Table of Contents

It is a practical FAQ (Frequently Asked Questions) on intelligent sheet metal processing for manufacturing managers, engineers, and procurement personnel. It covers core issues from concepts and equipment to system integration and maintenance, and encompasses key questions and practical advice regarding intelligent sheet metal processing (cutting, stamping/punching, bending, welding, surface treatment, automated loading and unloading, digital shop floor management, and more).

1. Basic Concepts Of Intelligent Sheet Metal Processing

Q1: What is intelligent sheet metal processing?

A: Intelligent sheet metal processing refers to a manufacturing method that utilizes CNC technology, automated equipment, and information systems to achieve efficient, precise, automated, and digitalized sheet metal processing (cutting, bending, welding, assembly, warehousing, etc.). The core goals are to improve production efficiency, reduce labor costs, and ensure consistent quality.

Q2: What is the difference between intelligent sheet metal processing and traditional sheet metal processing?

A: Traditional processing relies on manual labor, resulting in low efficiency and large errors. Intelligent processing utilizes automated equipment (such as laser cutting machines, automatic bending centers, robotic welding cells, and intelligent warehousing systems) linked to an MES system to achieve unmanned production and data-driven management.

Q3: What is the core value of intelligent sheet metal processing?

A: Improved production capacity and consistency, shortened delivery times, reduced defect rates and labor costs, real-time visualization of production, rapid response to small batch and high-variety demands, and improved equipment utilization.

Q4: What are the core equipment for intelligent sheet metal manufacturing?

A:

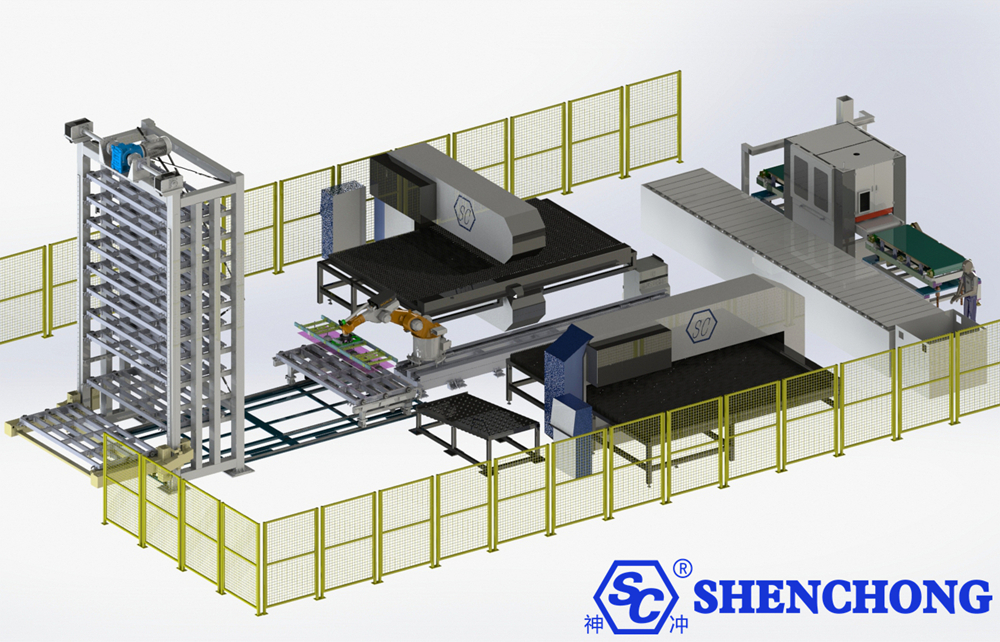

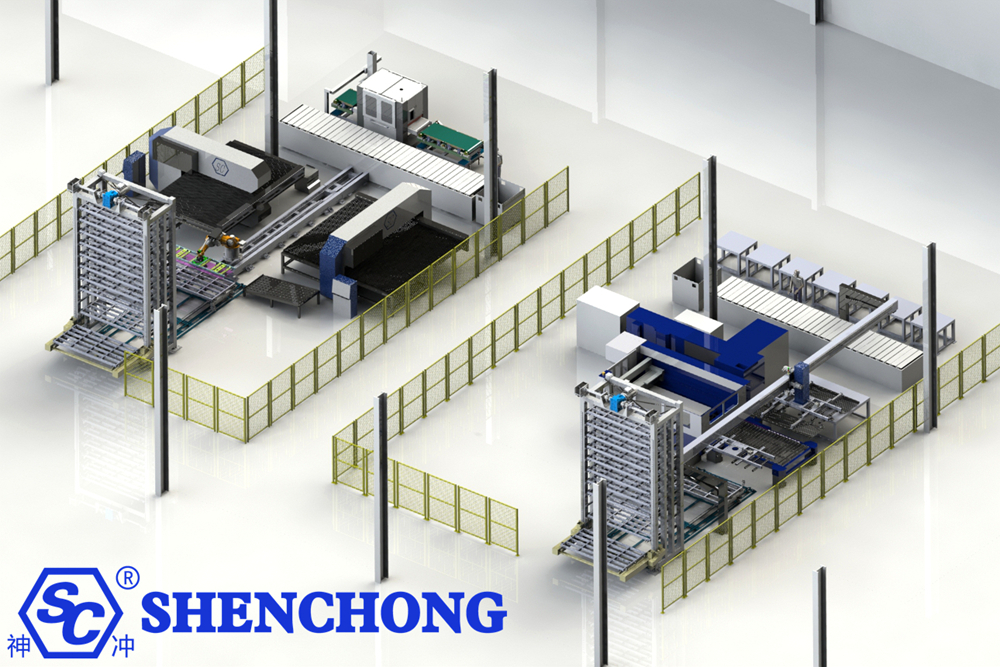

- Fiber laser cutting machine

- CNC press brake / automated bending center

- Robotic bending unit

- Intelligent sheet metal storage / automated loading and unloading system

- Automated welding robot

- Production management system (MES/ERP)

2. Equipment And Systems

Q5: What equipment is essential for a smart sheet metal workshop?

A: Fiber/CO₂ laser cutting machines, CNC press brakes (including backgauge side shift/robotic units), automatic shearing machines with automatic feeding, loading/unloading/clamping robots, robotic welding/assembly units, and online inspection equipment (thickness measurement, shape measurement, and visual inspection).

Q6: What is an intelligent bending center?

A: An intelligent bending center is a fully automated sheet metal bending machine that uses robotic arms to automatically grasp, position, rotate, and bend, achieving a single-step forming process for complex workpieces and reducing manual intervention.

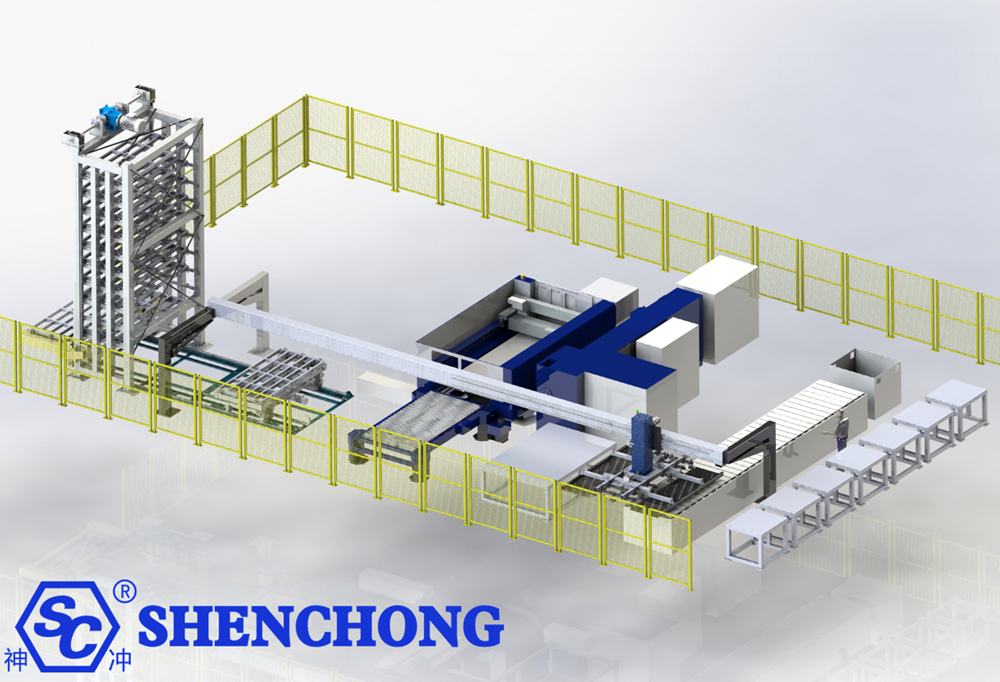

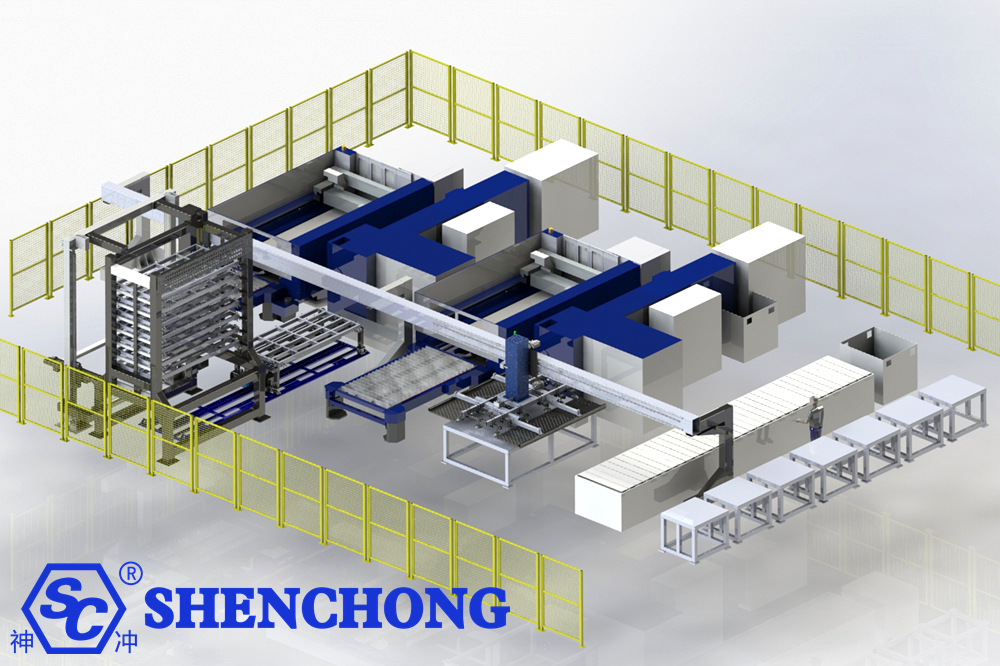

Q7: What is the function of an intelligent sheet metal storage system?

A: Automated high-bay warehouses enable automated storage, sorting, and loading and unloading of sheet metal, improving space utilization, reducing handling time, and automating the entire “raw material – production – finished product” process.

Q8: What are the advantages of robotic bending units over manual bending?

A:

- High precision and good consistency

- Can operate 24/7

- Suitable for batch and multi-product production

- Reduced risk of work-related injuries and labor costs

3. Integration and Application

Q9: How does an intelligent sheet metal processing system achieve device interconnection?

A: Connecting to the MES system through industrial communication protocols (such as OPC UA and Ethernet/IP) enables data collection, production scheduling, and equipment status monitoring.

Q10: Which industries are suitable for intelligent sheet metal processing?

A: Electrical cabinets, sheet metal enclosures, architectural decoration, automotive parts, kitchen equipment, air conditioning and ventilation, agricultural machinery, and rail transit.

Q11: What is the typical return on investment (ROI) for an intelligent sheet metal production line?

A: Depending on the degree of automation, production scale, and labor costs, the ROI period is generally 1.5 to 3 years. Companies with large production volumes and standardized products experience faster returns.

4. Digitalization and Software

Q12: What do MES, ERP, and CAM do respectively?

A: ERP manages business and materials, MES controls shop floor execution and tracking, and CAM (and CAD/CAM) handles part development, layout, and NC code generation. The integration of these three enables closed-loop control from order to delivery.

Q13: Is automatic nesting important?

A: It is very important. Efficient nesting can significantly reduce material waste, shorten cutting time, and increase output. Supporting mixed nesting of multiple materials and multiple work orders is particularly suitable for small batches and diverse scenarios.

Q14: How can real-time equipment monitoring and remote diagnostics be achieved?

A: Connect PLCs and devices using industrial communication protocols such as OPC-UA and MTConnect, upload data to the cloud, or deploy a local data platform. Combined with dashboards and alarm systems, this enables real-time OEE monitoring and predictive maintenance.

5. Process and Quality

Q15: How do you ensure punching/cutting integrity and burr control?

A: Select appropriate tools/process parameters, maintain tool sharpness, implement online chip cleaning and vacuuming, use visual or burr inspection for critical steps, and design chamfering or deburring processes when necessary.

Q16: How do you control bending accuracy fluctuations?

A: Precise backgauge control, automatic torque/angle compensation, workpiece positioning fixtures, programmed bending compensation curves, and an online measurement feedback loop.

Q17: How do you achieve finished product traceability?

A: Record production process parameters, equipment ID, operator, test results, and inspection images for each batch/piece in the MES and barcode/RFID systems to establish a complete traceability chain.

6. Operation And Maintenance

Q18: Is intelligent processing equipment maintenance complex?

A: Intelligent equipment maintenance primarily involves daily cleaning, lubrication, software updates, and sensor testing. Systems typically include self-diagnostic and alarm functions, making maintenance more scientific and simple.

Q19: If a device malfunctions, how can the problem be quickly located?

A: The system uses remote diagnosis, real-time alarm logging, and cloud-based data analysis to help engineers quickly identify the problem and propose a solution.

Q20: Is professional operation required?

A: Initial technical training is required. Once proficiency is achieved, an average operator can operate the equipment through the human-machine interface. Systems typically feature a graphical interface and automatic programming.

7. Safety And Compliance

Q21: What are the safety considerations for intelligent equipment?

A: Mechanical guarding, photoelectric/light barrier interlocks, robot safety fencing/collaborative mode, emergency stop, cutting fume and laser protection, operator PPE, and work permit systems.

Q22: Are there any standards that need to be followed?

A: The equipment should comply with the electromechanical safety standards of the country/region where it is located (such as CE, ISO 12100, etc.). Laser equipment must be protected according to laser safety standards. Software and data must consider cybersecurity and backup strategies.

8. Investment and Cost-Effectiveness

Q23: What is the typical payback period for intelligent equipment investment?

A: It strongly depends on the product mix and production volume—high-mix small batches: 1–3 years. traditional large batches: 6–18 months. An ROI simulation is recommended (taking into account material savings, reduced labor costs, increased production capacity, reduced defect rates, and reduced delivery times).

Q24: How should suppliers/manufacturers be evaluated?

A: Consider equipment performance and stability, software openness/API integration capabilities, after-sales response, on-site commissioning and training, proven implementation cases, and localized service capabilities.

Q25: Gradual transformation or all-in-one investment?

A: If budget and production capacity allow, building a digital workshop all at once is more consistent. However, most companies adopt a “step-by-step, iterative” approach—first automating key processes, then integrating MES/ERP and scheduling optimization.

9. Future Trends

Q26: What are the development trends of intelligent sheet metal processing?

A:

- Fully unmanned production lines

- Integration of AI and visual inspection

- Cloud manufacturing and remote monitoring

- Flexible production and quick line changeovers

- Green energy conservation and carbon emission control

Q27: How can companies gradually upgrade to an intelligent sheet metal factory?

A:

- Start with single-machine automation (such as automatic loading and unloading for laser cutting).

- Move to process automation (bending and welding cells).

- Finally, achieve system integration (intelligent warehousing + MES system + intelligent scheduling).

10. Summary

– What is intelligent sheet metal processing?

Efficient sheet metal cutting, bending, welding, and assembly are achieved through automated equipment, robots, and CNC systems.

– What are the advantages of intelligent processing?

Improves precision and efficiency, reduces labor costs, and enables flexible production and digital management.

– What are the main equipment?

Fiber laser cutting machines, CNC press brakes, automatic feeding systems, robotic bending units, sheet metal storage, etc.

– What industries are suitable for?

It is widely used in electrical cabinets, automotive parts, architectural metals, home appliances, and machinery manufacturing.

– How to achieve automated production?

Connecting equipment through an MES system enables automated control of the entire process from design and scheduling to processing.

– What is the return on investment for intelligent processing systems?

Typically, it is 1 to 3 years, depending on the production scale and degree of automation.

– Is ongoing maintenance complex?

Maintenance primarily consists of software upgrades and routine equipment maintenance, and is simple to operate.

– How to choose the right intelligent sheet metal processing solution?

A comprehensive evaluation based on production volume, material type, process flow, and budget.

![Intelligent Sheet Metal Processing [FAQ]](https://www.shen-chong.com/wp-content/uploads/2025/11/Intelligent-Sheet-Metal-Processing-FAQ-1024x512.jpg)