Table of Contents

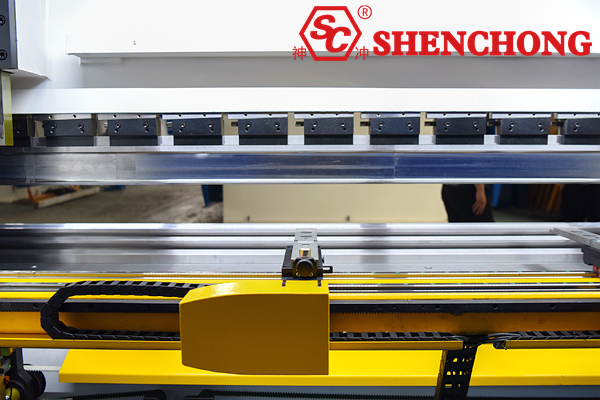

Poland Hybrid Servo Press Brake WDK 170T 3200MM 6+1 Axis CYBELEC CT15 adopts oil-electric hybrid drive system. Generally compared with traditional hydraulic systems, it is more energy-efficient, faster to respond and less noisy. The WDK series oil-electric hybrid CNC press brake machine is an advanced sheet metal processing equipment that integrates energy saving, high efficiency, intelligence and safety.

The machine adopts the latest generation of oil-electric hybrid drive technology, combined with high-performance CYBELEC CT15 CNC system and multi-axis servo control, which can meet the processing needs of high-precision, diversified and complex parts, and is widely used in sheet metal, cabinets, electrical appliances, automobiles and other industries.

1. Poland hybrid servo press brake technical parameters

1) General equipment parameter table (example):

Item | Parameters |

Nominal pressure | 170 tons |

Bending length | 3200 mm |

Column spacing | 2600 mm (customizable) |

Throat depth | 400 mm (reference value) |

Slider stroke | 200 mm (reference value) |

Opening height | 470 mm (including mold) |

Workbench height | 900 mm (ergonomic) |

Number of control axes | 6+1 axis (Y1, Y2, X, R, Z1, Z2 + V axis) |

Positioning accuracy | ±0.01 mm |

Repeat positioning accuracy | ±0.005 mm |

Drive mode | Hybrid servo system |

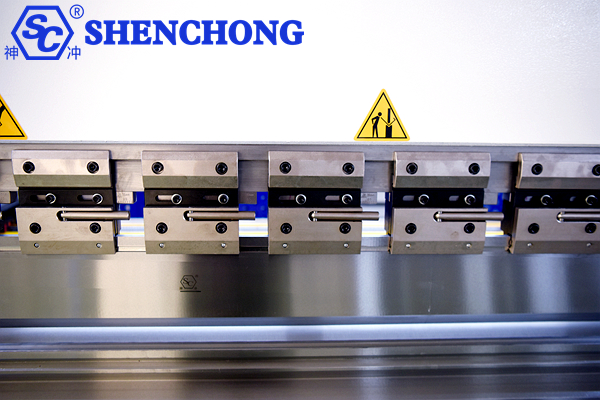

2) Structure and drive system features

Hybrid system:

- Energy saving and consumption reduction: Intelligently adjust power output according to actual work needs.

- Quick response: Servo pump control to increase the speed of upper and lower mold movements.

- Stable and quiet: Lower noise and less maintenance than traditional hydraulic systems.

High-strength integrated frame:

- Overall welded structure, aging treatment to ensure rigidity and long-term stability.

- Adopt high-precision linear guides and ball screws for higher precision and longer life.

2. Hybrid servo driving technology

- Energy Saving: Compared with traditional hydraulic systems, energy saving is up to 60% or more.

- Low noise: almost no noise when in standby and quieter when running.

- Fast response: servo control, high precision and fast speed.

- Less maintenance: extended hydraulic oil life, high system stability.

3. Control system: CYBELEC CT15

- Brand: Swiss CYBELEC

- Screen: 15-inch color touch screen

Functional features:

- Graphical programming interface, what you see is what you get.

- Support 3D bending simulation, automatic interference detection.

- Support angle compensation, mold library management.

- USB interface, support program import and export.

- Can connect to the network for remote diagnosis and maintenance.

4. Safety system: DSP laser protection

- High-sensitivity light curtain detection system.

- Automatic shutdown protection if a human body approaches the mold area during operation.

- Supports dynamic area recognition of upper and lower sliders to improve safety and efficiency.

- Meets EU CE standards

5. Core advantages of Poland oil-electric hybrid press brake machine

- Oil-electric hybrid drive: energy-saving, stable, and fast response.

- Multi-axis intelligent control: high-precision processing of complex parts.

- Strong structural rigidity: high stability for long-term work.

- Modular design: easy to upgrade and maintain.

- Support customization: The system and accessories can be configured according to customer needs.

Poland Hybrid Servo Press Brake WDK-170T/3200 is a new generation of intelligent, high-precision, and high-energy-saving sheet metal processing equipment. The equipment adopts an oil-electric hybrid drive system, combined with a high-strength frame structure and multi-axis servo control, which can achieve stable and efficient bending operations. It is widely used in the bending and forming of various materials such as stainless steel, carbon steel, and aluminum alloy.