios with extremely high storage and handling requirements.

3. Classification by degree of automation

Types | Automation Level | Features |

Standard intelligent metal warehouse | Semi-automatic | Manual barcode scanning/touchscreen inventory management; partial data management |

Automatic loading, automatic unloading, and integration with other equipment | Suitable for unmanned factories | |

Flexible manufacturing cell (FMS) supporting material warehouse | Integration with laser cutting machines, bending machines, and robots | Suitable for highly automated production lines |

4. Summary of Key Differences (Core Comparison)

By Storage Material:

- Sheet Metal Warehouse: Multiple layers, large pallets, compatible with laser cutting

- Profile Warehouse: Long material design, stacker crane or shuttle

- Coil Material Warehouse: High pallet load capacity, anti-deformation structure

- Small Item Warehouse: Dense storage, fast picking

By Structure:

- Single Tower Storage: Suitable for small and medium-sized enterprises or production lines. Low cost. Small footprint.

- Double-Tower Storage Ssytem: Suitable for scenarios requiring the storage of large quantities of sheet metal or materials. Higher cost. Offers higher storage efficiency and flexibility.

- Multi-Tower Storage System: Significantly increases storage capacity, suitable for large warehouses or production lines. Highest cost. Suitable for scenarios with extremely high storage and handling requirements.

5. Applicable Industries

- Sheet metal processing plants (laser processing + bending)

- Aluminum profile manufacturers

- Steel structure/section steel processing plants

- Home appliance/chassis/cabinet manufacturing

- Automotive parts

- Heavy industry (steel coils, sheets)

- Smart factory transformation projects

6. Selection Recommendations (Quick Guidance)

If:

- Limited space and funds → Single-tower storage

- Need to store large quantities of sheet metal → Dual-tower storage

- Complex material types, high degree of automation desired → Multi-tower storage

- Mainly coil materials → Intelligent coil storagesystem

- Mainly square tubes/aluminum profiles/long strips → Intelligent profile warehouse

7. Summary

Comprehensive Classification Diagram:

Intelligent Metal Storage Warehouse = 4 Major Categories + 3 Structures + 3 Levels of Automation + 3 Levels of Load Capacity

By Material:

- Plate

- Coil

- Profile

- Workpiece

By Structure:

- Single-Tower Warehouse

- Dual-Tower Warehouse

- Multi-Tower Warehouse

By Automation:

- Semi-Automatic

- Fully Automatic

- Intelligent Production Line Level

By Load Capacity:

- Light Load

- Medium Load

- Heavy Load

The classification of intelligent metal storage warehouses reveals the technological evolution path from managing “things” to managing “information,” and then to managing the “integrated ecosystem of things and information.” By accurately identifying one’s own data scale, security needs, and business characteristics, the most suitable intelligent storage solution can be selected to fully unleash the value of data management.