Table of Contents

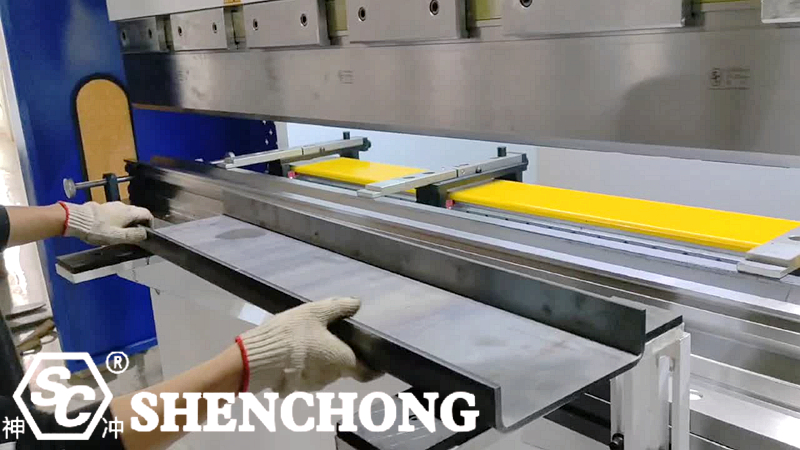

This SC WSK CNC Press Brake 250T 3200MM is a high-performance, energy-efficient single-servo pump-controlled bending machine, embodying the principles of “energy saving, high efficiency, and precision.” It utilizes single-servo pump-controlled energy-saving technology and is equipped with a 4+1-axis CNC system.

It boasts a maximum bending force of 250 tons and a bending length of 3200mm. Equipped with Shenchong’s independently developed EL15T touch screen CNC system, it is suitable for bending medium and heavy plates and precision sheet metal.

1. Core Configuration & Structural Features Of SC WSK CNC Press Brake 250T 3200MM

WSK CNC Press Brake 250T 3200MM Core configuration:

- Nominal Pressure: 2500 kN (250 tons)

- Bending Length: 3200 mm

- Controlled Axes: 4 + 1 (Y1, Y2, X, R + V-axis compensation)

- Main Drive: Single servo pump control system

- Main Motor: High-performance servo motor (energy-saving and quiet)

- Fluid System: Servo pump direct-drive closed-loop hydraulic system for fast response, low energy consumption, and low heat generation

- Construction: Integrally welded, tempered and stress-relieved for high rigidity and precision

- Guides and Screws: Imported or high-precision domestically produced ball screws + linear guides (X and R axes)

- Table Compensation: Hydraulic or mechanical V-axis deflection compensation

- Backgauge System: Electric control of the X and R axes for fast positioning and stable reliability

Frame and Structural Features:

- Unibody welded Q345 steel plate construction with high-temperature annealing for stress relief.

- Utilizing finite element analysis and structural optimization, the design ensures deformation resistance during long-term, intensive use.

- High-precision alignment of the slider and guide rail ensures smooth operation and ensures bending accuracy.

- The V-axis is equipped with a mechanical or hydraulic deflection compensation system to ensure consistent bending line shape.

2. System Control Highlights: SC EL15T CNC System

The EL15T is a high-end bending CNC system independently developed by SC, offering the following features:

- 15-inch high-definition touch screen with a user-friendly interface and simple operation

- Supports fast programming and simulation of 2D drawings, and real-time bending simulation

- Imports DXF drawings and automatically generates bending programs

- Built-in database for materials, molds, and bending process parameters

- Switchable Multiple languages interface, supports USB and Ethernet communication

- Supports remote maintenance and upgrades

Click here to know more about: SC EL CNC System

3. Advantages of the Single Servo Pump-Controlled Hydraulic System

- Energy Saving: Intelligently adjusts pressure and flow based on the slider’s real-time requirements, significantly reducing reactive power losses.

- Low Noise: The servo pump operates at reduced speed when not in operation, reducing overall machine noise by over 30%.

- High Response: Hydraulic action responds faster, improving bending efficiency.

- Precise Pressure and Speed Control: Excellent bending consistency and repeatability.

- Energy Savings: Compared to traditional fixed-displacement pump hydraulic systems, the overall machine saves 30-50% in energy.

4. Equipment Features

WSK CNC Press Brake Single Servo Pump Drive System:

- This system utilizes a high-response servo motor and a metering pump for on-demand oil supply, eliminating traditional throttling and overflow controls and resulting in a simpler system structure.

- This system achieves precise control and fast response throughout the entire bending process, while being energy-efficient and quiet, reducing energy consumption and heat generation.

4+1 Axis Fully CNC Configuration:

- Controlled axes include: Y1 and Y2 (slide up and down), X (back gauge forward and backward), R (back gauge up and down), and V-axis (deflection compensation).

- This system meets the high-precision bending requirements of complex workpieces with multiple angles and fold lines.

High-Strength Integrated Welded Frame:

- This machine is constructed from Q345 or higher steel plates, welded together and subjected to high-temperature tempering and stress relief treatment to ensure long-term deformation resistance.

- High torsional rigidity ensures precision and stability under heavy bending loads.

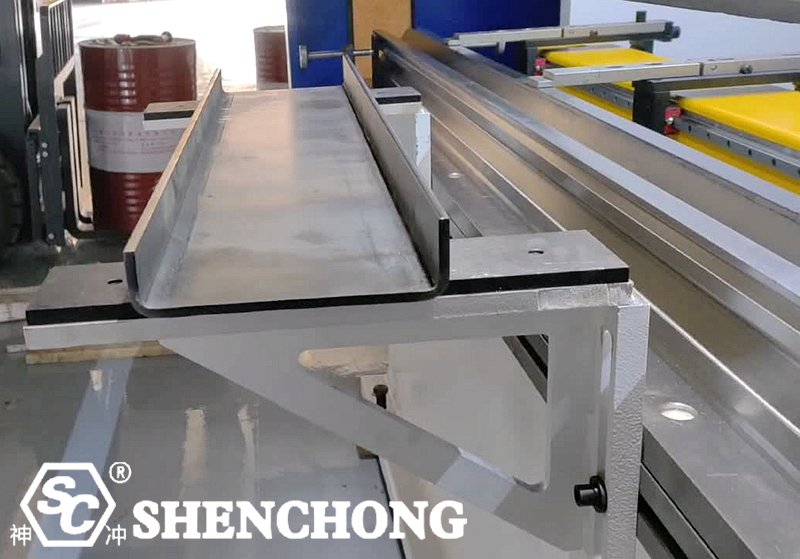

Precision Back Gauge System:

- This system utilizes a high-precision ball screw and linear guide system, driven by a servo motor.

- This system offers fast, stable, and high-precision positioning, making it suitable for high-volume production of precision products.

V-Axis Deflection Compensation System:

- Actively compensates for changes in lower die deflection, ensuring angle consistency throughout the entire bending length.

- Effectively resolves issues with long plate deformation and bending angle deviation.

5. Optional Configurations (Upgradeable upon request)

- Longer stroke, deeper throat, or C-shaped opening

- Upper and lower quick clamping system (mechanical, pneumatic, or hydraulic)

- Laser safety device (such as DSP or LazerSafe)

- Multi-axis backgauge system

- Automatic bending follower device

- Automatic loading and unloading system

- Robot arm linkage interface

6. Applications

- Various sheet metal fabrication plants

- Home appliance housings, kitchen appliances, telecommunication cabinets

- Chassis and cabinets, electrical control cabinets

- Elevators, stainless steel products

- Medium and thick plate bending and structural component manufacturing

If you would like to know the specific parameters and price of SC WSK CNC Press Brake 250T 3200MM EL15T 4+1 Axis, please contact us. We will prepare a detailed information for your reference.