Table of Contents

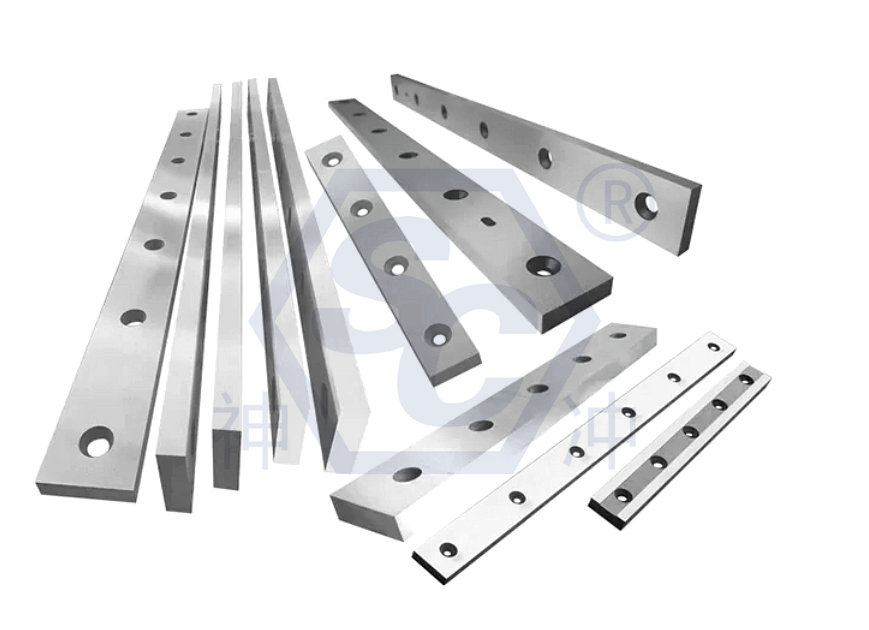

Plate shearing machine blades are one of the core components of a sheet metal shearing machine, directly determining cutting performance, processing quality, production efficiency, and equipment life. In fields such as sheet metal processing, machinery manufacturing, automotive, home appliances, and construction, the quality of the blades plays a decisive role in production results. The following is a detailed analysis of the importance of shearing machine blades.

1. The Importance of Plate Shearing Machine Blades

1) Key factors determining shear quality

A sharp blade with appropriate hardness ensures a smooth, burr-free, and crack-free shear surface.

Poor blade material or severe wear will result in:

- Excessive shearing burrs

- Deformation of the plate edge

- High workpiece scrap rate

Directly impacting the quality of subsequent processing steps such as welding, bending, and painting.

2) Impacting equipment stability

Low-wear blades with insufficient strength:

- Easily chip and crack during shearing.

- This can cause significant vibration and abnormal impact.

- In severe cases, it can damage critical components such as the blade holder and cylinder.

High-quality blades effectively protect the shearing machine structure and extend its lifespan.

3) Determining production efficiency and operating costs

Durable blades extend the blade change cycle, reducing downtime. Sharp blades offer low shearing resistance and high cutting speed, increasing production capacity.

Frequent blade changes increase:

- Production downtime

- Labor and commissioning costs

- Repair costs

4) Directly linked to the company's economic performance

Although high-quality plate shearing machine blades may be more expensive to purchase, they:

- Excellent shearing performance and reduced scrap. Long service life, saving replacement costs.

- Reduces equipment failures and maintenance costs.

- It is a key component with a one-time investment and long-term benefits.

5) Meets the needs of different processes and materials

For different materials (carbon steel, stainless steel, aluminum plate, high-strength steel, etc.), different thicknesses, and different processes (cold shearing, hot shearing), corresponding blade materials need to be configured.

Rational selection ensures cutting accuracy and reliability, meeting customers’ personalized processing needs.

Comparison of the role of the blade in the entire shearing system:

Components | Main Functions | Critical or not |

Shearing machine main frame | Provides support and transmission | Important |

Hydraulic system/drive system | Provides cutting power | Important |

Blades (upper and lower) | Directly completes the cutting action | Core critical component |

Control system | Controls cutting rhythm and length | Important |

Positioning device | Precisely feeds materials | Minor important |

Plate shearing machine blades are the direct execution component for the “cutting” action. Without a good blade, no matter how advanced other systems are, they cannot guarantee the final processing effect.

2. Consequences of Ignoring Blade Quality

Ignoring shearing blades quality often leads to a series of serious consequences, not only affecting shearing results but also causing equipment damage, reduced production efficiency, and even safety hazards. The following are the main consequences of ignoring blade quality:

1) Key factors determining shear quality

- Low-Sharpness and Insufficient Hardness: Uninterrupted and uneven cuts, requiring repeated shearing

- Excessive Blade Wear: Large burrs and rough cut surfaces

- Breaking or chipping of the blade: Sheet edges tear, bend, and become scrapped

- Incompatibility of Blade Material with Shearing Material: Sheet sticking, cracking, and shearing deformation

Consequences: Seriously impact product quality, leading to rework, returns, and customer complaints.

2) Increased Risk of Equipment Failure and Damage

- Poor-quality blades lack toughness and are easily brittle and break, causing shear shock to be transmitted to the machine body.

- Prolonged use of worn blades can subject the equipment to abnormal loads.

Uneven or deformed blade edges can cause:

- Uneven force on the tool holder

- Irregular wear of the piston rod or blade shaft

- Abnormal heating of the hydraulic system

Consequences: Shortened equipment life, increased repair costs, and, in severe cases, equipment downtime.

3) Significantly Reduced Production Efficiency

- Frequent Blade Replacement: Increased Downtime and Higher Maintenance Costs

- High Shearing Resistance: Slower Cutting Speed and Reduced Production Capacity

- Frequent Quality Issues: Require Secondary Processing or Scrapping, Slowing Production

Consequences: Limited Production Capacity, Delayed Delivery, and Impact on Customer Satisfaction and Company Reputation.

4) Increased Manufacturing Costs

- Although low-quality blades are inexpensive, they have a short lifespan and require frequent replacement.

- This leads to increased maintenance, material waste, and increased energy consumption.

- Indirect costs can even exceed the investment in high-quality blades.

Consequence: “Saving money on blades, but losing money on the production line”—a costly mistake.

5) Increased Safety Risks

- Broken blades can fly out and cause personal injury.

- Uncontrolled shearing can cause sheet material to slip or rebound, threatening operator safety.

- Unstable or deformed blades can increase the risk of accidents.

Consequences: Violating safety regulations can result in legal liability or even production suspension.

Recommendations:

- Preferably choose reputable brands or blade suppliers with quality certifications.

- Select blades of appropriate material and specifications based on the material being cut and the equipment being used. Regularly check blade wear and replace them promptly.

- Avoid using worn blades to reduce losses.

3. How to Choose the Right Shear Blade?

Selecting the right shear blade is key to ensuring shear quality, improving production efficiency, and extending equipment life. Plate shearing machine blades selection requires comprehensive consideration of factors such as the shearing material, shear thickness, frequency of use, and equipment type. The following is a systematic and practical guide to selecting shear blades:

1) Identify the Shearing Material

Different materials have different performance requirements for blades, which is the first step in selection.

Selection Analysis Table:

Materials Sheared | Recommended blade materials | Features |

Ordinary carbon steel (Q235, Q195) | T10, 9CrSi | Low cost, moderate hardness |

Low-medium alloy steel (Q345, 16Mn) | 6CrW2Si, Cr12MoV | High strength, excellent wear resistance |

Stainless steel (304, 201, etc.) | Cr12MoV, SKD11 | High hardness, corrosion resistance |

High-strength steel, silicon steel sheet | SKD11, powder metallurgy steel (ASP23) | Resists chipping and wear |

Copper, aluminum, aluminum alloys | T8, T10 | No material damage, low cost |

Hot shearing (hot-rolled plate) | H13 | Resists thermal fatigue and high-temperature shear |

2) Determine Shearing Thickness and Frequency

Selection Analysis Table:

- Thin plates (<3mm) can use conventional blades such as T10 and 9CrSi.

- Medium-thick plates (3–8mm) are recommended using Cr12MoV.

- Thick plates or high-strength plates (>8mm) are recommended using high-strength materials such as SKD11 and ASP23.

Frequency of Use:

- Low-frequency shearing → Cost-effective, choose T10 or 9CrSi.

- Medium-frequency shearing → Cost-effective, choose 6CrW2Si or Cr12MoV.

- High-frequency, high-intensity shearing → Wear-resistant SKD11 or powder metallurgy steel is more suitable.

3) Matching the Shearing Machine Type

Shearing machine types | Recommended blade materials | Description |

Mechanical shearing machine | T10, 9CrSi | Economical material sufficient for the job |

Hydraulic shearing machine | Cr12MoV, 6CrW2Si | Shear stability, long life requirements |

SKD11, ASP23 | High precision requirements, good stability | |

Hot shearing machine | H13 | High temperature resistance and thermal crack resistance required |

4) Combining cost and lifespan

Material | Cost | Lifespan | Applications |

T10 | ★ | ★★ | General shearing, low-frequency applications |

9CrSi | ★★ | ★★★ | Medium-frequency applications for ordinary steel plates |

Cr12MoV | ★★★ | ★★★★ | Stainless steel, heavy-duty shearing |

SKD11 | ★★★★ | ★★★★★ | High-strength steel, precision shearing |

ASP23 | ★★★★★ | ★★★★★★ | High-end manufacturing, high-volume production |

Recommendation:

If the short-term budget is limited, you can choose cost-effective materials. For long-term stable production, you should choose durable materials.

4. Summary

1) The Importance of Plate Shearing Machine Blades

- Determines Shearing Quality: Affects Shear Edge Smoothness and Accuracy

- Protecting Equipment Structure: Extends Machine Life and Reduces Failures

- Improves Production Efficiency: Reduces Blade Changes and Increases Shearing Speed

- Reduced Overall Costs: Reduces Hidden Costs Such as Downtime, Scrap, and Repairs

- Adapts to Diverse Needs: Adapts to Shearing Tasks of Different Materials and Processes

2) Practical Selection Steps

- Confirm the Shearing Material Type and Hardness

- Confirm Shearing Thickness Range

- Confirm Shearing Frequency and Continuous Operating Time

- Confirm Shearing Machine Model and Operating Mode

- Compare Blade Life with Budgeted Cost

- Selects Products from Reputable Manufacturers with Heat Treatment and Quality Assurance