Table of Contents

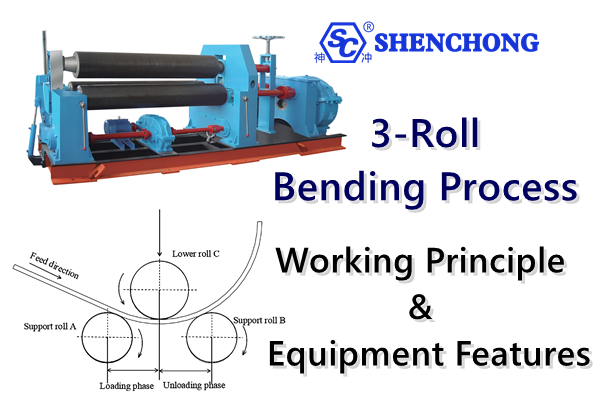

The three-roll bending machine are basic forming equipment used to roll metal sheets into cylinders, cones, or curved shapes. We’ve compiled the most common fault symptoms and corresponding maintenance points to facilitate operator prevention, rapid handling by maintenance personnel, and management by equipment supervisors.

Below is a list of common three-roll bending machine faults and maintenance countermeasures, presented in four levels: symptoms → causes → solutions → prevention. This is suitable for maintenance personnel to quickly troubleshoot, for workshop training, and for direct use as after-sales documentation.

1. Analysis of common faults and maintenance strategies

1) Three-roll Bending Machine Rolling Quality Defects

- Out-of-round/Oval Roll

Symptoms: One side of the cylinder is tight, the other loose. Repeated rounding is required after forming.

Causes: Three rollers are not parallel. The left and right side rollers are not synchronized. Insufficient pre-bending of the sheet material.

Solutions: Correct the parallelism of the upper and lower rollers. Adjust the synchronization valve or mechanical linkage. Increase the pre-bending stroke.

Prevention: Regularly perform roller system accuracy checks. Use fixed process parameters for materials of the same thickness.

- Sheet Material Deviation

Symptoms: The sheet material moves to one side. Uneven end faces.

Causes: Roller surface contamination or uneven wear. Inconsistent side roller stroke. Incorrect feeding.

Solutions: Clean the roller surface. Correct the side roller stroke. Recalibrate the feeding position.

Prevention: Clean the roller surface every shift. Correct the straightness of the sheet material before rolling.

- Sheet slippage

Symptom: Rollers rotate, but sheet doesn’t move. Material cannot be fed during the initial rolling stage.

Causes: Oil stains on the roller surface; insufficient pressure; material surface is too smooth.

Solutions: Clean the roller surface; appropriately increase the pressure; slightly roughen the roller surface if necessary.

Prevention: Do not directly roll oil-stained sheets; set appropriate pre-bending pressure.

2) Hydraulic System Failure

- Insufficient System Pressure

Symptoms: Rollers cannot be pressed down; set thickness cannot be achieved.

Causes: Insufficient hydraulic oil; pump wear; relief valve depressurization.

Solutions: Add hydraulic oil; repair or replace the oil pump; readjust or replace the relief valve.

Prevention: Maintain oil level; regularly check system pressure.

- Overheating Oil

Symptoms: Oil tank is hot to the touch; sluggish operation.

Causes: Clogged filter element; continuous high-load operation; deteriorated oil quality.

Solutions: Replace the filter element; stop the machine to cool down; replace the hydraulic oil.

Prevention: Control continuous working time; regularly maintain the filtration system.

- Asynchronous Operation

Symptoms: Uneven stroke of left and right side rollers; skewed winding.

Causes: Malfunctioning synchronization valve; blocked oil circuit; loose mechanical connection.

Solutions: Clean or replace the synchronization valve; bleed air and clean the oil circuit; tighten mechanical connections.

Prevention: Keep the oil clean; regularly perform synchronization calibration.

3) Mechanical Transmission Failure

- Asynchronous Operation

Symptoms: Knocking sound during operation; machine shaking

Causes: Insufficient or damaged bearings; worn gears; loose bolts

Solutions: Lubricate immediately or replace bearings; inspect gears; tighten all fasteners

Prevention: Lubricate periodically; regularly check for tightness

- Main Roller Rotation Difficulty

Symptoms: Difficulty starting; uneven speed

Causes: Damaged bearings; high transmission resistance; misaligned coupling

Solutions: Replace bearings; correct transmission system; align coupling

Prevention: Regularly check temperature rise and vibration

4) Electrical and Control Faults

- Motor Does Not Start

Symptoms: No response when starting

Causes: Emergency stop not reset; Overload protection activated; Power phase loss

Solutions: Check emergency stop; Reset protection; Check power supply

Prevention: Test emergency stop every shift; Regularly check electrical system

- Control Malfunction/False Action

Symptoms: Buttons ineffective; Abnormal travel

Causes: Damaged limit switch; Loose wiring; Aging control components

Solutions: Replace limit switch; Tighten wiring; Replace aging components

Prevention: Regularly test functionality; Keep electrical cabinet clean

5) Sealing and Leakage Faults

- Hydraulic Oil Leakage

Symptoms: Oil seepage from cylinder and joints; Oil stains on the floor

Causes: Aging seals; Loose joints; Damaged oil pipes

Solutions: Replace seals; Tighten or replace oil pipes

Prevention: Regularly replace seals; Avoid high-temperature operation

2. Quick Troubleshooting Approach

First check the oil level, then listen for sounds.

For out-of-roundness, check the rollers.

For synchronization issues, check the valves.

For oil leaks, check the seals; for unusual noises, check the shaft.

If the power doesn’t work, immediately stop the three-roller plate bending machine.

3. Troubleshooting Red Lines

❌ Continuing production with a fault

❌ Frequent forced resets

❌ Unauthorized increases in system pressure

❌ Ignoring oil temperature and unusual noises

❌ Disabling safety devices

4. Quick Troubleshooting Table for Three-Roll Bending Machine

1) Rolling quality

Fault Symptoms | Quickly identify the following issues | Main reason | Troubleshooting measures |

Out of round roll / elliptical | Inconsistent left and right dimensions | Roller misalignment / poor synchronization | Correct roller parallelism and adjust synchronization. |

Cylindrical/conical shape | One end is tight, the other is loose | Uneven side roller stroke | Correct side roller stroke |

Sheet material misalignment | The board moves to one side | Dirty roller surface / Misaligned feed | Clean roller surface and correct feed |

Sheet material slippage | The roller does not move the board | Insufficient pressure / Oil on roller surface | Increase reduction and clean roller surface |

Surface damage | There are marks on the surface | Foreign matter on roller surface | Stop for cleaning and grinding |

2) Hydraulic systems

Fault symptoms | Quickly determine point | Main reason | Countermeasures |

Insufficient pressure | Roller cannot be pressed down | Low oil level/Pump wear | Add oil, inspect oil pump |

Pressure fluctuation | Indicator needle jumps | Valve core contamination | Clean valve assembly |

Excessively high oil temperature | Oil tank is hot to the touch | Filter element blockage/Overload | Replace filter element, shut down and cool down |

Slow operation | Slow response | Deteriorating oil quality | Change hydraulic oil |

Left and right asynchrony | Inconsistent stroke | Synchronization valve malfunction | Adjust or replace synchronization valve |

3) Mechanical transmission

Fault symptoms | Quickly determine point | Main reason | Countermeasures |

Abnormal noise | Tapping/Screaming | Insufficient bearing lubrication | Immediate lubrication |

Excessive vibration | Overall vibration | Loose bolts | Fully tightening |

Main roller rotation is not smooth | Difficulty starting | Damaged bearing | Replace bearing |

Uneven speed | Variations in speed | Eccentric coupling | Alignment adjustment |

4) Electrical And Control Engineering

Fault symptoms | Quickly determine point | Main reason | Countermeasures |

Motor does not start | No response | Emergency stop failed to reset | Reset emergency stop |

Trips immediately upon startup | Overload alarm | Overload | Load reduction check |

Control malfunction | Buttons unresponsive | Limit switch damaged | Replace limit switch |

False action | Abnormal travel | Loose wiring | Check wiring |

5) Leakage and sealing

Fault symptoms | Quickly determine point | Main reason | Countermeasures |

Oil leak from hydraulic cylinder | Oil dripping from rod end | Sealing aging | Replace seal |

Oil leak from pipeline | Oil stains on joint | Loose joints | Tighten or replace |

Oil stains on the floor | Continuous oil dripping | Ruptured oil pipe | Replace oil pipe |

5. Troubleshooting Flowchart for Three-Roll Bending Machine Maintenance Personnel (Standard Version)

First: Equipment Abnormality Detected / Operator Reports Fault

Step 1|Safety Confirmation First (Mandatory Step)

Is the emergency stop button pressed?

Is the equipment unloaded?

Is the plate completely detached?

Repair tag / Power off confirmation

✅ Safety Confirmation Completed → Proceed to Step 2

❌ Incomplete → Troubleshooting Prohibited

Step 2|Quick Classification and Judgment (Complete within 30 seconds)

Ask yourself 3 questions:

- Is it not moving?

- Is it moving but abnormal?

- Is it able to move but not rolling properly?

Corresponding to different branches

【Branch A】Equipment not operating / not starting

A1: Check electrical (priority)

Is the emergency stop reset?

Is there a phase loss in the power supply?

Is the overload protection tripped?

- Normal → A2

- Abnormal → Test run after handling

A2: Check control

Is the start button sending a signal?

Is the contactor engaging?

Is the PLC/controller alarming?

- Normal → A3

- Abnormal → Repair the control circuit

A3|Check hydraulic starting conditions

Is the hydraulic pump starting?

Is the oil level too low?

- Normal → Proceed to Step 3

- Abnormal → Add oil / Repair the pump

【Branch B】3-roll plate bending equipment operating abnormally (slow, jerking, out of sync)

B1|Check hydraulics first (80% of the problems are here)

Is the oil level / oil quality

Is the pressure gauge stable?

Is the oil temperature too high?

- Abnormal → Change the oil / Change the filter

- Normal → B2

B2|Check synchronization

Is the stroke of the left and right side rollers consistent?

Is the synchronization valve stuck?

- Abnormal → Clean / Adjust the synchronization valve

- Normal → B3

B3|Check Machinery

Is there any abnormal noise from the bearings? Is the coupling eccentric? Are the bolts loose?

After handling → Test run

【Branch C】Works but poor rolling quality

C1|Check Roller System (First Focus)

Are the three rollers parallel? Is there any oil or pressure marks on the roller surface?

- Abnormal → Correct/Clean

- Normal → C2

C2|Check Process Parameters

Is the pressing amount insufficient? Is the pre-bending in place?

- Adjust parameters → Test roll

- Still abnormal → C3

C3|Check Material Factors

Is the sheet metal bent? Are the material and thickness outside the range?

- Material problem → Replace material

- Troubleshooting → Go to Branch B for re-inspection

Step 3|Verification after troubleshooting

No-load test run

Low-load test roll

Normal load production

- ✅ Stable continuous operation → End

- ❌ Still abnormal → Return to Step 2

Step 4 | Record Keeping and Prevention (Required)

Complete the “Fault Repair Record”

Note:

- Cause of Fault

- Replaced Components

- Adjusted Parameters

Determine if necessary:

- Included in Regular Maintenance

- Adjusted Operating Procedures

6. Summary

80% of three-roll bending machine malfunctions stem from inadequate maintenance.

- Out of round, unstable → Mostly due to roller system and synchronization issues.

- No movement, weak power → First check oil level, pressure, and electrical systems.

- Abnormal noise, vibration → Inadequate bearing lubrication and tightening.

- High oil temperature, slow operation → Poor oil quality, clogged filter.

Maintenance focuses on 5 key aspects: Oil, Rollers, Shafts, Valves, Safety.

Maintenance focuses on 5 crucial points (preventing malfunctions):

Key Points | Maintenance Procedures |

Oil | Check oil level, replace filter, control oil temperature |

Roller | Clean, calibrate (avoid forceful hammering) |

Shaft | Lubricate bearings, check for abnormal noises |

Valve | Keep oil clean |

Safety | Periodic testing of emergency stop and limit switches |

Implement these 3 habits:

- Check oil and clean rollers before shift

- Stop immediately if there are abnormal noises or oil leaks

- Regularly calibrate and change oil.