Table of Contents

A CNC plate shearing machine is a machine tool that uses a hydraulic system and a CNC control system to perform linear shearing of metal sheets. The CNC system precisely controls the back gauge position, shearing frequency, and work cycle to achieve high efficiency and consistency in sheet metal blanking. It is commonly used as the first step in the blanking process of sheet metal processing.

How to operate a shearing machine? Below is a comprehensive and detailed CNC shearing machine operation guide.

1. Shearing Machine Introduction And Application

CNC Shearing Machine Overview:

A CNC shearing machine is a specialized piece of equipment that utilizes a hydraulic system and a CNC control system to perform high-precision linear shearing of metal sheets. The equipment features high efficiency, stable shearing quality, simple operation, and high repeatability, and is widely used in sheet metal processing, chassis and cabinet manufacturing, steel structures, elevators, and machinery manufacturing industries.

The CNC shearing machine is mainly used for linear shearing of metal sheets such as steel plates, stainless steel, and aluminum plates.

Features include:

- CNC back gauge positioning

- Adjustable shearing angle (some models)

- Adjustable shearing gap

- High efficiency and high repeatability

Application:

Materials:

- Carbon steel, stainless steel, aluminum plates, galvanized plates

- Plate thickness: Based on the equipment’s rated parameters

- Plate width: Not exceeding the machine’s effective shearing width

Industries:

- Sheet metal processing plants

- Chassis and cabinet manufacturing, elevator manufacturing

- Steel structures, construction machinery

- Machinery manufacturing, hardware processing

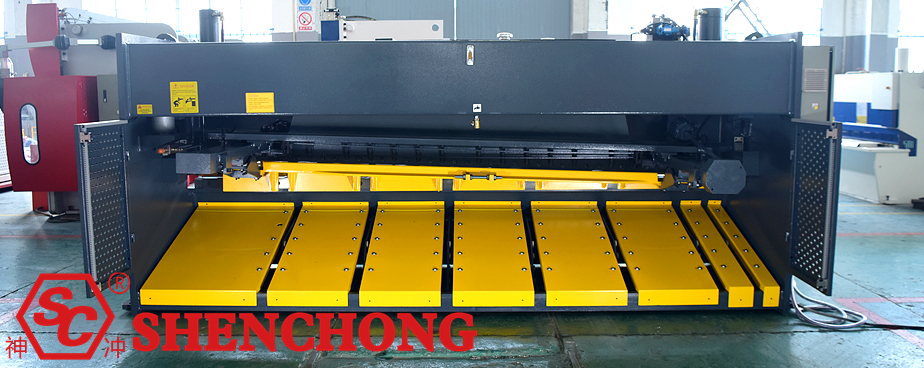

2. Main Structure and Function Description

1) Machine Body Structure

- Welded steel frame, stress-relieved

- High rigidity and shearing stability

2) Shearing System

- Upper and lower blade structure

- High-strength alloy blades, multi-faceted application

- Adjustable shearing gap

3) Hydraulic System

- Provides stable shearing power

- Equipped with pressure regulation and overflow protection devices

- Ensures smooth blade drop without impact

4) CNC System

- Controls back gauge positioning

- Counts shearing cycles

- Supports single/continuous shearing

5) Back Gauge Device

- Servo or stepper motor drive

- High-precision lead screw guidance

- High positioning accuracy and repeatability

6) Safety Protection System

- Front protective baffle

- Emergency stop button

- Travel limit protection

3. Safety Precautions (Must Be Followed)

Before the CNC shearing machine operation start, please carefully read this section:

- Operators must be professionally trained.

- It is strictly forbidden to use the equipment beyond its specifications.

- It is strictly forbidden to put your hands into the blade area during shearing.

- The machine must not be started if the protective device is not installed.

- If the equipment malfunctions, it must be stopped immediately for inspection.

- The main power supply must be disconnected before maintenance or blade replacement.

4. Pre-CNC Shearing Machine Operation Preparations (Must Be Performed)

1) Environmental and Personnel Inspection

Personnel Requirements:

- Operators must be trained and familiar with the equipment structure and operating procedures.

- Wear necessary personal protective equipment: cut-resistant gloves, protective shoes, and goggles if necessary.

Environmental Inspection:

- The area around the equipment is free of debris, and the ground is dry and non-slip.

- The workbench and shearing area are clean and free of residual iron filings.

- Sufficient lighting is provided for easy observation of the scale and shearing status.

2) Equipment Status Inspection (Before Start-up)

Checklist:

Inspection Items | Requirements |

Hydraulic Oil | Oil level above 2/3 |

Power Supply | Stable voltage, good grounding |

Blades | No chipping or cracking |

Back Gauge | Smooth operation, no jamming |

Emergency Stop Button | Normal function |

Safety Precautions | Protective cover intact |

Any abnormality must be rectified immediately; operation with a fault is strictly prohibited.

Electrical System:

- Ensure power supply voltage is normal and grounding is reliable.

- Emergency stop button is in the released position.

- Control cabinet has no abnormal noises or odors.

Hydraulic System:

- Hydraulic oil level is maintained above 2/3 of the gauge.

- No leaks in the pipelines.

- Pressure gauge reading is normal.

Mechanical System:

- Upper and lower blades have no cracks or obvious wear.

- Blade fastening bolts are not loose.

- Back gauge moves smoothly without jamming.

5. Power-on and System Startup Procedure

Correct Power-on Sequence:

- Turn on the main power supply

- Turn on the control cabinet power supply

- Start the CNC system

- Start the hydraulic system motor

- Run under no-load for 1–2 minutes

In winter or low-temperature environments: Preheat under no-load for 5–10 minutes.

6. Parameter Setting and Debugging (Core Steps)

1) Shearing Length Setting

- Input the back gauge dimension (mm) via the CNC system.

- Select single shearing / continuous shearing mode.

2) Shearing Gap Adjustment (Extremely Important)

Recommended shearing gap reference value:

Materials | Gap (percentage of plate thickness) |

Carbon steel | 6%–8% |

Stainless steel | 8%–10% |

Aluminum plate | 4%–6% |

- Too small a clearance: rapid blade wear, heavy load.

- Too large a clearance: large burrs, poor shearing edge.

3) Shearing Angle Adjustment (if applicable)

- Thicker plate → Slightly larger shearing angle

- Thinner plate → Slightly smaller shearing angle

This reduces instantaneous shearing force and protects the cutting tool.

7. Formal Shearing Operation Procedure

1) Loading and Positioning

- Place the sheet flat on the workbench, close to the front/side guard.

- Ensure the sheet is perpendicular to the blade.

2) Shearing Method Selection

- Single Shearing: Trial cut, accuracy confirmation

- Continuous Shearing: Batch production

3) Shearing Execution

- Remove both hands from the blade’s danger zone.

- Step on the foot switch or press the start button.

- Retrieve the sheet after shearing is complete.

It is strictly forbidden to put your hands into the blade area to retrieve the sheet.

8. Key points for shearing quality inspection

Inspection Items | Acceptable standards |

Dimensions | ±0.2–0.5 mm (depending on equipment precision) |

Sheared Surface | Smooth, without obvious burrs |

Sheet Material | No twisting, no pressure marks |

If a problem is found, immediately:

- Stop the CNC hydraulic plate shearing machine

- Check the blade gap, back gauge, and blade condition

9. Shutdown Procedure

Correct Shutdown Sequence:

- Stop shearing action

- Return back gauge to zero or safe position

- Close hydraulic system

- Disconnect CNC system

- Disconnect main power supply

10. Daily Maintenance and Care of Plate Shearing Machine

Daily Maintenance:

- Clean blades and worktable of metal shavings

- Check oil level

- Observe for abnormal sounds and vibrations

Weekly Inspection:

- Tighten bolts

- Lubricate guide rails and lead screw

- Check cables and limit switches

11. Safety Precautions (Must Remember)

- Shearing of excessively thick or wide plates

- Shearing without adjusting blade gap

- Entering the blade edge to retrieve material

- Operating with protective cover removed

- Multiple operators on one machine simultaneously

12. Common Problems and Troubleshooting

Faults | Possible reasons | Solutions |

Large burrs at the cut | Excessive clearance | Reduce tool gap |

Inaccurate dimensions | Back gauge deviation | Recalibrate |

Excessive vibration | Loose blades | Tighten blades |

Unable to cut | Low hydraulic pressure | Check oil pump/pressure |

13. Summary of Key Points for CNC Shearing Machine Operation

Inspect the CNC shearing machine equipment → Set dimensions and blade gap → Place the sheet metal tightly against the back gauge → Trial cut for confirmation → Perform formal shearing (hands away from the blade) → Stop the machine and disconnect the power.

CNC Shearing Machine Operation Steps:

- Place the sheet metal stably on the worktable.

- Ensure the sheet metal is firmly against the front or side gauge, ensuring accurate positioning.

- Ensure both hands are away from the blade and danger zones.

- Perform a trial cut to check dimensions and shearing quality.

- After confirming everything is correct, perform the formal shearing.

- Remove the sheet metal only after shearing is complete; never remove the sheet metal during the cutting process.

Key Points:

- Check before starting the machine

- Do not shear if the blade gap is not adjusted

- Keep hands away from the blade for safety

- Stop the machine immediately if there are any abnormalities.

After plate shearing, check the following:

- Whether the dimensions meet the requirements (generally ±0.2~5 mm).

- Whether the sheared surface is straight and whether the burrs are too large.

- Whether the sheet metal is twisted or has indentations.

- If a problem is found, thecnc plate shearing machine should be stopped immediately and the parameters readjusted.