Table of Contents

Metal shearing machine blade material directly affects its cutting performance, wear resistance, service life, and processing results. Different applications require different blade performance, so the appropriate material must be selected. Below is a detailed analysis of the commonly used materials for metal shear blades.

1. Common Metal Shearing Machine Blade Material Types

Common shearing blade materials include carbon tool steel, alloy tool steel, high-carbon high-chromium steel, hot work die steel, and powder metallurgy steel. Below is a detailed classification and characteristics of common types.

1) Overview of commonly used shearing machine blade material types

Blade Material | Types | Features | Main Cutting Materials |

T8, T10 | Carbon Tool Steel | Low cost, high hardness, poor toughness | Ordinary carbon steel, copper, aluminum, and other soft materials |

9CrSi | Alloy Tool Steel | High hardness and wear resistance, high cost-effectiveness | Ordinary medium and low carbon steel |

6CrW2Si | Alloy Tool Steel | Contains tungsten, good red hardness and wear resistance | Medium-strength steel, lightweight stainless steel |

Cr12MoV | High Carbon High Chromium Steel | Excellent wear resistance and hardenability | Stainless steel, silicon steel, high-strength steel |

H13 (4Cr5MoSiV1) | Hot Work Die Steel | Excellent high-temperature strength and thermal fatigue resistance | Hot-sheared hot-rolled plate, iron plate |

SKD11/D2 | High Carbon High Chromium Steel | High strength, high wear resistance, and chipping resistance | Stainless steel, high-strength steel, silicon steel |

Powder Metallurgy Steel (e.g., ASP23) | High-End Alloy Tool Steel | Ultra-high hardness and extremely long life | High-end composite plate, wear-resistant steel |

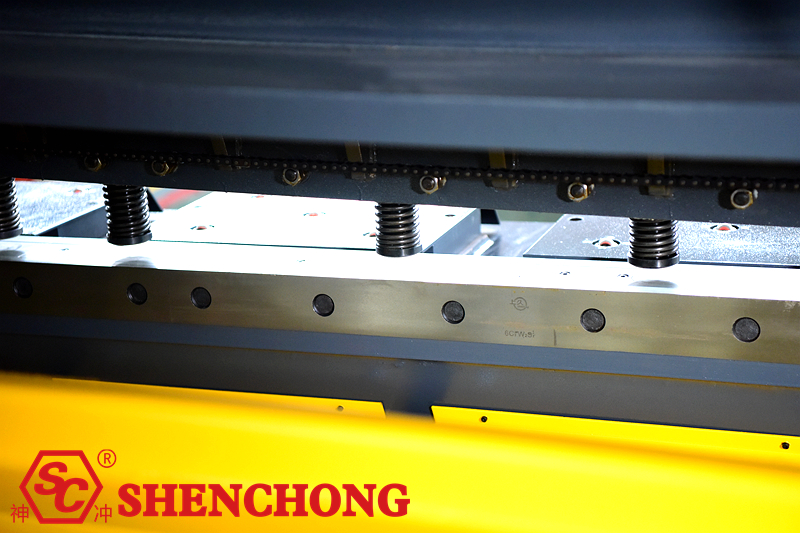

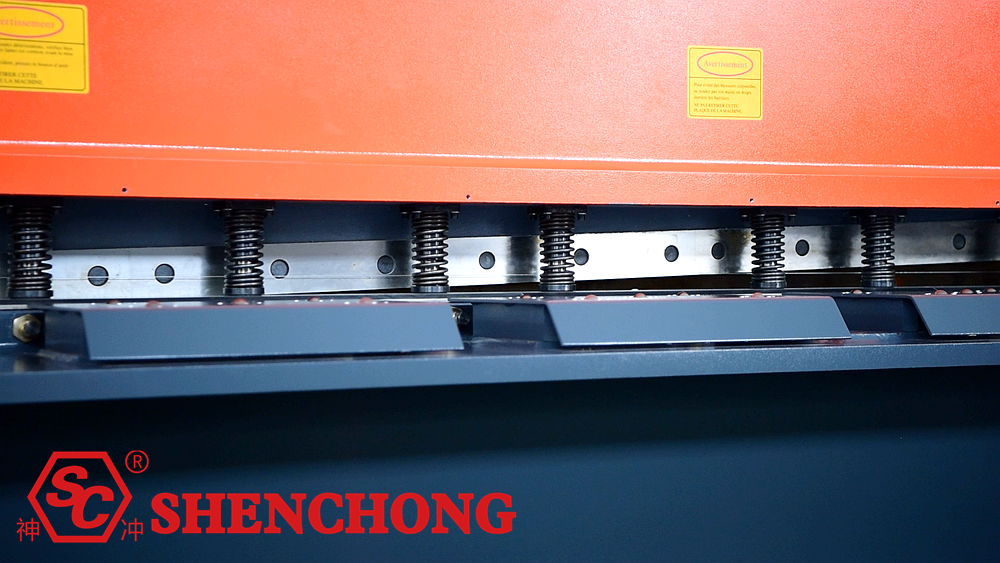

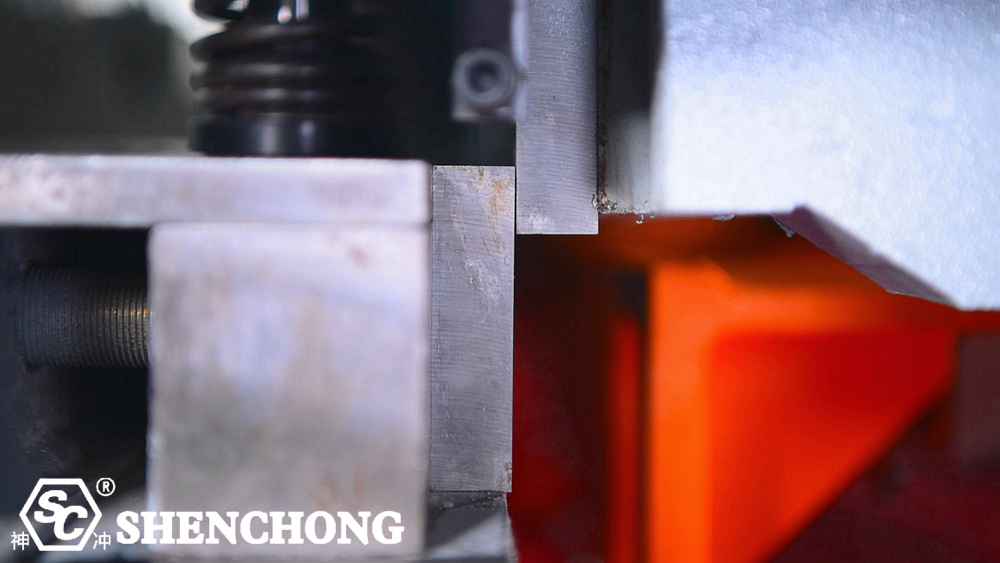

SC hydraulic guillotine shears are typically made of materials such as 9CrSi, 6CrW2Si, Cr12MoV, and H13K. The blades have a rectangular cross-section and a hardness between HRC50 and 62. They offer a high-precision, burr-free surface.

2) Detailed Characteristics of Various Blade Materials

– T8 and T10 Carbon Tool Steel

Features:

- High hardness (reaches HRC 58-62 after heat treatment)

- Low cost and good machinability

Disadvantages:

- Fair wear resistance, poor toughness

- Prone to cracking, not suitable for high-speed shearing or shearing hard materials such as stainless steel

Applications:

- Shearing of soft materials such as ordinary carbon steel, aluminum, and copper

– 9CrSi Alloy Tool Steel

Features:

- High hardness, good wear resistance

- Medium toughness

- High cost-effectiveness

Applications:

- Q235, Q345 ordinary medium and low carbon steels, stainless steel, etc.

- Representative hardness: HRC 58-60

– 6CrW2Si Alloy Tool Steel

Features:

- Contains tungsten and silicon, good red hardness

- High strength and hardness, excellent shearing performance

- Tougher than 9CrSi

Suitable Applications:

- Continuous shearing, hot shearing, and light stainless steel shearing

- Representative hardness: HRC 60-62

– Cr12MoV high-carbon, high-chromium alloy tool steel

Features:

- Excellent wear resistance and hardenability

- Moderate toughness, minimal heat treatment deformation

- Long service life

Applications:

- High-strength steel, stainless steel, silicon steel sheets, and other high-hardness materials

- Large hydraulic shearing machine blades, CNC shearing machine blades

- Representative hardness: HRC 58-60

– H13 (4Cr5MoSiV1) hot work die steel

Features:

- Excellent high-temperature strength, toughness, and thermal fatigue resistance

- Can be used in hot shearing equipment

Applications:

- Hot shearing of sheet metal, such as hot-rolled strip and hot-sheared iron plates

- Representative hardness: HRC 50-55 (after heat treatment)

– SKD11 (Japanese JIS standard)/ D2 (American Standard)

Features:

- High-carbon, high-chromium alloy steel, excellent wear resistance and hardenability

- Strong deformation resistance, long service life

Applications:

- Shearing high-strength steel, stainless steel, titanium alloys, and composite materials

- Representative hardness: HRC 58-62

– Powder metallurgy steel (such as ASP23, ASP60)

Features:

- Ultra-high hardness, excellent wear resistance, and chipping resistance

- High-end blade material

Applications:

- High-end precision shearing operations, applications requiring high wear resistance

- Representative hardness: HRC 62-65+

2. The Importance of Metal Shearing Blade Material

The quality of a metal shearing machine blade material is a key factor in determining shearing quality, efficiency, cost, and equipment life. As the shear’s direct “executing component”, the blade’s material properties directly impact the overall performance of the entire machine. The following is an in-depth analysis of the importance of blade material:

1) Key Determinants of Shear Quality

- Good material → Sharp, wear-resistant blade edge → Smooth, burr-free cut surfaces.

- Poor material → Blade edge easily blunts or cracks → Sheet edge tearing and deformation, resulting in a high scrap rate for finished products.

Application Example:

- When shearing high-strength materials such as stainless steel and silicon steel, the wrong blade material can easily lead to serious defects such as “bite” and “tear.”

2) Impacts on Blade Life and Blade Change Frequency

- High-quality materials (such as Cr12MoV and SKD11) have a blade life 2–5 times longer than ordinary materials (such as T10 and 9CrSi), or even longer.

- The material determines the blade’s wear resistance, red hardness (maintaining hardness at high temperatures), and resistance to chipping.

- High-quality blades reduce the frequency of blade changes, reducing labor, downtime, and commissioning costs.

Conclusion:

- The better the blade material, the more adaptable it is to long-term, continuous, high-intensity shearing.

3) Ensure equipment safety and stable operation

Poor-quality blades may:

- Suddenly chip or break during the shearing process, causing impact and damage to the blade holder and transmission mechanism.

- Inhomogeneous material or inadequate heat treatment can lead to stress concentration and fatigue failure.

- This can cause fluctuations in shear resistance, equipment vibration, and even hydraulic system overload.

High-quality blade material offers:

- Higher toughness and a more uniform structural distribution.

- This prevents stress concentration during shearing shock, effectively protecting the entire system.

4) Directly Affects Production Costs and Profits

Poor-quality blades, while inexpensive, can easily lead to:

- Frequent replacement

- Material waste (poor shearing)

- Finished product repair and rework

- Excessive equipment wear and increased maintenance costs

High-quality blade materials, while slightly more expensive initially, offer:

- Higher shearing efficiency

- Lower unit costs

- Longer trouble-free periods

Economic Benefit Comparison:

- One high-quality blade = the lifespan of three standard blades + Less downtime + Higher yield

5) Impacts Production Safety

- Poor-quality blades, characterized by uneven material and insufficient strength, can cause cracking or flying fragments during high-stress shearing, potentially injuring the operator.

- Substandard blades, especially when shearing high-strength steel or thick plate, pose a significant safety hazard.

High-quality blades possess:

- A rational alloy ratio

- Proper heat treatment

- A good balance of toughness, strength, and hardness, resulting in greater safety and reliability.

Summary: The Importance of Blade Material

- Cutting Quality: Smoothness, Precision, Burr Control

- Service Life: Blade Change Cycles, Cost Control

- Equipment Protection: Impact Resistance, Failure Reduction, and Longer Service Life

- Cost Control: Reduce Rework and Maintenance Downtime

- Production Safety: Prevent Splash and Operational Risks

Recommendations:

- Cutting Ordinary Carbon Steel → Choose Cost-Effective Materials Such as T10 and 9CrSi.

- Cutting Stainless Steel or High-Strength Steel → High-Performance Alloy Steels Such as Cr12MoV and SKD11 Must Be Selected.

- For High-Frequency Production or Precision Cutting → Powder Metallurgy Steels (such as ASP23) Are Preferred.

- The selected material must be combined with a specialized heat treatment process to achieve its true performance.

3. How to Choose Shear Blade Material?

The metal shearing machine blade material selection is crucial for ensuring shearing efficiency, shear quality, and blade life. Different plate materials, thicknesses, shearing frequencies, and operating conditions require different blade performance. Below are detailed recommendations for selecting shear blade material.

1) Select the blade material according to the cutting material

Shearing Material Types | Recommended blade materials | Reasons |

Ordinary carbon steel (Q235, Q195, etc.) | T10, 9CrSi | Low cost, moderate hardness, high shear efficiency |

Medium and low alloy steel (Q345, 16Mn, etc.) | 6CrW2Si, Cr12MoV | Higher hardness and wear resistance to prevent edge chipping |

Stainless steel (201, 304, 316) | Cr12MoV, SKD11 | Corrosion resistance, anti-adhesion, and strong wear resistance |

High-strength steel, spring steel | SKD11, ASP23 | Extremely high strength requirements to prevent edge chipping |

Silicon steel sheet, cold-rolled sheet | Cr12MoV, powder metallurgy steel | High precision requirements and strong wear resistance |

Soft metals such as copper, aluminum, and aluminum alloys | T8, T10 | Moderate hardness to minimize surface damage |

Hot-rolled sheet, hot-sheared materials | H13, 5CrNiMo | Excellent high-temperature strength and resistance to thermal fatigue |

2) Choose according to frequency of use and work intensity

Frequency of use/operating environment | Recommended blade materials | Description |

Low frequency, occasional shearing | T8, T10, 9CrSi | Prioritizes cost control and ensures sufficient durability. |

Medium frequency, standard shearing | 6CrW2Si, Cr12MoV | Stable performance, balancing affordability and longevity. |

High frequency, heavy-duty shearing | SKD11, ASP23 | High wear resistance, long life, and crack resistance. |

High temperature shearing environment | H13 | High heat and deformation resistance, suitable for hot shearing. |

High precision requirements | SKD11, powder metallurgy steel | Excellent dimensional stability, not susceptible to wear and dulling. |

3) Select according to device type

Shearing machine types | Recommended blade materials | Features |

Conventional mechanical shearing machine | T8, T10 | General-purpose blade material, high cost-effectiveness |

9CrSi, 6CrW2Si | Large load capacity, smooth cutting | |

6CrW2Si, Cr12MoV, and H13K (4Cr5MoSiV1) | High precision, long life, reduced replacement frequency | |

Hot shearing machine | H13 (4Cr5MoSiV1) | High temperature resistance and strong resistance to thermal fatigue |

4) Notes

Blade hardness is not necessarily better:

- Higher hardness provides greater wear resistance, but also reduces toughness and is prone to chipping.

- The harder the material, the more rigorous the heat treatment, and the higher the price.

- The choice should be based on a balance between hardness and toughness.

For materials prone to “bite,” such as stainless steel and silicon steel, it is recommended to use:

- Cr12MoV or SKD11, which prevent sticking and are less prone to chipping.

- For applications requiring high tool life and inconvenient frequent tool changes, powder metallurgy steel (ASP23/ASP60) is an option, but it is more expensive.

Hot shearing environments:

- Ordinary blades such as T10 can cause shear failure or edge damage due to thermal deformation or annealing.

- H13 hot work die steel should be used.

4. Considerations for Blade Material Selection

When selecting blade material for a shearing machine, it’s important to comprehensively consider multiple factors, including the characteristics of the material being sheared, the operating conditions, compatibility with the equipment, and cost-effectiveness. The following are key considerations when selecting blade material:

1) Don't blindly pursue high hardness

Common Misconception: The belief that “the harder the blade, the better.”

Reality:

- Although high-hardness blades offer excellent wear resistance, they also suffer from poor toughness, increased brittleness, and the tendency to chip.

- A balance should be struck between hardness and toughness, especially when shearing high-strength steel or other hard materials.

Recommendations:

- For continuous, high-frequency shearing, choose a high-hardness material (such as Cr12MoV or SKD11).

- For occasional shearing or shearing softer materials, choose a medium-hardness, high-toughness material (such as T10 or 9CrSi).

2) Match the blade material to the material being cut

Different materials have different requirements for blades. Improper use can lead to premature blade wear, cracking, or poor cutting.

Material Type | Materials not recommended | Causes |

Stainless Steel | T10, 9CrSi | Susceptible to wear and chipping |

High Strength Steel | T10, Cr12 | Unable to withstand high shear stress |

Hot Shear | Ordinary alloy steel | Easily softened by annealing, losing shear strength |

Recommendation:

Hard materials (stainless steel, high-strength steel) → Choose high-wear-resistant grades such as Cr12MoV.

Hot materials → Choose hot-work die steels such as H13 (4Cr5MoSiV1).

3) Consider Equipment Type and Compatibility

Different shearing machines have different requirements for blade structure and performance:

- Mechanical shears have high speeds and high impact forces, requiring blades with higher toughness.

- Hydraulic shears offer smooth shearing and are suitable for wear-resistant blades.

- CNC plate shearing machineoffer high precision and require blades that resist deformation and exhibit greater wear resistance.

Recommendation:

- Before selecting a blade material, understand the equipment type and recommended standards.

- Compatibility of blade hardness, size, and the equipment’s adjustment system is crucial.

4) Combine frequency of use with cost budget

- High frequency of use → Choose a material with a longer lifespan (such as SKD11 or ASP23).

- Low frequency of use → Choose a material with a higher cost-effectiveness (such as T10 or 9CrSi).

Although high-end blades are more expensive, they require less frequent replacement, making them more economical in the long term.

Recommendation:

- Choose a blade based on a comprehensive evaluation of “material unit price × replacement frequency × downtime losses.”

5) Heat treatment quality is also important

Even for the same material, different heat treatment processes can significantly vary performance. Improper heat treatment can lead to insufficient blade hardness, excessive brittleness, and shortened blade life.

Recommendation:

- Purchase blades from reputable brands or experienced manufacturers.

- Ensure they have undergone rigorous heat treatment and tempering.

6) Pay attention to the quality of the sheared surface

If you have high requirements for the sheared edge (e.g., burr-free and deformation-free):

Choose a blade material with good toughness, a sharp edge, and uniform hardness.

Common materials include Cr12MoV, SKD11, and powder metallurgy steel.

5. Summary

Metal Shearing Machine Blade Material and Performance Comparison Table:

Materials | Hardness (HRC) | Abrasion Resistance | Toughness | Thermal Stability | Thermal Stability |

T10 | 58-62 | Medium | Low | Poor | Poor |

9CrSi | 58-60 | Good | Medium | Medium | Medium |

6CrW2Si | 60-62 | Good | Medium | Good | Good |

Cr12MoV | 58-60 | Very Good | Relatively good | Good | Good |

H13 | 50-55 | Medium | Good | Excellent | Excellent |

SKD11 | 58-62 | Very Good | Excellent | Very Good | Very Good |

ASP23 | 62-65+ | Excellent | Toughness | Excellent | Excellent |

Material selection summary table:

Requirements Priority | Recommended Materials |

Cost Priority | T10, 9CrSi |

Wear Resistance Priority | Cr12MoV, SKD11 |

Toughness Priority | 6CrW2Si, H13 |

High Temperature Resistance | H13, 5CrNiMo |

Extreme Life Requirement | ASP23, Powder Metallurgy Steel |

Summary of considerations for blade material selection:

Key Points | Recommendations |

Don’t blindly pursue hardness | Hardness and toughness require a balance |

Match the material being cut | Improper matching can lead to chipping |

Match the equipment | Structure, precision, and speed must be compatible |

Consider comprehensive cost considerations | High-end materials are more expensive but more durable |

Ensure heat treatment quality | Determines the true performance of a blade |

Observe cutting quality requirements | For higher precision, choose a higher-performance material |

The metal shearing machine blade material plays a crucial role in shear quality, blade life, equipment stability, and production efficiency. Choosing the right material not only ensures smooth, precise, and accurate shearing, but also significantly reduces the frequency of blade replacements and downtime.

If you are purchasing or replacing blades, please share your shearing material, thickness, equipment model and drawings, and shearing frequency information. I can provide you with more specific material recommendations.