Table of Contents

The key to use sheet metal deburring machine is safety, correct parameter settings, and standardized operating procedures. When operating a sheet metal deburring machine, you need to adjust the specific method according to the type of equipment (such as abrasive belt type, roller brush type, drum type, eddy current type, etc.).

The following are the general operating steps of a standard sheet metal deburring machine, which is applicable to the deburring machines used in most industrial workshops.

1. How to use the sheet metal deburring machine?

1) Preparation before starting the machine

- Check the deburring equipment

Whether the power supply and air source are connected normally.

Check whether the sanding belt, roller brush, roller, etc. are installed firmly and without damage.

Check whether the emergency stop button is reset.

- Clean the metal sheet

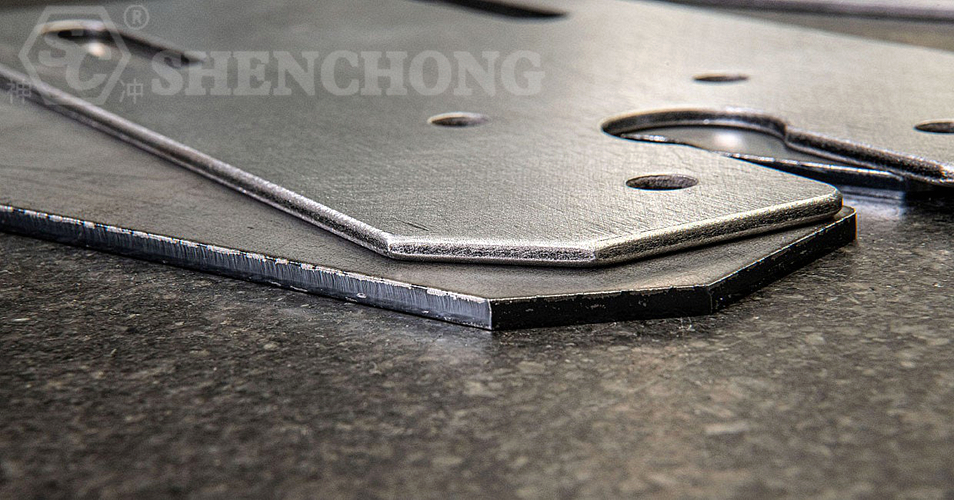

Remove oil, welding slag, and iron filings from the surface of the metal plate.

Avoid foreign objects from damaging the equipment or reducing the deburring effect.

- Setting parameters

Set according to the material of the plate (such as stainless steel, aluminum plate), thickness, and severity of burrs:

- Conveying speed

- Grinding intensity (sand belt/brush head speed and pressure)

- Processing method (single-sided/double-sided, single brush/double brush)

- Whether to turn on the vacuum system

2) Sheet metal deburring machine operation steps

- Start the equipment

Turn on the main power → Start the operating system → Turn on the sanding belt/brush head → Turn on the conveying device.

Confirm that the dust collection system is operating normally.

- Insert the workpiece

Put the metal sheet into the feed table smoothly.

Note that the sheet is flat and must not be skewed or stacked.

For double-sided equipment, ensure that the processing surface is facing correctly.

- Test run inspection

Use a sample sheet to test the machine and observe the deburring effect.

Check for residual burrs, scratches, slipping and other problems.

Adjust the pressure or speed parameters if necessary.

- Formal processing

Feed the sheet continuously and keep the feeding spacing consistent.

The operator observes the running status of the sheet in real time.

Sorting out the material in time and checking the processing effect.

3) Operation over

- Turn off the equipment

Stop conveying → turn off the brush head/sand belt → turn off the power.

Turn off auxiliary equipment such as vacuum cleaners.

- Cleaning and maintenance

Clean up residual iron filings and dust.

Check whether the sand belt and roller brush need to be replaced.

Wipe the equipment casing to keep it clean and dry.

- Record the equipment status

If there is any abnormality or failure, make a record and report it for repair.

Perform lubrication and maintenance regularly.

2. Safety precautions for metal sheet deburring machine operation

When use sheet metal deburring machine, operating safety is of vital importance. Deburring machines usually run sanding belts, brush heads or rollers at high speeds, which poses certain risks to the operator’s hands, eyes, and respiratory system, so the operating procedures must be strictly followed.

1) Safety check before operation

- Power supply and air source

Ensure that the power supply and air source of the equipment are connected reliably without damage or leakage.

Check whether the emergency stop button functions normally.

- Equipment status

Check whether the sanding belt, brush head, roller, etc. are intact and firmly installed.

Do not use damaged or severely worn consumables.

Check whether the shield is intact and the safety door is closed.

- Personal protective equipment

Protective glasses, dust masks, cut-resistant gloves, and safety shoes must be worn.

Long hair must be tied up, and scarves, necklaces, and draping clothing are strictly prohibited.

2) Precautions during operation

- Do not touch the work area with bare hands

Do not allow your hands to approach the sanding belt, brush head, or the inlet and outlet areas.

If a jam occurs, the machine should be stopped first and then processed.

- Safe feeding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Operation monitoring

The operator should be on duty throughout the process and observe the operating status.

If there are abnormalities such as abnormal noise, slipping, and smoking, stop the sheet metal deburring machine immediately and check.

- Control the intensity of use

Do not run continuously at high load for a long time to prevent the equipment from overheating or increasing loss.

3) Precautions during shutdown and maintenance

- Shutdown sequence

Turn off the grinding head, conveying, dust removal system, and power supply in the correct order.

Clean the machine debris and keep the workbench clean and tidy.

- Maintenance and repair

Before maintaining the equipment or replacing accessories, the power and gas must be completely cut off.

Maintenance work must be carried out by professionals, and the electronic control part must not be disassembled without authorization.

4) Other considerations

Item | Description |

Untrained personnel are prohibited from operating | New employees must be trained and qualified before they can operate independently |

Do not put non-metallic materials into the equipment | Wood, plastic, and oily dirt are prohibited from being handled |

Emergency treatment | Memorize the location of the emergency stop button and the power-off procedure |

Equipment is prohibited in flammable and explosive environments | Deburring machine must not be operated in an environment with flammable gas or dust |

Summary: Remember the core of safety in three sentences

- Check before going to work, wear protective gear, and press emergency stop in case of an accident.

- Don’t stretch your hands when operating, and lay the plate flat.

- Turn off the power supply when shutting down, and don’t be lazy when cleaning.

Related articles for reference: