Table of Contents

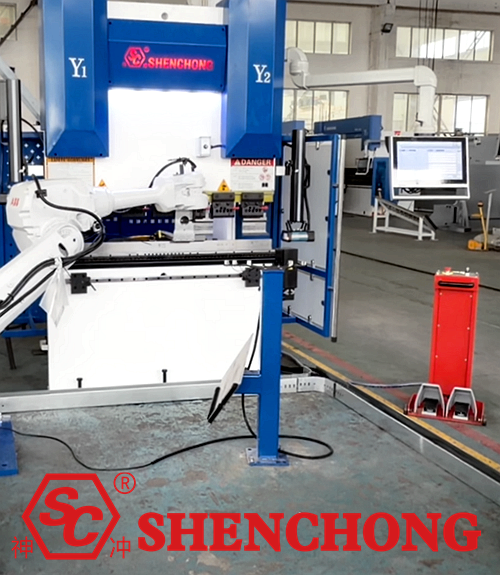

This is SC press brake robot bending cell ordered by an Italian customer. This Italy robotic bending unit consists of a WDK CNC press brake 80T/1500 linked with a robot ABB IRB 4600-60. If your production requires high repeatability, low energy consumption, and scalability, then this automated bending unit is the best choice.

1. Hybrid Electric Servo CNC Press Brake WDK-80X1500

This Italy WDK press brake is a CNC plate bending machine for small and medium-sized sheet metal production, based on a hybrid energy system of servo-motor drive + hydraulic actuation. It features high-performance DELEM DA-58T graphical CNC control and 6+1 axis automatic back gauge/cropping functions. Suitable for mass production of precision medium-sized to thin medium-sized sheet metal parts, it balances energy consumption reduction with high-precision bending.

1) Key Technical Parameters of Italy robotic bending unit press brake

- Rated Pressure: 80 tons.

- Worktable (Bending Length): 1500 mm.

- Main Axes: 6 + 1 axis

Structure:

- Frame/Bed: Adopts an integral welded box-type bed with aging/annealing treatment (stress relief) to ensure rigidity and long-term accuracy.

- Slide and Guide Rail: The working slide mainly adopts linear guide rails or precision guide columns. The slide stroke/speed can be controlled by a servo.

- Back gauge: Typically equipped with a ball screw/synchronous belt or servo drive back gauge, with positioning accuracy up to ±02 mm (depending on the grating/encoder and mechanical precision).

- Hydraulics & Valves: High-quality hydraulic valves (e.g., Rexroth) and independent oil tanks (common in hybrid systems) ensure stable pressure and faster response.

DELEM DA-58T Controller:

The DELEM DA-58T is a 2D graphical touch controller for synchronous bending.

Key features include:

- Graphical touchscreen programming, visual bending sequence and simulation (collision detection, automatic sequence calculation).

- Supports Tandem capability and CNC crowning control.

- Supports closed-loop/open-loop valve control, servo/variable frequency drive interfaces, USB and network interfaces, and offline profile software support.

2) Advantages of the hybrid hydraulic servo system

- Energy saving: The servo motor is powered on demand, and the use of variable frequency/servo drives for the oil pump significantly reduces energy consumption.

- Low temperature rise and low noise: Compared to traditional constant flow pump systems, the oil temperature is lower and the noise is less.

- Speed and energy recovery: More flexible speed control and energy management are possible at different stages of approach, bending, and retraction, improving production cycle time.

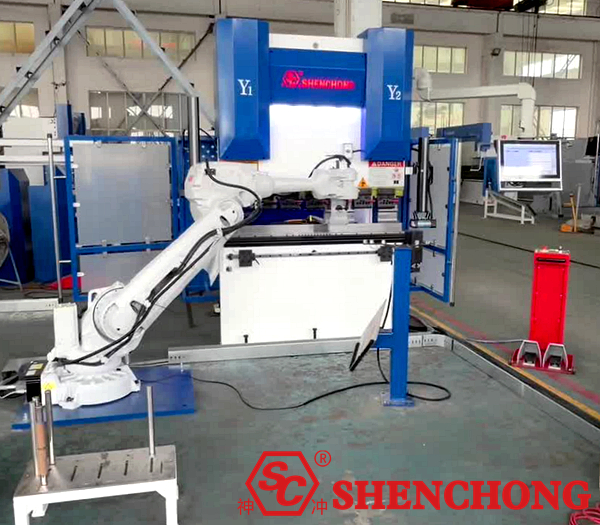

2. Italy Robotic Bending Unit ABB IRB 4600-60 Robot

Robot ABB IRB 4600 is a highly efficient, general-purpose robot optimized for shorter production cycles, particularly suitable for scenarios where compact robots can help build high-density production cells. The IRB 4600 enables more compact production cells, thereby increasing output and product quality, ultimately improving production efficiency.

ABB IRB 4600-60 Specifications:

Parameters | Values |

Number of Axes | 6-axis |

Load Capacity | Maximum weight 60 kg |

Reach | 2.05 m (approx. 2050 mm) |

Repeatability | ± 0.05 mm |

Weight | Approx. 435 kg |

Installation Method | Supports various installation methods including ground, tilt, and suspended installations |

Controller | Compatible with IRC5 controller |

Key Advantages and Features:

- High Efficiency/Fast Cycle Time

Compared to industry standards, the IRB 4600’s cycle time is reduced by approximately 20–25%.

Its acceleration and top speed are among the best in its class, meaning a significant increase in throughput and production efficiency on automated production lines.

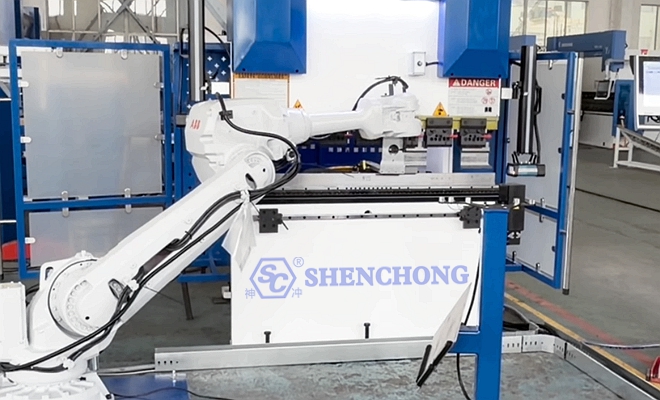

- Compact Design and Space Saving

Compact structure: The base is small (approximately 512 mm × 676 mm), and the arm and wrist design are also slim and compact. This allows the robot to be placed closer to the equipment/machine being serviced, saving shop floor space.

Suitable for “high-density” production lines: Particularly advantageous for applications with limited space, requiring multiple robots to work collaboratively, or working close to machinery.

- Excellent Flexibility and Installation Adaptability

Supports multiple installation methods: floor, tilted, shelf/semi-shelf, inverted, etc.

Adaptable to different shop floor layouts and equipment structures. It can be flexibly deployed for various applications such as loading/unloading, machine tending, assembly, handling, welding, and gluing.

- Excellent Precision and Reliability

Repeat positioning accuracy is ±0.05–0.06 mm, meeting the requirements of many industrial applications with high precision requirements (such as assembly, welding, and precision handling).

The structural design and control system (IRC5) are mature and stable, and can be integrated with various equipment/systems (such as PLCs, automated production lines, and peripheral equipment).

- Good Protection and Environmental Adaptability

Standard protection rating is IP67, providing dustproof, waterproof, and pollution-proof capabilities, suitable for harsh/complex industrial environments (such as casting, spraying, cleaning, and heavy industry).

The ABB IRB 4600-60 is a general-purpose industrial robot that combines high speed, high precision, high load capacity with flexibility, compactness, and protection. For automated production lines requiring medium to high load handling, assembly, welding, loading/unloading, and material processing, it is often a cost-effective, stable, and reliable choice. Its advantages are particularly evident in modern factories with limited space, requiring multi-robot collaboration and high-density deployment.

3. Advantages Analysis: SC Italy Robotic Bending Unit For Sale

This combination offers a well-balanced automation solution for production lines with small to medium batch sizes and medium-volume, multi-variety production. The robot’s payload/arm span is matched with a 1.5 m bending length, and the DA-58T multi-axis/graphical programming and collision detection support complex processes, resulting in significant improvements in productivity, safety, and consistency.

1) Capacity and Cycle Time

Shorter Cycle Time:

Automated loading and unloading by robots allows for continuous preparation of the next piece and reduces operator idle travel (loading/unloading combined with fixture movements typically significantly reduces waiting time for manual loading/unloading per piece). The IRB 4600’s high acceleration/high speed design reduces handling time.

Parallelized Processes:

Robots can complete the next step of work piece preparation or unloading while the bending machine is bending, thereby increasing the bending machine’s spindle utilization (total throughput).

Rough Data Reference:

For common processes involving 1.5 m small parts, automated loading and unloading can reduce the overall operation time per piece from 30–60 s manually to 15–30 s (affected by fixture complexity and number of bends).

2) Product Quality and Consistency

High Repeatability:

The IRB 4600 achieves repeatability of ~0.06 mm. The DA-58T provides precise bending sequence and back gauge multi-axis control. Together, these ensure dimensional consistency and traceability of batch parts.

Reduced Human Error:

Precise robot gripping and positioning, along with programmed bending sequences by the controller, reduce rework rates caused by human error and variations in operation.

3) Safety and Working Environment

Reduced Direct Contact Hazards:

Robots replacing manual labor in the bending area for work piece handling significantly reduce the risk of pinching/squeezing injuries (but proper design of safety barriers/gates/safety PLCs is required).

4) Automation and Process Flexibility

DA-58T Multi-Axis and Graphical Programming:

Supports 2D graphical programming, automatic bending sequence calculation, and collision detection, reducing the programming complexity of robot-machine tool linkage and facilitating rapid part changeovers and small-batch, multi-variety production.

"6+1 Axis" Process Capabilities:

The machine tool itself has multiple back gauge axes, enabling complex positioning, bending, and multi-station operations. When the robot acts as the loading/unloading robot (or the 7th axis follower), it supports complex processes and multiple bending connections (e.g., flipping, multiple gripping). Modular Fixture Design: Electric/pneumatic grippers and quick-change fixture pallets facilitate production line integration with robots.

5) Economic Efficiency and Return on Investment

Reduced Labor Costs and Increased Output:

Automated multi-shift systems are easier to implement, and high uptime directly leads to lower unit costs. Reducing operating costs and scrap, and increasing output are the key to the return on investment for robots.

Reduced Material Loss/Rework Rate:

More stable positioning and bending results reduce rework and scrap, indirectly saving costs.

Scalability:

Initially, single-machine automated loading and unloading can be implemented, and later expanded to racks, palletizing, or integrated production lines, making the investment valuable for expansion.

6) Engineering Feasibility

Robot Parameter Adaptability:

The IRB 4600-60 (2.05 m 60 kg) is well-matched in terms of reach/load capacity for loading and unloading applications with a 1.5 m bending machine (a 30–40 kg margin is often reserved for the fixture and work piece for greater stability). Controller Compatibility: The DELEM DA-58T supports Ethernet and digital I/O and has multi-axis synchronization capabilities, making it suitable for integration with PLCs/robots via standard digital handshake or industrial Ethernet.

4. Typical Applications

Precision chassis/panel bending, batch processing, and automated bending lines linked with robots.

This Italy robotic bending unit model is highly suitable for work pieces with a width ≤1500 mm and thickness/material within the equipment’s rated capacity (e.g., common 0.5–6 mm steel/stainless steel/aluminum). If your production requires high repeatability while minimizing energy consumption and offering automation scalability, this WDK hybrid servo 80t/1500mm 6+1 axis model is a very suitable mid-range option.

5. Daily Maintenance and Wear Parts

- Check and regularly replace hydraulic oil and filters (according to the manufacturer’s recommended intervals).

- Lubricate the slider/guide rails and the back gauge lead screw (or rack).

- Protect the controller and electrical cabinet from moisture and dust; ensure unobstructed cooling airflow.

- Regularly calibrate the back gauge positioning accuracy and reference point (DA-58T provides a reference point/zeroing function).