Table of Contents

First, the goal of using sheet metal laser cutting machine correctly is not simply to pursue speed, but to achieve safety, stability, high precision, and minimal malfunctions. Second, to use a sheet metal laser cutting machine efficiently, one cannot focus solely on “cutting fast,” but must systematically optimize across six levels: equipment selection, process parameters, programming layout, operating habits, maintenance management, and automated collaboration.

Below is a practical and detailed sheet metal laser cutting machine usage guide suitable for daily production and cost reduction in sheet metal factories.

1. How to use a sheet metal laser cutting machine correctly?

1) 7 Essential Pre-Start Checks (Most Critical)

– Sheet Material:

Sheet material should be flat and free from severe warping. Surface should be free of oil stains, watermarks, and abnormal film application.

– Cutting Head:

Protective lens should be clean and free of burn marks. Nozzle should be free from deformation and have normal concentricity.

– Gas:

Correct gas type (oxygen/nitrogen/air). Stable pressure and no leaks.

– Cooling System:

Cooling water level should be normal. Water temperature should be within the set range (generally 22–26℃).

– Equipment Status:

Guide rail lubrication should be normal. No abnormal alarms.

– Safety Protection:

Safety door should be closed. Emergency stop button should function normally.

– Procedure:

Drawings, materials, and thicknesses should be confirmed to be correct.

2) Parameter Settings: Correctness is More Important Than Speed

- Basic Principles

- Don’t pursue maximum speed.

- Prioritize ensuring complete cut and stable cross-section.

- Parameter Logic

- Power ≠ The higher the better.

- Speed ≠ The faster the more efficient.

Focus is the core of stable cutting.

- Common Experience

- Thin plates: Slightly positive focus, faster speed.

- Thick plates: Slightly negative focus, slower speed.

- Many burrs → Reduce speed or increase air pressure.

- Incomplete cut → Adjust focus or increase power.

3) Programming and Cutting Sequence (Anti-deformation, Anti-collision)

- Internal holes first, then external shapes. Cut smaller contours first, larger contours last.

- Avoid heat concentration (cross-cutting). Properly set lead wire length and direction.

- Correct sequence reduces the risk of material warping and cutting head collision.

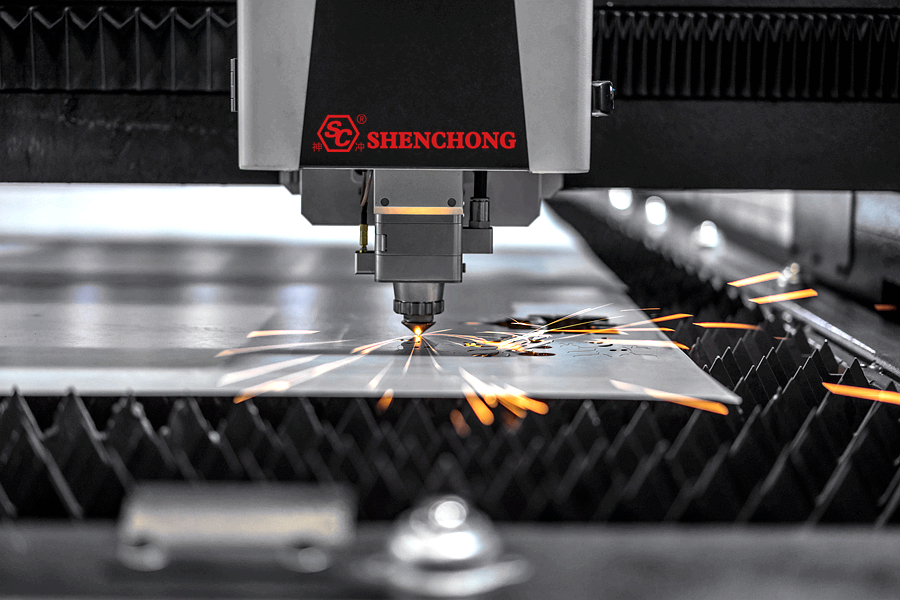

4) Correct Operation During Cutting

- Observe whether the spark is stable and vertical. Stop immediately if any abnormality is found (do not force a cut).

- Do not put your hands into the cutting area. After cutting, confirm that the cutting head has returned to the safe position.

5) Shutdown and Finishing Operations (Many people overlook this)

- Clean up waste from the cutting table.

- Turn off the laser.

- Turn off the gas supply. Shut down according to the procedure (do not directly disconnect the power).

- Record any abnormalities or parameter adjustments.

6) Common Sheet Metal Laser Cutting Machine Usage Errors (Must be avoided)

❌ Start cutting without confirming the material and program.

❌ Continue cutting if the lens is dirty.

❌ Force cutting while the material is warped.

❌ Adjust only the speed, not the focus.

❌ Reset alarms directly without handling them.

2. Techniques for Sheet Laser Cutting Machine Efficient Usage

Efficient Laser Cutting = Suitable Equipment + Correct Parameters + Efficient Layout + Standardized Operation + Stable Maintenance

1) Equipment and Configuration: Prerequisites for Efficiency

- Laser Power Matching Materials

Materials | Recommended power |

0.5–3 mm Carbon steel/stainless steel | 3–6 kW |

3–6 mm | 6–12 kW |

8–12 mm | ≥12 kW |

- Too low power = slow speed + rework

- Too high power = high energy consumption, thin boards are prone to overheating

- Essential Core Components

- Automatic focusing cutting head (capacitive)

- High-speed linear motor / high-acceleration drive

- Stable chiller (temperature control ±5℃)

- High-quality gas supply system (nitrogen/oxygen)

2) Cutting Process Parameters: Determine speed, cross-section, and stability

- Four Key Parameters Adjusted in Tandem

- Cutting speed

- Laser power

- Focal point position

- Assist gas type & pressure

Rules of thumb:

- Thin plates: High speed + Low power + Slightly positive focal point

- Thick plates: Low speed + High power + Slightly negative focal point

- Gas selection for different materials

Materials | Auxiliary gas | Features |

Carbon steel | Oxygen | Fast speed, low cost |

Stainless steel | Nitrogen | Bright white cut, no oxidation |

Aluminum plate | Nitrogen | Anti-oxidation, anti-slag |

3) Programming and Layout: Key to 20-40% Efficiency Improvement

- Efficient Layout Techniques

- Use Automatic Common-Edge Cutting

- Cluster Cutting of the Same Thickness/Material

- Reduce Idle Strokes and Blade Lifting Frequency

- Save 5-15% Material + 10-30% Time Per Board

- Cutting Path Optimization

- Inner Contour First, Outer Contour

- Small Hole → Large Hole → Outline

- Avoid Heat Concentration (Cross-cutting)

4) Operating Habits: The Difference Between "Expert vs. Ordinary Operators"

- Pre-Start Checklist (Mandatory)

- Is the lens clean?

- Nozzle concentricity

- Is the board flat?

- Is the gas pressure stable?

- Pre-Production Precautions

- Do not pursue extreme speeds

- Stop machine immediately and adjust parameters if splashing/slag appears

- Correct board warping or cut in sections

5) Maintenance and Care: Determines Long-Term Efficiency and Failure Rate

- Daily Maintenance

- Clean and protect the lens

- Clean cutting table debris

- Check air and water circuits

- Periodic maintenance

Item | Cycle |

Lens replacement | 1–3 months |

Coolant replacement | 3–6 months |

Railway lubrication | Weekly |

70% of cutting instability comes from lens contamination and abnormal cooling.

6) Automation and Process Optimization: A True "Efficiency Amplifier"

- Recommended Automation Configuration

- Automated Loading and Unloading System.

- Sheet Metal Storage System (Tower/Flat Library).

- Data Integration with Bending and Stamping Processes.

- Typical Efficiency Improvements

- Labor Costs Reduced by 50%.

- Equipment Utilization Rate Increased by 30–60%.

- Night Shift/Unmanned Production Becomes Possible.

7) Quick Reference Table for Common Inefficiency Issues

Phenomena | Causes | Countermeasures |

Incomplete cut | Incorrect focus / Insufficient power | Refocus or reduce speed |

Many burrs | Low air pressure / Excessive speed | Increase air pressure |

Slag buildup | Focus deviation | Fine-adjust focus |

Frequent machine downtime | Dirty lens | Clean immediately |

3. Summary

The key to efficient sheet metal laser cutting machine usage is not “blindly increasing speed,” but rather establishing a stable and high-yield system encompassing equipment, processes, programming, operation, and maintenance.

Fiber laser cutting machine efficiency = Suitable equipment × Correct process × Scientific programming × Stable maintenance × Automated collaboration

Six key points for efficient sheet metal laser cutting machine usage:

1) Choose the right equipment: Match power to material thickness; avoid waste on thin sheets and minimize strain on thick sheets.

2) Don’t arbitrarily adjust parameters: Speed, power, and focus must be coordinated; avoid pursuing extreme speeds for stability and faster results.

3) Layout is crucial: Use common-edge cutting to minimize idle runs, saving time and material per sheet.

4) Correct cutting sequence: Cut internal holes first, then external shapes, to prevent deformation and material breakage.

5) Standardized operation: Check the lens, nozzle, and air pressure before starting the machine; stop immediately if any abnormalities are found.

6) Don’t neglect maintenance: A clean lens and proper cooling are essential for consistent high speed.