Table of Contents

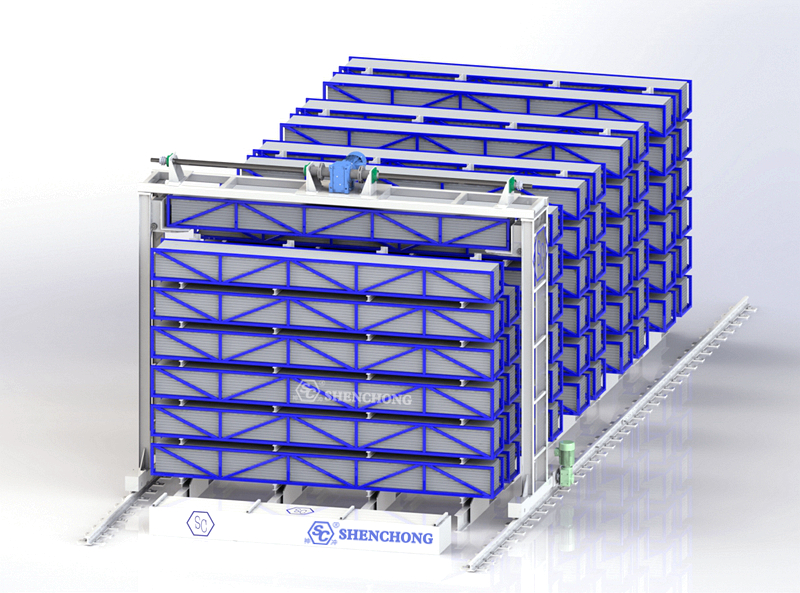

SC Automatic Gantry Profile Storage System is an intelligent three-dimensional storage and automatic material handling system specifically designed for the steel structure, sheet metal processing, and profile manufacturing industries.

Through a gantry-type traveling mechanism and multi-level material handling, it achieves automatic storage, precise positioning, unmanned material handling, and efficient outbound processing of profiles, comprehensively improving warehouse utilization and logistics efficiency.

1. Gantry Profile Storage System Definition

The gantry-type automated profile storage system is an intelligent three-dimensional storage device with a gantry traveling mechanism as its core execution unit. It is specifically designed for the automatic storage, management, and scheduling of long, heavy-duty profiles (such as H-beams, I-beams, channel steel, angle steel, and pipes).

Through automatic identification, precise positioning, and programmed control, the system achieves automatic warehousing, storage, material handling, and outbound processing of profiles, connecting with production lines. It is a crucial foundational equipment for modern steel structure and heavy manufacturing enterprises to achieve automated warehousing and continuous production.

Main Components:

- Gantry-type traveling mechanism (high rigidity, high load-bearing capacity).

- Multi-layer profile storage rack.

- Automatic material handling device (forklift/clamp type).

- Roller conveyor or chain conveyor system.

- PLC control system + WMS management software.

Gantry Profile Storage System Technical Features:

- Suitable for storing extra-long and heavy-duty profiles.

- Mixed storage of profiles of various specifications.

- Automatic storage and retrieval with precise positioning.

- Capable of continuous 24-hour operation.

- Easy to expand, easy to maintain, and customizable.

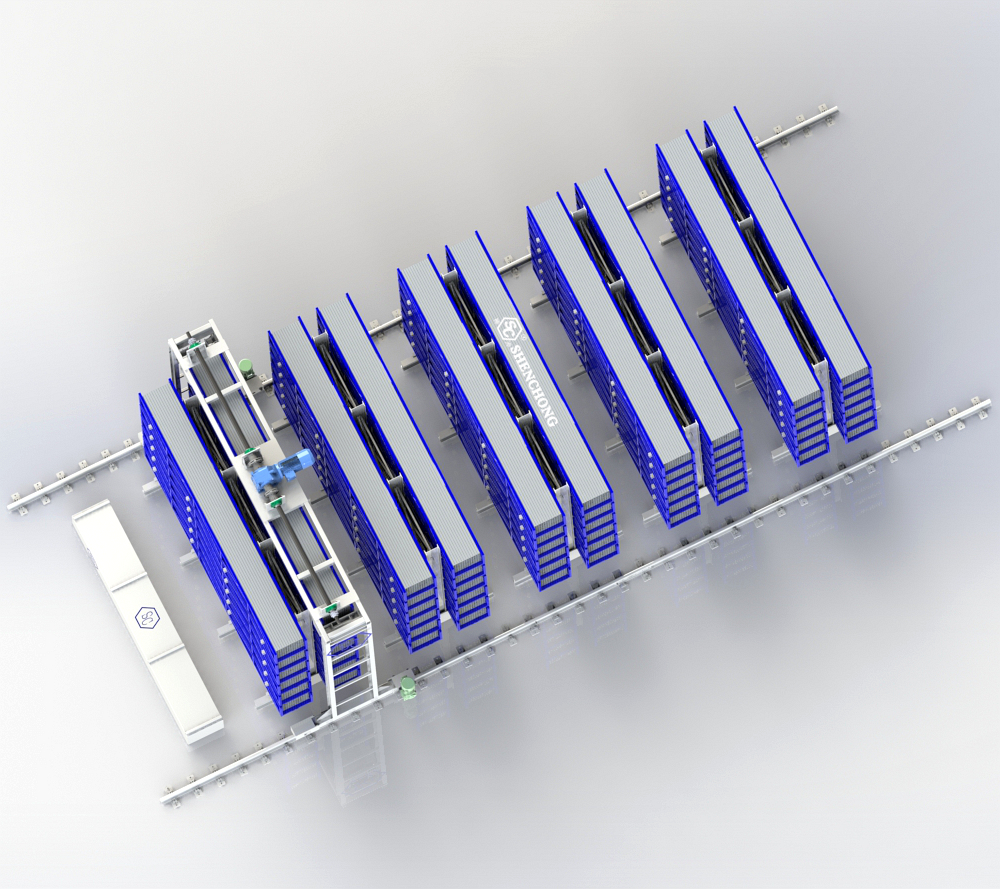

2. Automatic Gantry Profile Storage System Overall Structure Composition

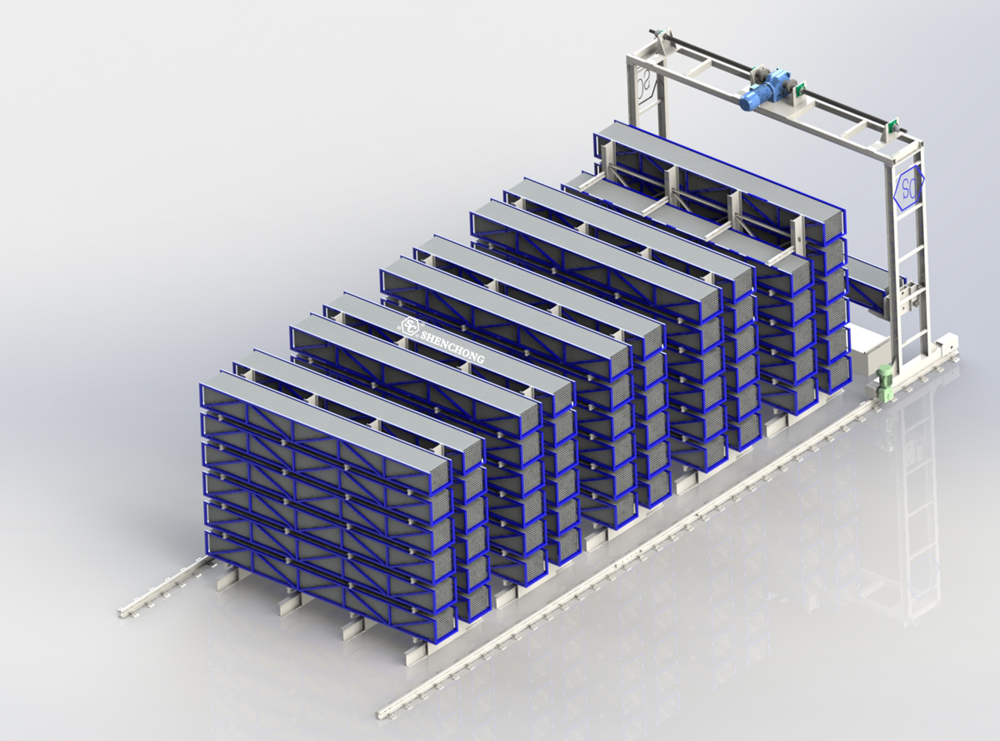

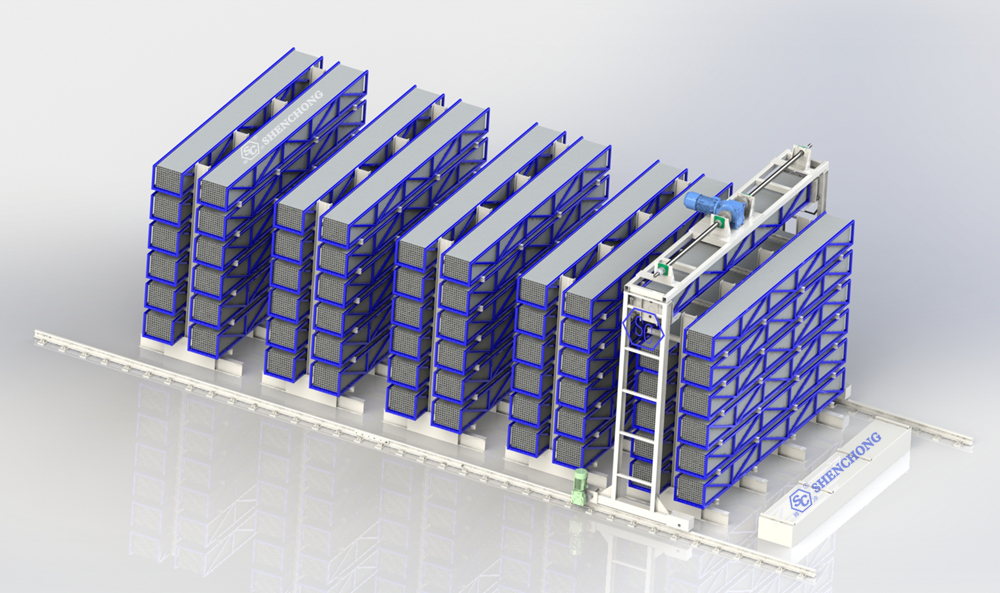

1) Gantry-type Walking Mechanism (Core Execution Unit)

- Double column + beam structure, high overall rigidity, stable operation.

- Servo-driven or frequency conversion-driven walking system.

- X/Y/Z three-axis or multi-axis linkage for precise picking and placing.

- Suitable for high-speed handling of ultra-long and ultra-heavy materials.

Features: High load-bearing capacity, high positioning accuracy, suitable for high-frequency operations

2) Three-dimensional Profile Storage Rack System

- Multi-layer, multi-row material storage design.

- Supports mixed storage of different specifications.

- Single layer can accommodate multiple profiles or bundles.

- Load capacity can be customized from 1–5 tons/layer.

Function: Maximizes the use of factory height and improves space utilization

3) Profile Picking Device

Configured according to profile type and weight:

- Forklift picking

- Clamping picking

- Adsorption + Mechanical clamping composite material handling (lightweight pipes)

Advantages: Anti-slip, anti-deformation, ensuring profile surface and straightness

4) Conveying and docking system

- Roller conveyor line

- Chain conveyor line

- Dock sawing line, drilling line, welding line, or manual workstation

Achieves: Automatic closed loop of warehousing → processing → return to warehouse

5) Electrical control and software system

- PLC + servo control system

- Human machine interface (HMI)

- Profile warehouse management software (WMS)

- Supports integration with ERP/MES

Functions:

- Automatic scheduling

- Real-time inventory management

- Prevention of incorrect materials and incorrect retrieval

- Data traceability

3. Gantry-type Automatic Profile Storage System Working Principle

1) Automated Inbound Process

- The profiles enter the inbound station via the feeding roller conveyor.

- The system automatically identifies the profile specifications, length, and weight.

- The WMS allocates the optimal storage location.

- The gantry mechanism picks up the material and stores it in the designated location.

2) Automatic Outbound Process

- The production system or a person issues an outbound command.

- The system automatically locates the target profile.

- The gantry mechanism accurately picks up the material.

- The profile is conveyed to downstream processing equipment or the outbound area.

4. Key Technical Features and Advantages

- High Load Capacity & High Stability

- Suitable for heavy-duty profiles (single profile can weigh hundreds of kilograms or more).

- Structurally resistant to torsion and vibration, ensuring smooth operation.

- High Efficiency & Continuous Operation

- Automatic scheduling reduces waiting time.

- Supports 24-hour continuous operation.

- High Flexibility & Strong Adaptability

- Multiple profile specifications can be stored together.

- Expandable storage locations and channels.

- High Safety & Low Risk

- Multiple anti-collision and anti-drop protections.

- Reduces accidents caused by manual handling.

5. Typical Technical Parameters

Parameter Example Table:

Project | Parameter range |

Profile Length | 6–12 m (customizable) |

Single Layer Load Capacity | 1–5 tons |

Number of Storage Layers | 5–15 layers |

Positioning Accuracy | ±2–5 mm |

Control Method | PLC + Servo |

System Integration | ERP / MES / Production Line |

6. Typical Application Scenarios

- Steel structure production line front-end profile buffer.

- Engineering machinery structural component processing workshop.

- Large profile centralized storage center.

- Supporting automated sawing and drilling production lines.

7. Selection and Configuration Recommendations (Practical)

When selecting a gantry-type profile storage system, the following should be considered:

- Maximum profile length and weight

- Profile specifications and mixed storage ratio

- Daily inbound/outbound frequency and cycle time

- Whether it connects to an automated processing line

- Factory height, span, and foundation conditions

8. Summary

The automatic gantry profile storage system is not only a warehouse but also part of the production line. This intelligent automated storage system is designed specifically for long, heavy-duty profiles. It integrates automatic storage, precise material retrieval, and intelligent scheduling, and can be linked with various processing production lines to achieve integrated operation of warehousing and production.

Through a highly integrated mechanical structure and intelligent control system, it helps enterprises achieve:

- Maximized storage space utilization

- Synchronization of logistics efficiency and production cycle time

- Reduced labor costs and safety risks

- Digitalization and transparency of the manufacturing process

- High-efficiency three-dimensional storage, freeing up factory space

The gantry automated profile storage system adopts a three-dimensional, multi-level material storage design, making full use of factory height to achieve centralized and orderly storage of profiles.

The system can simultaneously store various specifications of H-beams, I-beams, channel steel, angle steel, and pipes. Compared to traditional ground stacking, storage capacity is increased by 2-5 times, resulting in a cleaner, more organized, and more efficient warehouse.

- Automated Storage and Retrieval for Enhanced Production Efficiency

Through a gantry crane and intelligent material handling devices, the system automatically completes the warehousing, retrieval, and transportation of profiles, seamlessly integrating with production equipment such as sawing, drilling, and machining centers.

This enables minimally staffed or unmanned operations, significantly reducing manual handling intensity and waiting time, and improving warehousing efficiency and production continuity.

- Intelligent Management System for Digital Factories

The gantry profile storage system is equipped with profile warehouse management software (WMS), supporting real-time inventory monitoring, automatic scheduling, and data traceability, and can interface with ERP/MES systems.

This upgrades warehousing from “passive storage” to an intelligent buffer unit for the production line, providing a solid foundation for enterprise digital and intelligent upgrades.