Table of Contents

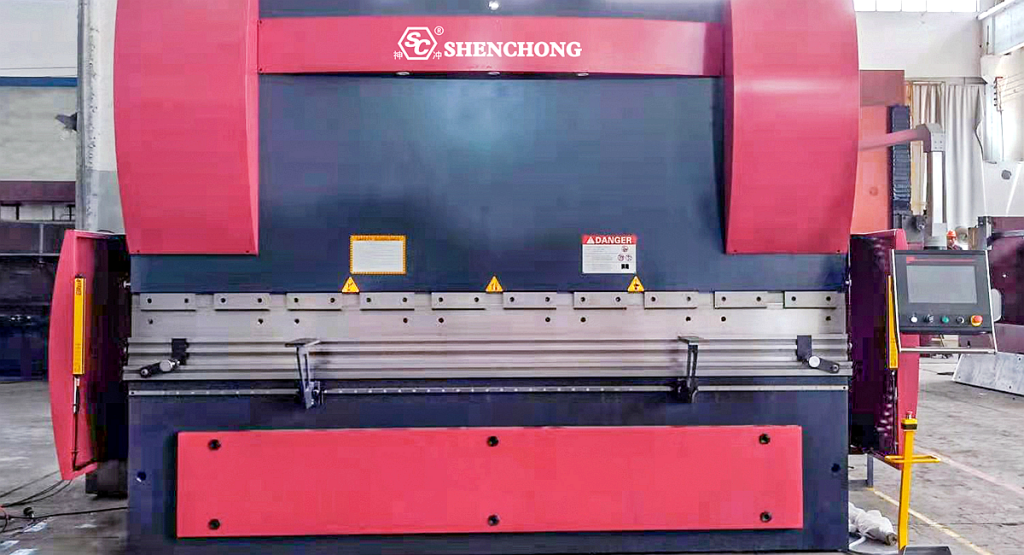

Canada CNC press brake 300tons 4000mm is a common medium and large equipment in the sheet metal processing industry. It is suitable for high-precision bending of medium and thick plates and is widely used in electrical cabinets, steel structures, machinery manufacturing, architectural decoration and other industries.

1. Introduction to Canada CNC press brake 300T 4000mm

300T 4000mm ESA640 4+1 axis CNC press brake machine is a high-performance electro-hydraulic bending equipment, which is widely used in sheet metal processing, machinery manufacturing, automotive parts and other fields.

Canada CNC press brake technical parameter table:

Parameters | Description |

Nominal pressure | 300 tons (3000kN) |

Bending length | 4000mm |

Number of axes | 4+1 axis (Y1, Y2, X, R + V) |

Slider stroke | 200mm |

Throat depth | 400mm |

Opening height | 400mm |

Main motor power | 18.5kW |

Control system | ESA640 high-end CNC system (ESA, Italy) |

2. Structure & Configuration Highlights

- Electro-hydraulic servo system: A closed-loop electro-hydraulic servo control system is used to ensure high synchronization accuracy of the slider, and the repeat positioning accuracy can reach ±0.01 mm.

- Workbench deflection compensation: Equipped with a V-axis hydraulic deflection compensation system, it automatically adjusts the deformation of the workbench to ensure bending accuracy.

- High-precision backgauge system: Both the X and R axes are driven by servo motors, with high positioning accuracy, which can meet the needs of various workpieces.

- Safety protection system: Optional laser safety protection device can be used to ensure the safety of operators.

- Modular design: The whole machine adopts modular design, which is easy to maintain and upgrade.

3. Structural and performance advantages

- Electro-hydraulic servo drive, energy-saving and efficient, low noise, simple maintenance.

- High-rigidity body, welded and precisely processed with high-quality steel, ensures machine stability and processing accuracy.

- High-precision backgauge system, fast positioning, improves processing efficiency.

- V-axis deflection compensation, effectively offsets deformation during large-format bending, and improves bending accuracy.

4. ESA S640 CNC system

- ESA S640 is a high-end CNC system launched by ESA, Italy, supporting multi-axis control and graphical programming, with the following features:

- Multi-axis control capability: supports 4+1 axis (Y1, Y2, X, R + V axis) control to meet complex bending process requirements.

- Graphical programming interface: equipped with a large-size touch screen, supports 2D/3D graphical programming, intuitive operation, and easy to use.

- Bending sequence simulation: bending sequence simulation can be performed to avoid interference and improve processing efficiency.

- Automatic angle compensation: Automatically calculate and adjust the bending angle according to the material and mold parameters to ensure processing accuracy.

- Multi-language support: Support multiple language interfaces to meet the needs of users in different regions.

5. Configuration and requirements suitable for the Canadian market

- All electrical components are UL certified products, which comply with Canadian and American electrical safety standards (UL/CSA certification).

- The control cabinet design complies with UL508A standards to ensure electrical safety.

- Equipped with emergency stop buttons and multiple safety protection devices (such as safety light curtains), in line with Canadian occupational health and safety standards (OSHA).

- The voltage standard is adapted to the 480V/60Hz three-phase power supply commonly used in North America.

- Use UL-certified cables, circuit breakers, contactors and other components to ensure long-term safe and stable operation.

If you need to know more about the price, configuration selection or compatible molds of this model, please provide your specific needs, and I will provide you with more detailed advice and support.