Table of Contents

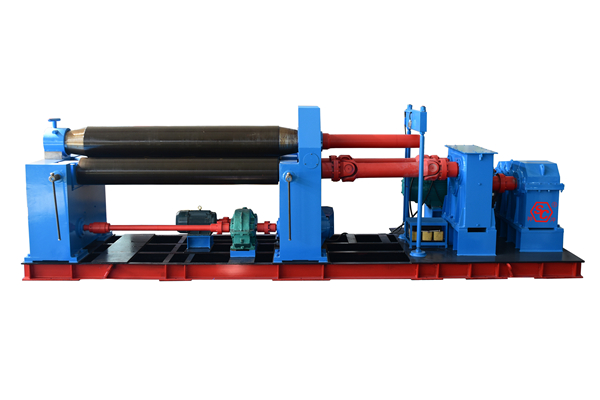

Three roll plate rolling machine is a kind of equipment that uses three working rollers to continuously bend metal plates to form cylindrical or curved parts. It is widely used in industries such as boilers, shipbuilding, machinery manufacturing, pressure vessels, and steel structures.

When purchasing a three-roller plate rolling machine, you need to consider the performance, purpose, material adaptability, degree of automation, and budget of the equipment. The following is a detailed guide to purchasing a 3-roller plate rolling machine.

1. Comprehensive introduction of three roll plate rolling machine

1) What is a three-roller plate rolling machine?

A three-roller plate rolling machine is a device that rolls metal plates (such as steel plates, stainless steel plates) into cylindrical, conical or other curved shapes by the relative movement of three rollers, so that they undergo plastic deformation under the action of force.

Three roll plate rolling machines are widely used in:

- Pressure vessel manufacturing

- Pipeline engineering

- Steel structure manufacturing

- Shipbuilding

- Chemical industry

- Aerospace

- Engineering machinery and other industries.

2) Basic structure

The 3-roller plate rolling machine is mainly composed of the following parts:

- Upper roller (active roller): usually located in the middle and upper part, providing the main driving force.

- Lower roller/side roller (driven roller): located at the bottom or side, can be raised and lowered, used to apply pressure to the plate.

- Main transmission device: drives the upper roller or two lower rollers to rotate.

- Lifting mechanism: adjusts the position of the lower roller or side roller to control the bending radius.

- Hydraulic system or mechanical system: used for roller lifting control.

- Electrical control system: used for overall operation and control, some are CNC/fully automatic systems.

3) Working principle of three-roller plate rolling machine

– Basic principle

The three-roller plate rolling machine mainly generates continuous three-point bending force on the metal plate between the three rollers to achieve bending and rolling of the metal plate.

– Working process

Feeding and positioning:

The plate is fed between the upper and lower rollers and aligned.

Adjust the position of the lower roller or side roller according to the required rolling radius.

Pressure pre-bending (if pre-bending function is available):

One end is first pressed to remove the straight section at the end of the plate to achieve “pre-bending”.

– Rolling

The upper roller or lower roller starts to rotate, driving the plate to move along the roller surface.

Under the continuous pressure of the side roller or lower roller, the plate bends at multiple points, and finally forms the required circle or arc.

– Unloading and unloading

After rolling is completed, the rolled workpiece is removed by tipping the upper roller or removing the support device.

2. Classification of three-roller plate rolling machines

1) Basic classification list

Based on the roller arrangement and movement characteristics, three-roller plate rolling machines mainly have the following types:

Type | Features | Scope of application |

Symmetrical three-roller plate rolling machine | The middle roller moves up and down, and the rollers on both sides are fixed and rotated | Simple structure, suitable for small and medium thickness plates |

Asymmetrical three-roller plate rolling machine | The upper roller is fixed, and the lower roller and side rollers move | Can achieve end pre-bending, suitable for thin plates |

Level down three-roller plate rolling machine | The lower roller moves along the arc trajectory to improve the pre-bending accuracy | Suitable for medium and thick plates |

Universal three-roller plate rolling machine | All three rollers can move, powerful functions | High degree of automation, suitable for large engineering projects |

2) Common types of three-roller plate rolling machines

- Classification by roller arrangement and movement mode

Symmetrical three-roller plate rolling machine

Structural features:

- The upper roller is the active roller and can move up and down.

- The two lower rollers are fixed and driven by the motor to rotate.

Advantages:

- Simple structure and low manufacturing cost.

- Applicable to small and medium thickness plates.

Disadvantages:

- No pre-bending function, and the two ends of the plate need secondary processing.

- Scope of application: General rolling occasions, such as medium thickness carbon steel plate processing.

Asymmetric three-roller plate rolling machine

Structural features:

- One lower roller is the active roller, and the other roller and the upper roller can move.

- End pre-bending can be achieved.

- Sometimes it is also called “primary pre-bending type”.

Advantages:

- High rolling accuracy.

- Poor pre-bending ability.

Disadvantages:

- Poor adaptability to thick plates.

- Relatively complex structure.

- Scope of application: Thin plate rolling, light manufacturing industry.

Level down three-roller plate rolling machine

Structural features:

- The upper roller is fixed, and the two lower rollers rise and fall along the arc trajectory.

- Apply hydraulic drive.

- The bending points always maintain a reasonable distance to improve the rolling quality.

Advantages:

- High rolling accuracy and reasonable force distribution.

- Suitable for thick plates or high-strength steel plates.

Disadvantages:

- The cost is relatively high.

- Scope of application: thick plate rolling occasions such as shipbuilding, boilers, and high-pressure vessels.

Universal three-roller plate rolling machine (variable geometry type)

Structural features:

- All three rollers can be moved.

- High level of automation control, often equipped with CNC system.

- Multifunctional design, can roll special-shaped curved surfaces.

Advantages:

- Strong adaptability.

- Pre-bending and forming are completed at one time.

- Can be connected to the Industry 4.0 system.

Disadvantages:

- High cost and complex maintenance.

- Scope of application: heavy industry, large component manufacturing, complex structure rolling tasks.

- Classification by driving mode

Type | Drive mode | Features |

Mechanical three roll plate rolling machine | Gear transmission + screw adjustment | Traditional structure, suitable for light loads |

Hydraulic three roll plate rolling machine | Hydraulic cylinder drives the roller to move | Strong power, suitable for thick plates |

- By control system

Control mode | Features |

Manual control | Suitable for simple processing without high requirements |

Digital display control (NC) | Can be set and repeated, suitable for small and medium batch production |

CNC control (CNC) | High degree of automation, high precision, can be linked with CAD/CAM |

Fully automatic intelligent control | High-end equipment, suitable for large-scale automated workshops |

If you tell us the specific parameters of the plate you are processing (such as: material, thickness, width, whether it is mass production), we can recommend the most suitable three-roller plate rolling machine type and model for you.

3. Advantages and limitations of three-roller plate rolling machine

As a common plate rolling equipment, the three-roller plate rolling machine is widely used in the field of metal forming. It has a relatively simple structure and flexible operation, but it also has certain limitations. The following is an analysis of the advantages and limitations of the three roll plate rolling machine:

- Advantages of three-roller plate rolling machine

Simple structure and high cost performance:

- Especially the symmetrical and asymmetrical three-roller plate rolling machines, which have mature structures and low costs.

- Easy to repair, easy to maintain and maintain.

Wide range of application:

- Can process a variety of metal materials such as carbon steel, stainless steel, aluminum plate, etc.

- Suitable for manufacturing common parts such as cylinders, cones, and curved plates.

A variety of control methods are available:

- From manual control to digital display and CNC control, the appropriate configuration can be selected according to different needs.

- The automation level can be expanded to meet different production requirements.

Flexible operation and easy adjustment:

- By adjusting the position of the lower roller or side roller, the radius of the roll can be controlled.

- Some models have the function of end pre-bending to improve the accuracy of the finished product.

Small footprint:

- Compared with four-roller or large universal plate rolling equipment, three-roller plate rolling machine has more advantages in space utilization.

- Limitations of three-roller plate rolling machine

Limited end pre-bending ability:

- Especially for traditional symmetrical three-roller plate rolling machine, straight edges will remain at both ends of the plate during rolling.

- It needs to be assisted by artificial flame pre-bending or other equipment (such as hydraulic pre-bending machine).

Limited processing of thick plates:

- Conventional mechanical three-roller plate rolling machine is suitable for thin plates to medium and thick plates (≤16mm).

- For high-strength steel or ultra-thick plates, there may be problems such as insufficient rolling and difficult deformation control.

Limited one-time forming accuracy:

- Most three-roller plate rolling machines require repeated adjustments during the rolling process.

- It is impossible to complete high-precision rolling in one time, especially in symmetrical models.

Conical rolling is difficult:

- Ordinary three-roller machines are complicated to operate when processing conical cylinders, and special skills or equipment customization are required.

- In contrast, four-roller or universal three-roller plate rolling machines have more advantages in this regard.

Some types have low automation:

- Manual or mechanical equipment relies heavily on operator experience.

- Not suitable for automated production lines that require high efficiency and high consistency.

4. How to choose a three-roll plate rolling machine?

When choosing a 3-roll plate rolling machine, you need to make a comprehensive assessment based on your own production needs, processing material characteristics, budget, and requirements for automation.

1) Clarify processing requirements

Before selecting a model, sort out the following key parameters

- Maximum plate thickness: determines the rolling tonnage of the required equipment (the larger the machine, the stronger the capacity).

- Maximum plate width: affects the roller length and equipment size.

- Material type: Different materials have different tensile strengths, such as stainless steel requires greater pressure.

- Whether pre-bending is required: Some products require end pre-bending, and you need to consider whether the equipment has this function.

- Whether to process conical parts: Ordinary symmetrical plate rolling machines are not suitable for processing conical cylinders.

- Output and automation requirements: determine whether to purchase CNC equipment to improve efficiency and consistency.

2) Choose the appropriate plate rolling machine type

Match the appropriate machine type according to the processing characteristics:

Application scenarios | Recommend models | Control mode | Notes |

Thin plate, conventional cylinder processing | Asymmetric three-roller roll | Manual or digital display | With pre-bending function, high precision |

Medium and thick plate conventional rolling | Level down three-roller roll | Hydraulic or CNC | Strong force, stable structure, suitable for industrial production |

Large components/mass production | Universal three-roller roll | CNC | High cost, strong automation |

Conical parts processing | Special conical plate rolling machine/universal machine | Hydraulic/CNC | Ordinary three-roller machine is not recommended |

Limited budget, low precision requirements | Symmetrical mechanical plate rolling machine | Manual/electric | Low cost, suitable for simple rolling |

3) Key technical parameters to pay attention to

- The maximum roll thickness and width should be greater than your actual needs, leaving a 20% margin.

- The upper roller diameter and motor power directly determine the rolling capacity and energy consumption.

- Rolling speed: If it is mass production, the speed should be fast and efficient.

- Roller material and heat treatment: high-strength alloy steel, the surface should be quenched to improve wear resistance.

- Lower roller/side roller adjustment method: hydraulic adjustment is more stable and has higher precision.

- Bearing and guide rail structure: related to equipment life and accuracy retention ability.

4) Control system and operation mode selection

- Manual control: low cost, suitable for skilled workers to operate, but low efficiency

- Electric + digital display control: convenient operation, suitable for medium batch and repeated processing

- CNC (NC) or CNC system: high automation, can realize automatic pre-bending, memory program and other functions, suitable for high precision and batch requirements

5) Brand and after-sales service considerations

Recommendations:

- Brand reputation: mature brands and well-known manufacturers are preferred.

- After-sales service: whether on-site installation, commissioning, operation training, and warranty period are provided.

- Spare parts supply: whether fast and continuous parts support can be provided.

- Customer cases: refer to the feedback from users in the same industry to confirm stability.

6) Purchase tips

- On-site test machine: let the manufacturer process samples to verify the rolling accuracy, plate end quality, and operation smoothness.

- Pay attention to the weight and rigidity of the equipment: heavy structures are more durable and stable than light machine tools.

- Pay attention to transportation and installation requirements: confirm whether freight, basic drawings, and hoisting plans are included.

- Sign a technical agreement: list parameters, functions, delivery dates, after-sales, etc. to avoid disputes.

7) Common misunderstandings reminder

- Only look at the price: cheap equipment may have poor roller materials, welding quality, and control systems, resulting in frequent maintenance.

- Ignore the influence of plate material: stainless steel, high-strength steel, etc. have much higher requirements for equipment than ordinary carbon steel.

- Insufficient reserved capacity: do not choose a model that just meets the needs. It is recommended to select a model at 120% capacity.

5. Summary

- Key factors to consider when purchasing a three-roll plate rolling machine

1) Plate thickness and width

- When selecting equipment, it is necessary to match the maximum thickness and width of the processed plate.

- Leave a certain safety margin to ensure long-term stable operation of the equipment.

2) Material type

- Different materials such as steel, stainless steel, and aluminum plates have different requirements for roller rigidity and drive power.

- For high-strength steel, a plate rolling machine with a higher tonnage should be selected.

3) Pre-bending function

- Ordinary three-roll plate rolling machines cannot achieve end pre-bending.

- An asymmetric structure with pre-bending function or a structure with a clamping device must be selected.

4) Control system

- Manual control: suitable for occasions with low precision requirements.

- Digital display control (NC)/CNC control (CNC): suitable for mass production, improving precision and efficiency.

5) Drive mode

- Hydraulic drive: large bearing capacity and smooth operation.

- Mechanical drive: simple structure, suitable for light tasks.

6) Structural material and quality

- The main steel structure should be made of Q235 or above.

- Check details such as welding process, painting, and anti-rust treatment.

- Recommended configuration suggestions (based on usage)

Application | Recommended types | Control mode | Notes |

General workshop processing | Symmetrical mechanical type | Manual/electric | Economical and practical |

Stainless steel bending and coiling | Asymmetric hydraulic type | Digital display control | Improve efficiency and reduce rework |

Thick plate rolling (over 10mm) | Level-down hydraulic type | CNC | High precision and high strength |

Automated batch production | Universal three-roller CNC type | Fully automatic CNC | Large investment and high efficiency |

- Purchase suggestions and precautions

- Choose a reputable manufacturer: give priority to brands with mature technology and perfect after-sales service.

- Test machine verification: it is recommended to conduct a test roll before purchase to test the equipment accuracy and operation stability.

- Investigate after-sales service: such as whether on-site commissioning, maintenance, and operation training are provided.

- Confirm the supply of wearing parts: such as whether bearings, hydraulic parts, electronic control systems, etc. can be quickly replaced.

- Whether customized services are provided: for special plates or non-standard size rolling requirements.

If you provide specific processing requirements (plate thickness, plate width, material, whether pre-bending is required, budget, etc.), we can help you further select suitable models or give configuration suggestions.