Table of Contents

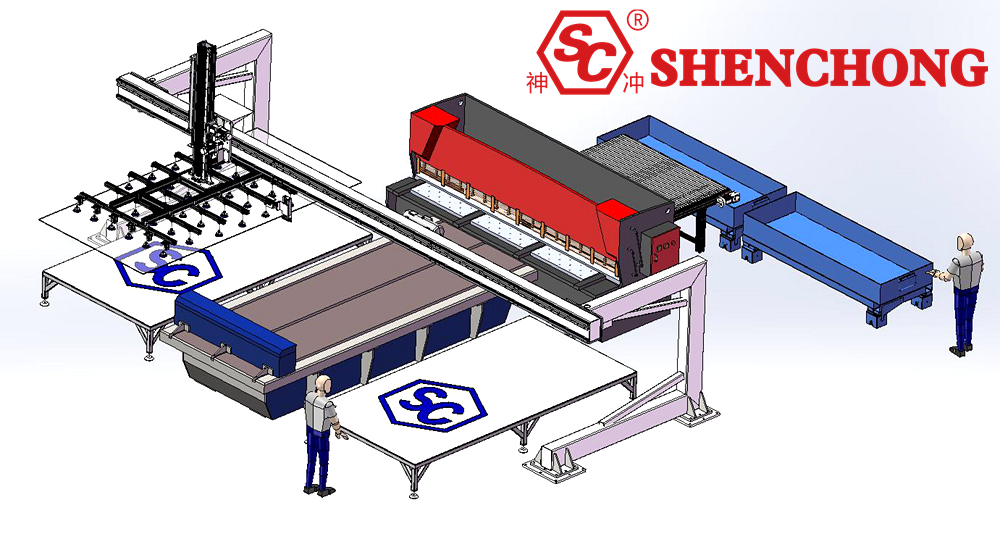

Shearing automation refers to a fully automated or minimally manned production process achieved by equipping traditional shearing machines with automated units at both the front and rear ends, enabling automatic feeding, alignment and positioning, shearing, and stacking/unloading of sheet metal.

Common automated units include:

- Gantry/Articulated Robot Loading and Unloading Systems

- Automatic Loading Racks (Stacking Loaders)

- Automatic Feeding Platforms

- Rear-End Automatic Receiving and Stacking Devices

- Intelligent Sheet Storage Linkage System

1. Six Major Advantages of Sheet Metal Shearing Automation

1) Significantly Improved Production Efficiency

Traditional shearing machine operation requires manual handling and alignment, resulting in inconsistent efficiency.

Automation:

- Continuous production with no downtime

- High positioning accuracy, reducing repetitive alignment actions

- Can be linked with upstream material warehouses or laser cutting systems for cycle-based production

- Efficiency increase: 30%–150% (depending on configuration)

2) Reduced Labor Intensity and Safety Risks

Manual handling of steel plates presents risks:

- High load (heavy steel plate weight)

- Risk of sharp edge cuts

- Risk of hand pinching/crushing

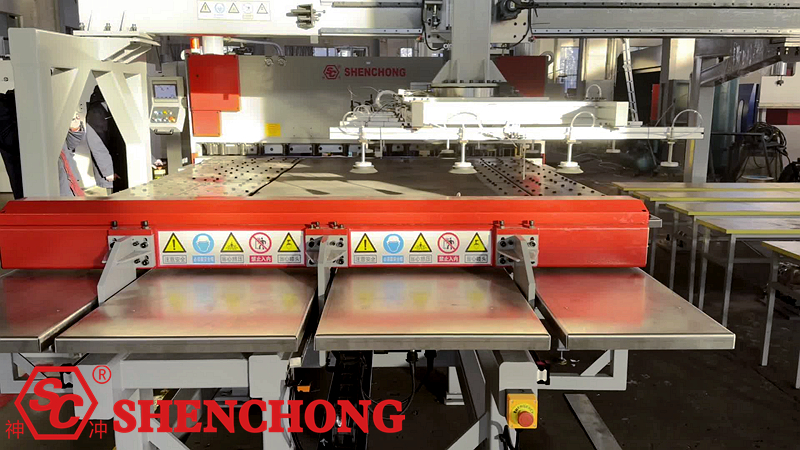

Automated solutions utilize suction cups, clamps, pallets, and other conveying methods.

Completely isolates personnel from hazardous areas, meeting ISO/CE safety standards.

A key component in factory acceptance for Smart Manufacturing/Digital Factory certification.

3) Significantly Improved Shearing Accuracy and Consistency

Automatic clamping and positioning fixtures ensure that each piece of material has:

- Stable edge reference

- High consistency in shearing dimensions (±2~0.5 mm, depending on shearing machine performance)

- Error is independent of worker skill

Especially suitable for enterprises engaged in multi-size repetitive processing and mass production.

4) Continuous and Stable High-Cycle Operation

The automated shearing system supports:

- Uninterrupted material supply

- 24-hour continuous operation

- Equipment utilization rate from 40% → 85%+

The value advantage of automation is even more pronounced in three-shift/two-shift factories.

5) Reduced Overall Costs (Most Significant Long-Term ROI)

Although the initial investment in automation is high (200,000–800,000 RMB depending on configuration),

long-term costs can be significantly reduced:

- Reduced labor costs

- Reduce costs associated with workplace injuries

- Reduce scrap rates and rework

- Increase output per square meter (saving factory space)

Typically, the return on investment can be achieved in 1–2 years (depending on sheet production and labor costs).

6) Integration with Digital Systems (Towards Smart Factories)

Automation systems typically support integration with systems such as MES/WMS to achieve:

- Batch traceability of sheet metal

- Automatic invocation of shearing tasks

- Automatic transmission of shearing data

- Automatic material feeding with smart material warehouses

This is the core of the manufacturing industry’s transition to lean production/smart manufacturing equipment.

2. Typical Application Scenarios of Automated Shearing (Industry Analysis)

Shearing automation is mainly used in industries that require large-scale, stable, and highly efficient shearing of sheet metal.

- Sheet Metal Processing Plants (OEM/ODM)

Large quantities of repetitive sheet metal → Automated shearing lines are most suitable.

Examples:

- Air conditioning sheet metal

- Distribution boxes

- Chassis and cabinets

- Home appliance sheet metal

Automated production lines can be formed, performing laser cutting → shearing → bending → welding.

- Construction and Steel Structure Processing

Long-term need for cutting long, wide, and thick plates:

- Color steel plate production

- building envelope systems

- steel structure factories

- steel trading shearing centers.

Automation can significantly save manual handling and positioning time.

- Automotive Parts Industry

Highly demanding product consistency requirements; suitable for automated feeding and online inspection.

Common examples:

- Automotive chassis parts

- Pre-stamping shearing,

- Sheet metal cutting before thermoforming

- Wind Power, Pressure Vessel, and Boiler Manufacturing

These industries commonly use large, thick plates, which are difficult to handle and pose significant safety risks. Automated shearing can greatly reduce manpower and risk.

- Stainless steel processing for furniture, kitchenware...

Requires high consistency in appearance; manual handling easily scratches the surface. An automatic adsorption + anti-scratch system protects the surface and improves quality.

3. Suitable Enterprises for Shearing Automation (Judgment Criteria)

- High daily shearing volume (>5 tons/day)

- Labor shortage/unstable skilled workers

- Repetitive batch production of sheet materials

- Large or thick sheets, difficult to handle manually

- Need to improve product consistency and traceability

- Want to improve production management through intelligent systems

4. Common Configurations for Shearing Automation (Reference)

1) Automatic Feeding System

- Stacking feeder (vacuum suction cup)

- Intelligent material storage docking with automatic feeding

- Magnetic/vacuum sheet separating mechanism

2) Feeding and Positioning System

- Electric servo feeding table

- Automatic reference edge positioning fixture

- Laser-assisted positioning

3) Automatic Back-end Unloading and Palletizing

- Automatic conveyor belt

- Servo pusher platform

- Automatic palletizing robot or gantry

4) Software System

- Shearing program layout

- MES/ERP linkage

- Order management and traceability

Industry Comparison Table for Shearing Automation Applications:

Industry Categories | Typical Application Scenarios | Key Values of Automation |

Sheet Metal Processing (Racks, Chassis, Home Appliance Sheet Metal) | Bulk shearing of sheet metal with fixed specifications | Improved cycle time, guaranteed dimensional consistency, reduced manual labor |

Steel Structure / Construction Industry | Shearing of color steel sheets, curtain wall panels, and structural components | Enhanced safety and efficiency in large panel handling |

Automotive Parts Manufacturing | Shearing of sheet metal panels and chassis components before stamping | High-precision requirements, automation improves consistency |

Pressure Vessels / Boilers / Wind Power Manufacturing | Shearing of thick plates and large-size sheet metal | Reduced labor intensity, improved precision and safety |

Stainless Steel Kitchenware / Home Furnishings Industry | Shearing of countertops, kitchen cabinets, and stainless steel sheets | Better scratch resistance, improved appearance quality |

Steel Processing and Distribution Center (Shearing Center) | Bulk processing and delivery of sheet metal of various specifications | High efficiency, rapid processing of multiple batches of orders |

Machinery Manufacturing Industry | Pre-processing of sheet metal components and structural parts | Stable continuous production, reduced reliance on manual labor |

Elevator Manufacturing Industry | Shearing of car panels and sheet metal sheet metal panels | Guaranteed panel dimensional consistency, improved quality stability |

5. Why Choose Shearing Automation?

- Significantly Improved Production Efficiency

Automated feeding, precise positioning, and rapid shearing enable continuous operation throughout the entire process, increasing capacity by 30-150%.

- Reduced Labor and Safety Risks

Eliminates the need for manual handling of heavy plates, avoiding risks such as scratches and pinching, creating a safer production environment.

- Higher and More Stable Shearing Precision

Automatic baseline positioning ensures excellent dimensional consistency, meeting the demands of high-standard mass production.

- Reduced Overall Production Costs

Reduced labor input and scrap rate; the system is stable and reliable, typically achieving cost recovery within 1-2 years.

- Support for Digital and Unmanned Factories

Can be integrated with smart warehouses and MES systems to achieve order scheduling, production traceability, and intelligent production scheduling.

6. Conclusion: Value Summary of Metal Shearing Automation

Shearing automation is not merely an equipment upgrade to improve shearing efficiency. It is also one of the core pieces of equipment for manufacturing plants moving towards digitalization, lean manufacturing, and unmanned operation.

Its comprehensive value includes:

- Faster production capacity

- Higher product stability

- Lower labor and management costs

- Safer work environment

- Stronger digital capabilities

Suitable for large-scale sheet metal processing scenarios in medium to large-sized sheet metal manufacturing enterprises.

Shearing automation adds automatic feeding, automatic positioning, and automatic unloading systems before and after traditional shearing machines, making the shearing process less reliant on manual labor, more efficient, and safer.

Core Advantages:

- Higher Efficiency: Continuous operation, no downtime.

- Safer: Avoids manual handling of heavy plates.

- More Stable Quality: Automatic positioning ensures more consistent dimensions.

- Saving Labor and Costs: Investment can be recovered in 1-2 years.

Main Applications:

Sheet metal processing plants, steel structures, automotive parts, stainless steel kitchenware, pressure vessels, and other industries requiring large-scale sheet metal shearing.