Table of Contents

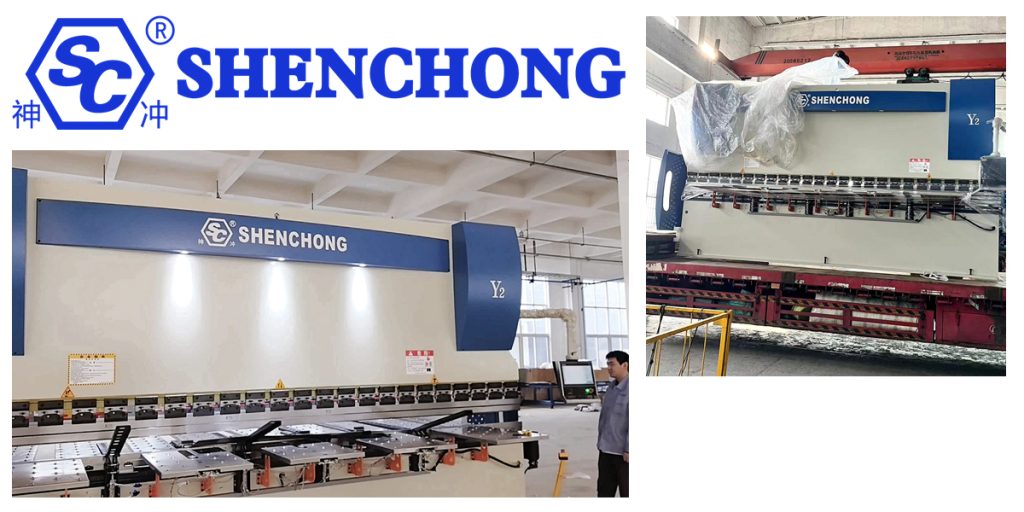

SC WSK CNC Press Brake 125t 5000 is a medium-sized CNC hydraulic servo bending machine used for sheet metal bending. It is suitable for bending steel plates, stainless steel, aluminum plates, and other metal materials.

The maximum work piece width is approximately 5000 mm. It is suitable for industries such as machinery manufacturing, sheet metal processing, transportation equipment, enclosure manufacturing, and structural component production.

1. Machine Structure And Drive Method Of WSK Servo CNC Press Brake Machines

1) Integral Welded Bed

- The WSK CNC servo press brake machine frame is a one-piece welded steel plate structure, tempered to eliminate welding stress.

- High rigidity and high stability, which is beneficial for maintaining accuracy during long-term repeated processing.

2) Drive Method

WSK CNC servo bending machines typically use a main motor servo control:

- The main servo motor drives the hydraulic pump for closed-loop control of pressure and speed, improving energy efficiency and accuracy.

- It offers significant energy savings compared to traditional electro-hydraulic systems (energy saving rate of approximately 60%).

- It operates with low noise and stable oil temperature, suitable for long-term continuous operation.

2. SC WSK CNC Press Brake 125T 5000 Typical Technical Parameters

Functions | Reference values |

Rated bending force | 125 tons (1250 kN) |

Bending length | Approx. 5000 mm (actual options 3200 mm / 4000 mm / 5000 mm) |

Slider stroke | ~ 120 – 150 mm (adjustable) |

Maximum opening height | ~ 350 – 450 mm |

Throat depth | ~ 350 – 450 mm |

Drive power | ~ 7.5 – 15 kW |

CNC system | SC EL15T |

3. Advantages Of SC WSK Single Servo Press Brake

SC WSK CNC Press Brake 125t 5000 is a medium-sized CNC hydraulic/servo-driven bending processing equipment with the following advantages:

- Robust structure, suitable for stable processing of 5-meter long parts

- Precise CNC multi-axis positioning

- Mature and user-friendly CNC system

- Powerful bending force and long bending length

- Energy-efficient servo drive system

- Flexible configuration and reliable structure

- Suitable for batch and medium-to-large workpiece bending processing

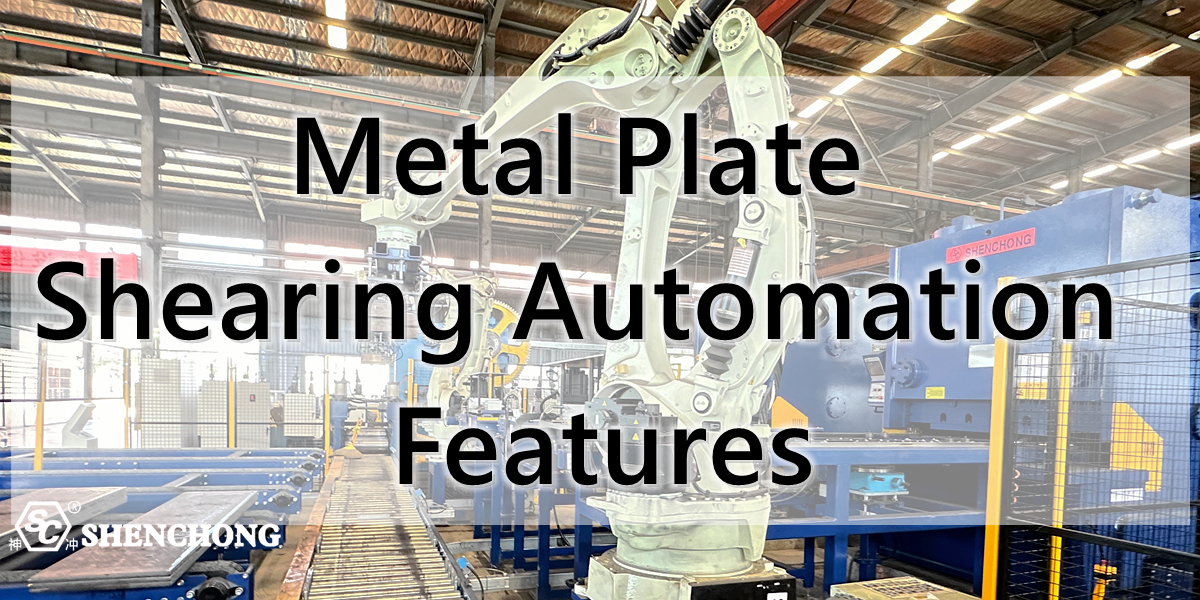

- Highly expandable CNC system (robot, follow-up material handling, automation)

4. Processing Capacity Reference (Carbon Steel)

CNC press brake 125t 5000mm bending force analysis table:

Materials | Bending capacity (reference) |

Q235 carbon steel | 4–5 mm × 5000 mm |

Stainless steel | 2–3 mm × 5000 mm |

Aluminum plate | 6–7 mm × 5000 mm |

Actual capability is closely related to the V-shaped opening size of the mold and the bending method.

5. Typical Application Industries

- Electrical cabinets/distribution boxes

- Elevators, curtain walls, architectural metal

- Construction machinery sheet metal

- Ventilation ducts and equipment housings

- New energy equipment racks

The WSK 125T 5000 mm CNC press brake machine is a high-performance CNC bending machine designed for processing medium to large-sized sheet metal parts, specifically for high-precision bending of long sheet metal. The machine features a robust structure and a mature control system, maintaining stable accuracy over long periods. It is widely used in the large-scale production of electrical cabinets, construction machinery, building curtain walls, new energy equipment, and various sheet metal structural components.

Optional features include laser safety protection, follow-up material support, and robotic bending systems, enabling customers to build safe, efficient, and upgradeable modern sheet metal bending production lines that balance precision, efficiency, and long-term investment value.