Table of Contents

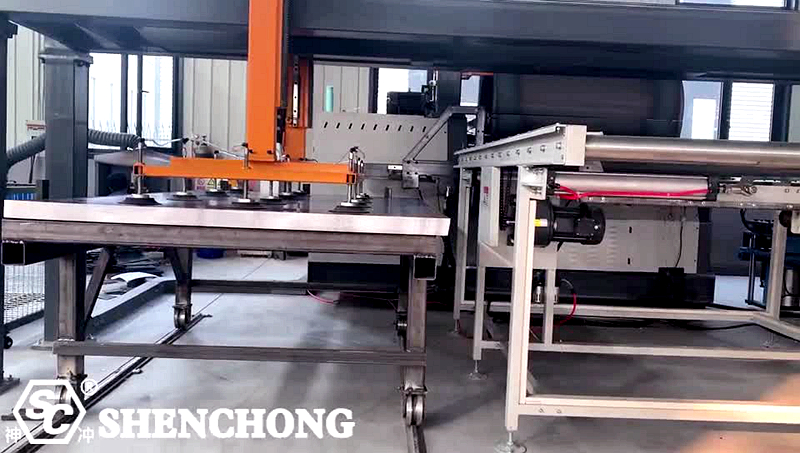

Automated sheet metal rolling systems integrate sheet metal rolling machines (typically three-roll or four-roll machines) with automatic loading, unloading, handling, positioning, detection, and scheduling control systems. The metal rolling automation enables unmanned or minimally manned operation from flat plate loading → automatic centering → rolling → automatic unloading → measurement and repetitive production.

Suitable for: mass production and stable manufacturing of round/conical parts such as cylinders, pipes, storage tanks, ventilation ducts, pressure vessel shells, and vehicle frame components.

1. Components Of Metal Rolling Automation Unit

1) Automatic Loading and Unloading System

The automatic loading and unloading system for plate rolling machines is an intelligent auxiliary device developed to solve problems such as difficult plate loading, insufficient centering accuracy, high manual labor intensity, and inconvenient unloading after rolling.

The system achieves full automation of the entire process before and after the plate rolling machine through “handling + centering + buffering + unloading after rolling,” significantly improving rolling efficiency and safety.

- Truss Robot (Common Solution)

- X/Y/Z three-axis servo control, suitable for handling large-size sheet metal.

- Load range: 300kg, 500kg, 800kg, 1.2 tons optional.

- Operating speed up to 80~120 m/min (light load).

- Built-in vacuum or magnetic suction system.

- Sheet Metal Loading Platform

- Can stack entire packages of sheet metal.

- Electric lifting maintains stable top layer height.

- Equipped with automatic sheet splitting device.

- Sheet Metal Positioning and Centering Mechanism

- Automatic edge alignment device.

- Automatic correction of roll direction.

- Provides positioning accuracy of ±0.5 mm (depending on sheet metal size).

- Material Clamping Fixtures

- Vacuum suction cup: suitable for carbon steel, stainless steel, and aluminum plates.

- Electro-permanent magnet clamp: high load capacity, suitable for thick plates (8~25mm).

- Mechanical jaw clamp: for heavy-duty and irregularly shaped plates.

- Automatic interface for plate rolling machine

- Interconnects with plate rolling machine control system

- Automatically identifies the starting position of the rolled plate

- Automatically plans the feeding/unloading path

- Safety interlock: Automatically locks loading and unloading when the plate rolling machine is rotating

- Post-rolling unloading platform

- Automatic receiving device for finished rolls

- Optional flipping, stacking, and roller conveyor output

- Optional finished product stacking or conveyor line connection

2) Plate Rolling Machine Main Body (Core Equipment)

Compatible Plate Rolling Machine Types:

- W11 Three-Roll Symmetrical Plate Rolling Machine

- W12 Four-Roll Plate Rolling Machine (Best for Integrated Automation)

- Upward Adjustment Type / Downward Adjustment Type / Hydraulic Drive Type

- Supports Taper Pre-Bending, Rolling, and Precision Control

3) Metal Rolling Automation Interface

- Extended Bus Protocols (e.g., EtherCAT/CANopen/Profinet)

- Open NC Program Library

- One-Click Linkage with Robots/PLCs

4) Workflow (Typical Automated Rolling Process)

- Automatic Feeding: Robot/gantry retrieves plate material from the material warehouse

- Centering and Positioning: Automatic adjustment via vision or centering mechanism

- Automatic Pre-Bending: Plate rolling machine pre-bends according to a set curve

- Automatic Rolling and Forming: Executes the rolling program

- Automatic Unloading of Finished Products: Robotic arm/cart receives material

- Roundness Detection (Optional): Automatic laser roundness measurement

- Automatic Stacking/WarehousingStorage System

2. Main Functions

- Automatic Feeding

Gantry Robot / Industrial Robot:

Achieves sheet material gripping, handling, flipping, and precise placement.

Vacuum Suction Cup Gripping Mechanism:

Adapts to different materials and sheet thicknesses (0.8–20mm), providing stable suction without scratching surfaces.

Feeding Buffer Rack:

Can pre-stack 5–20 sheets, reducing manual handling frequency.

Centering and Positioning Platform:

Automatically detects the left-right and front-back positions of the sheet material, corrects for offsets, and ensures accurate entry into the rolling mill.

- Automatic Centering and Feeding

Adaptive Edge Alignment:

Ensures accurate feeding angle through laser ranging

Automatically feeds the sheet material to the lower roller position of the rolling mill.

- Coordinated Rolling Process

Automatic Feeding Roller Conveyor / Powered Rollers:

Smoothly propels the sheet material to the rolling mill inlet.

Laser Ranging / Edge Sensor:

Automatically identifies the sheet material edge and rolling start point, improving the accuracy of the first roll.

Pneumatic / Servo Clamping Device:

Stablely clamps the sheet material, reducing slippage.

- Automatic Unloading

Carrying Trolley / Roller Support System:

Catches the rolled cylinder, preventing it from falling and deforming.

Side-Out Unloading Structure:

Automatically pushes the cylinder out of the rolling area, improving safety.

Telescopic Ejector Mechanism (for four-roll mills):

Ejects the formed cylinder from between the rolling rollers and transfers it to the unloading roller track.

3. Applicable Plate Rolling Machine Range

Comparison Table:

Plate Rolling Machine Types | Applicability | Notes |

Three-roll plate rolling machine (W11) | ★★★★☆ | Common applications, moderate load |

Four-roll plate rolling machine (W12) | ★★★★★ | Best suited for automation, stable loading position |

Large heavy-duty plate rolling machine (20~60mm thick plate) | ★★★★☆ | Requires electro-permanent magnet clamps or mechanical grippers |

Small rolling machine | ★★★☆☆ | Suitable with a light-duty robotic arm |

4. Metal Rolling Automation System Advantages

1) Significantly Reduced Labor Costs

- The number of people required per plate rolling machine is reduced from 2-3 to 0.5 (monitoring).

- No manual lifting, centering, or support during the rolling process is required.

2) Significantly Increased Efficiency

- Feeding speed increased by 50%-200%.

- Automatic positioning is more stable than manual operation.

- Suitable for batch continuous rolling operations.

3) Improved Rolling Consistency

- Automatic centering and positioning reduce offset errors.

- The straightness of the plate is more stable, and the rolling ellipticity is lower.

- Consistency across multiple batches is improved by 20-40%.

4) Enhanced Safety

- Avoids manual contact with heavy plates and the rolling area.

- Full-process laser scanning + safety interlock.

- Automatic alarm for plate offset detection.

5) Established Standardized Quality

- High consistency in feed angle.

- Rolling accuracy improved by 20-30%.

- Rolling error stabilized within ±1-2 mm.

- Suitable for continuous production in high-end pressure vessels and pipeline industries.

6) Designed Specifically for Large Sizes and Heavy Plates

- Particularly suitable for 6-40mm thick plates and large-format plates.

- Robots/trusses, in conjunction with material handling devices, can easily handle heavy materials.

5. Typical Configuration Example (Compatible with W12-12×2500)

- SC Rolling Machine Model: W12-12×2500 (12mm×2500mm)

- Loading Truss Load Capacity: 500kg

- Suction Method: Electro-permanent magnet suction + sheet separator

- Centering Mechanism: Double-sided automatic alignment + laser measurement

- Unloading Method: Automatic conveyor roller after rolling

- Total Footprint: Approximately 10m × 5m

- The layout can be customized according to your actual plate thickness, width, rolling diameter, and workshop space.

6. Summary

SC sheet metal rolling automation system consists of a plate rolling machine, automatic loading and unloading device, intelligent control software, and detection modules. It can automate the entire process of sheet metal handling from material picking, centering, pre-bending, rolling to unloading. The system uses robots or truss handling methods and is linked with the plate rolling machine for control. It has high-precision rolling, stable output, and unmanned continuous operation capabilities, making it particularly suitable for batch production scenarios such as cylindrical parts, air ducts, pipes, and pressure vessel shells.

- Increased Production Capacity: Standardized cycle time is stable and controllable, improving efficiency by 1.5–3 times.

- Reduced Manpower: The workforce is reduced from 3–4 people to 1, lowering labor intensity and costs.

- More Consistent Quality: Higher consistency in roundness and straightness, reducing rework.

- Scalable Smart Factory: Can interface with material warehouses, welding lines, and MES systems to achieve data-driven operations.