Table of Contents

Intelligent sheet metal manufacturing is an advanced manufacturing model that applies intelligent manufacturing technology to the entire process of sheet metal processing. It integrates automation, digitization, networking and intelligent means, and aims to improve production efficiency, product quality and flexibility in responding to the market.

1. What is intelligent sheet metal manufacturing?

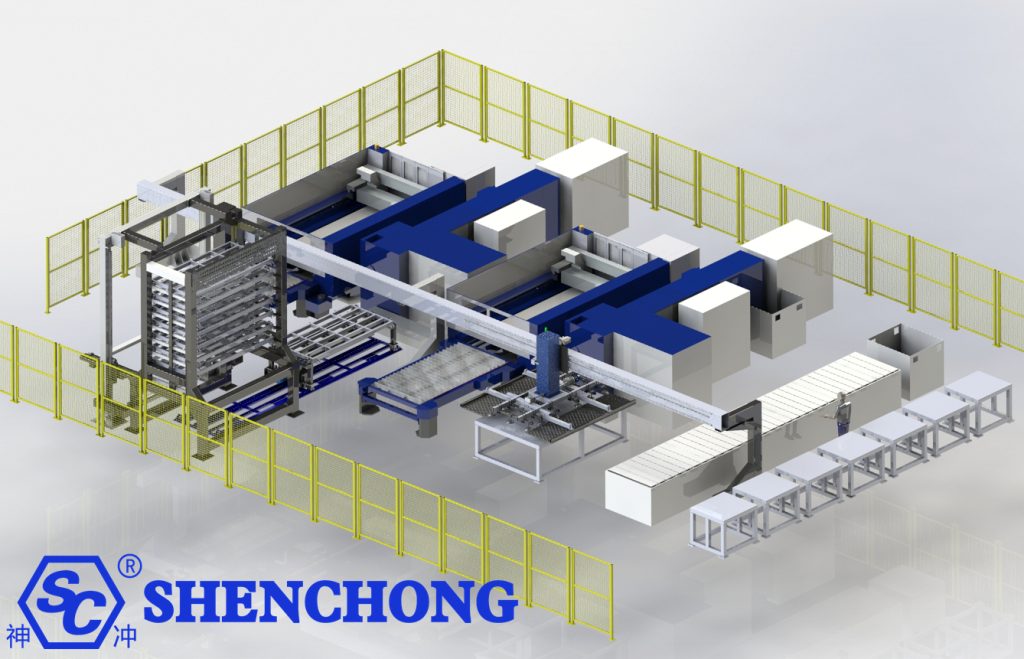

Intelligent sheet metal manufacturing uses intelligent equipment, automatic control systems, digital software platforms and data-driven technologies to optimize and integrate the entire process of sheet metal processing (design, cutting, bending, welding, spraying, assembly, warehousing, etc.), and ultimately achieves high-efficiency, low-energy consumption, flexible and intelligent production.

Intelligent sheet metal manufacturing refers to the comprehensive application of automation, digitization and intelligent technologies to all aspects of sheet metal processing, such as design, scheduling, cutting, bending, welding, grinding, testing, warehousing and logistics, to achieve a modern manufacturing model with high efficiency, high quality, flexibility and visualization.

It is the core direction of the transformation and upgrading of the sheet metal industry from traditional “manual drive + experience management” to “data drive + intelligent decision-making”.

1) Basic characteristics of intelligent sheet metal manufacturing

Comparison table of traditional sheet metal processing and intelligent sheet metal processing:

Traditional sheet metal | Intelligent sheet metal |

Manual operation, low efficiency | Automated equipment collaborative operation |

Disconnected process, chaotic flow | System control, process integration |

Management relies on experience | Data-driven intelligent management |

Unstable quality | Real-time monitoring and precise control |

Difficult to control costs | Comprehensive optimization, cost reduction and efficiency improvement |

2) The value and significance of intelligent sheet metal manufacturing

- Higher efficiency: significantly shorten the production cycle

- More stable quality: reduce human errors

- Faster response: quickly adapt to customized, multi-variety and small batch requirements

- Lower cost: reduce labor and improve material utilization

- Clearer management: achieve process transparency and real-time decision-making

- More sustainable development: support green manufacturing and energy consumption control

2. Key technical components of intelligent sheet metal manufacturing

The key technical components of smart sheet metal manufacturing are the basis for achieving its high efficiency, automation, flexibility, visualization and intelligence. The following are the core technology modules and descriptions:

1) Core technology and composition

- Intelligent CNC processing equipment

CNC laser cutting machines, CNC bending machines, CNC punching machines, etc. are equipped with intelligent control systems.

It has the functions of automatic programming, remote monitoring, and real-time feedback of processing data.

- Automatic loading and unloading and handling system

Automated feeding devices, robotic arms, AGV carts, etc. realize unattended operation.

Seamlessly connect with the production line to reduce manual intervention.

- MES system (manufacturing execution system)

Manage workshop production processes, task assignments, and progress tracking.

Provide real-time production data analysis and visualization.

- Digital management of sheet metal processes

3D modeling + CAM automatic programming + process simulation.

Support flexible manufacturing and small batch customization.

- Intelligent warehousing and logistics system

Automatic sorting, stacking, inventory management and material traceability.

- Intelligent quality inspection

Online measurement equipment, machine vision inspection, automatic defect identification.

2) List of core system architectures for intelligent sheet metal manufacturing

System module | Function description |

Intelligent design system (CAD/CAM integration) | Realize 3D modeling, automatic flattening, and intelligent process path planning. |

ERP system | Enterprise resource planning, unified scheduling of materials, manpower, finance and other resources. |

MES system | Production execution system, connecting plans and equipment, realizing process monitoring and scheduling. |

WMS system | Intelligent warehousing system, automatic warehousing and inventory management. |

Industrial Internet platform | Realize equipment networking, data collection and remote control. |

3) Key technical architecture

- Digital design and process planning

3D modeling and digital twin

CAM programming automation

Process optimization and simulation verification

- Intelligent production scheduling and dispatching system

MES system real-time dispatching

Dynamic work order management

Task visual tracking

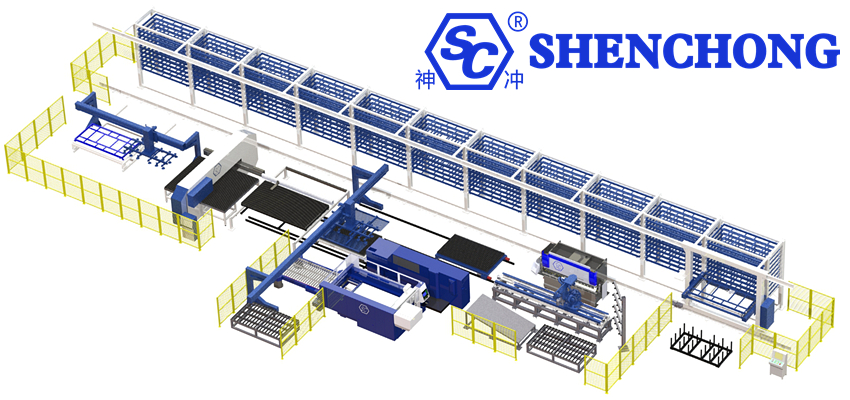

- Automated processing equipment

Automatic loading and unloading laser cutting machine

CNC servo bending machine with follow-up device

Flexible welding robot and grinding unit

- Internet of Things and data acquisition

Equipment networking (industrial Ethernet, 5G, etc.)

Real-time feedback from sensors

Data acquisition and cloud platform docking

- Intelligent warehousing and logistics

AGV trolley/robot handling

Automatic three-dimensional warehouse

Barcode/RFID material traceability

- Quality monitoring and traceability system

Online detection and AI visual recognition

Quality data analysis and traceability

- Collaborative management platform

ERP + MES + WMS + SCADA integration

Integrated manufacturing operation management

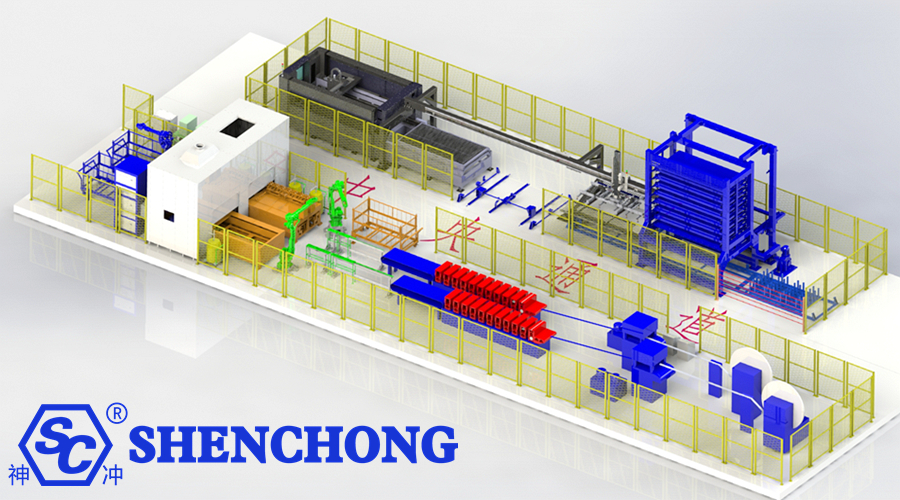

4) Key equipment and technologies for intelligent sheet metal manufacturing

- Intelligent cutting: fiber laser cutting machine, automatic nesting, edge recognition, code scanning and reading tasks.

- Intelligent bending: CNC press brake bending machine + automatic mold change system + follow-up robot arm assisted bending.

- Intelligent welding: welding robot + trajectory recognition + weld seam automatic tracking system.

- Automatic loading and unloading: robot arm, AGV logistics vehicle, stereoscopic warehouse system, etc.

- Quality inspection: laser measurement system, visual inspection system, online calibration.

3. Advantages of sheet metal intelligent manufacturing

Compared with traditional sheet metal processing mode, intelligent sheet metal manufacturing has significant efficiency advantages, quality assurance, flexible response and lean management capabilities.

The following systematically summarizes its main advantages from multiple perspectives:

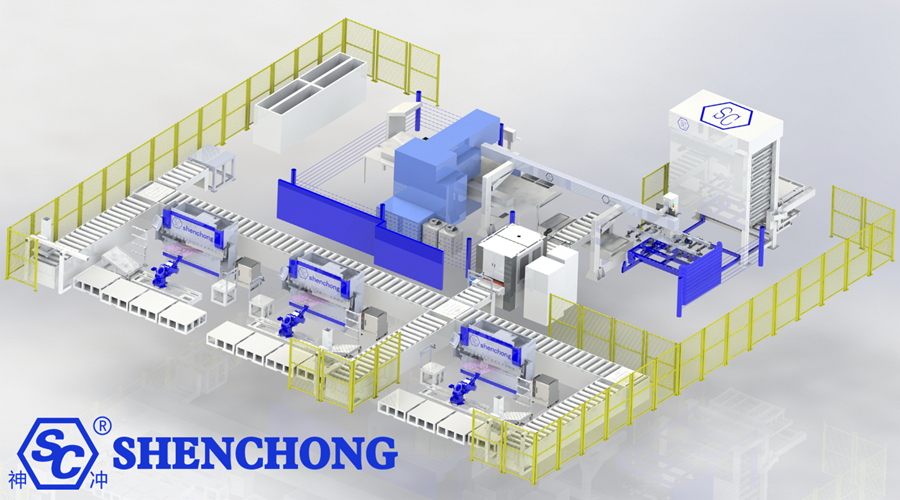

1) Significantly improved production efficiency

- Automatic loading and unloading, automatic processing, automatic handling

Greatly reduce manual participation, shorten the operation cycle, and increase unit time output.

- Open up the process to achieve seamless connection of processes

Integrate and optimize processes such as laser cutting, bending, welding, and grinding to reduce waiting and handling.

- Intelligent production scheduling and dispatching system

Dynamically optimize resource allocation to reduce the incidence of idling and bottlenecks.

2) Stable and reliable processing quality

- Servo control + digital process parameter management

High processing accuracy and strong consistency to avoid human errors.

- Visual inspection and real-time monitoring

Defect identification, error feedback, online compensation, and closed-loop quality control.

- Historical data tracing and quality analysis

Quickly locate the source of the problem and support continuous optimization.

3) Strong flexible and personalized manufacturing capabilities

- Support multi-variety, small batch mixed production

Switching process is fast and flexible to meet customer personalized customization needs.

- Flexible production line is reconfigurable and scalable

Support modular replacement of equipment or process flow to adapt to product structure adjustment.

4) Significant reduction in labor costs

- Replace repetitive labor with machines

Save labor for operators, porters, inspectors and other positions.

- System centralized management, simplified operation difficulty

Reducing the skill threshold of personnel and supporting “less-man, unmanned” production.

5) Data-driven decision-making is more scientific

- Full process data can be collected, analyzed and traced

Provide a basis for production optimization, quality improvement, and energy consumption control.

- Assist management decision-making

Order evaluation, capacity forecasting, equipment maintenance plan, etc. based on real-time data.

6) Reduced operating costs and resource waste

- Intelligent typesetting and material optimization

Laser cutting system automatically arranges samples to improve material utilization.

- Maximize equipment efficiency

Reduce idling, reduce downtime due to failures, and improve OEE (overall equipment efficiency).

- Energy consumption monitoring and energy-saving control

Save energy, water, gas and other resource expenses, and support green manufacturing.

7) Management transparency and collaborative improvement

- Visual monitoring platform

Managers can grasp orders, progress, equipment status and other information in real time.

- ERP, MES, WMS integrated collaboration

Realize information connection throughout the entire process of procurement, warehousing, production and delivery.

8) Assist enterprises in transformation and upgrading and market competition

- Enhance customer response capabilities and delivery guarantee

Intelligent manufacturing improves response speed and service capabilities and wins customer trust.

- Improve brand image and technical threshold

Intelligent factories represent the advanced level of the industry and are conducive to market expansion and bidding.

- Meet the “dual carbon” goals and green certification requirements

Intelligent energy-saving systems help achieve low-carbon emission goals.

4. Importance of transformation to intelligent manufacturing

The transformation from traditional sheet metal manufacturing to intelligent sheet metal manufacturing is a strategic choice for the current manufacturing industry to cope with market competition, cost pressure, technological change and sustainable development needs.

The following details its importance from multiple dimensions:

1) Urgent need to adapt to market changes

- Changes in customer needs: diversification, personalization, and fast delivery in small batches

The traditional sheet metal model is OK for single products, but it is prone to problems such as low efficiency, slow switching, and many errors and omissions when facing personalized orders.

Smart manufacturing has flexible production and rapid response capabilities, and can effectively deal with high-frequency changes and fragmented orders.

- The pressure to shorten delivery time continues to increase

Smart scheduling and automated operations can significantly shorten the delivery cycle, enhance customer satisfaction and repurchase rate.

2) Solve the dilemma of cost and employment

- Rising labor costs

The sheet metal industry has a large demand for labor, but skilled workers are difficult to recruit, costly, and highly mobile.

Automation and robot replacement of labor are the key to stabilizing production capacity and controlling labor costs.

- Raw material cost fluctuations

Smart typesetting and smart warehouse management improve material utilization and reduce waste.

- Low equipment utilization and extensive management

Traditional equipment has serious information islands and cannot monitor status in real time.

Through intelligent device interconnection and predictive maintenance, improve equipment OEE (overall efficiency) and extend service life.

3) Strategic path to enhance core competitiveness

- Intelligent manufacturing improves overall operational efficiency

Automation + informationization + intelligence connects all links to achieve cost reduction and efficiency improvement.

- Digital management supports lean production

The entire process of orders, materials, equipment, and quality is transparent, which facilitates planning and decision-making.

Support enterprises to transform from “experience-driven” to “data-driven”.

- Establish a corporate technology image and enhance market voice

In the industrial chain cooperation, it has stronger delivery capabilities, quality assurance and cost control capabilities, and enhances its attractiveness to high-end customers.

4) Respond to policies and industrial trends

- In line with the strategy of manufacturing power

The world vigorously promotes intelligent manufacturing, industrial Internet, and green manufacturing.

- Environmental protection and low-carbon production requirements

The traditional model has high energy consumption and heavy pollution, and it is difficult to pass the energy conservation and environmental protection assessment.

Intelligent manufacturing realizes energy consumption monitoring and fine emission management, helping to achieve the “dual carbon” goal.

5) Prevent the risks of "being replaced" and "being eliminated"

Leading companies in the industry have completed intelligent transformation. If traditional companies do not follow up, they are likely to be left behind or even eliminated.

Workshops with outdated equipment, intensive labor and low efficiency cannot accept high-end orders and find it difficult to obtain policy or capital support.

6) Achieve the leap from "manufacturing" to "intelligent manufacturing"

It is not just equipment upgrade, but also a comprehensive transformation of system, process, organization and culture.

Achieve a leap from low value-added and extensive growth to high value-added and sustainable development.

7. Summary

Intelligent sheet metal manufacturing is the result of the upgrade of traditional sheet metal processing to digitalization, automation and intelligence, and is the concrete embodiment of intelligent manufacturing in the sheet metal industry. It not only improves efficiency and quality, but also promotes the development of flexible production and customized services.

Advantages of intelligent sheet metal manufacturing

- Efficiency improvement: process integration, reduced manual intervention, and less or even unmanned production.

- Flexible production: quick response to personalized, multi-variety small batch orders.

- Reduce costs: save labor, reduce scrap rate, and improve material utilization.

- Data-driven: support accurate decision-making and continuous optimization.

- Visualization and transparency: management can control production dynamics in real time.

Development trend

- Transformation to green manufacturing and low-carbon energy saving

- Strengthen the application of AI and edge computing in quality prediction and equipment maintenance

- Realize multi-station collaboration and full-process closed loop

- Build an industrial Internet platform for the sheet metal industry

The transformation of traditional sheet metal manufacturing to intelligent manufacturing is not an option, but a must for survival. It not only solves the current cost, efficiency, and delivery problems, but also determines the competitiveness and vitality of the company in the next 5 or even 10 years.