Table of Contents

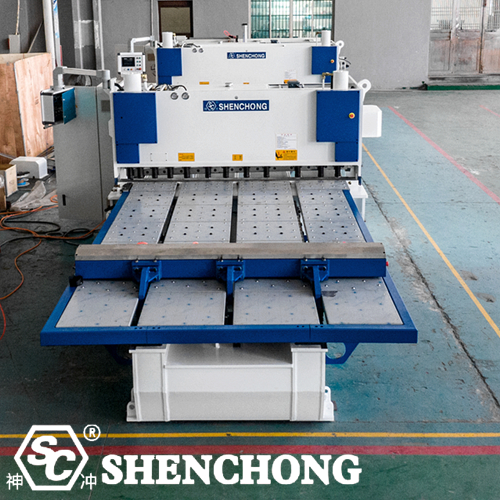

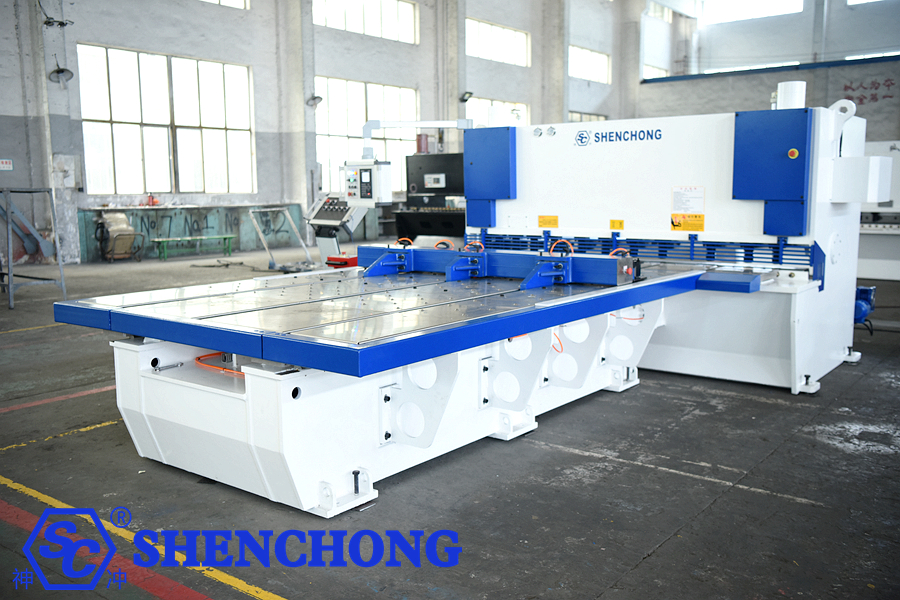

CNC Front-feeding shearing machine is traditional plate shearing machine with an automated front-feed mechanism. This automatically feeds the sheet metal into the shearing position according to the set size, achieving high-efficiency and high-precision shearing. They are commonly used in industries such as sheet metal processing, automotive manufacturing, home appliance manufacturing, construction machinery, and fuel cell bipolar plates.

Compared to traditional shearing machines, the main features and advantages of front-feeding shearing machines lie in automation, precision, and continuity. A detailed analysis is provided below.

1. What is a CNC front-feeding shearing machine?

1) Definition

A front-feeding plate shearing machine is an automated machine that integrates a hydraulic shearing machine, a servo feed system, and a CNC control system.

It uses a front-feed mechanism to feed a full sheet of metal into the shearing area, where it is sheared in sections to the desired length until the entire sheet is processed.

2) Components of the Front-Feed Shearing Machine

The hydraulic guillotine shear machine:

- Provides the power for shearing the sheet.

- The shearing thickness and width depend on the machine model.

Front feed mechanism:

- Typically utilizes a servo motor + ball screw/rack and pinion drive.

- It provides automatic positioning, clamping, and feeding functions.

- Programmable control enables automated multi-stage feeding and shearing.

CNC/PLC system:

- Controls feeding accuracy and synchronizes shearing.

- Can store multiple shearing process programs.

- The clamp and guide rails ensure smooth and accurate sheet feeding.

3) Working Principle

- The sheet is placed on the feed platform.

- The front feed mechanism clamps the sheet and feeds it along the set stroke.

- When the sheet reaches the set position, the shearing machine begins pressing down to cut.

- After completing one shearing cycle, the machine automatically enters the next cycle until the entire sheet is slit.

2. Features of Front-Feed Shears

CNC Front-feeding shearing machine integrate an automatic front-feed system (typically a servo drive + screw/rack and pinion or roller) with a traditional gate/swing shear, achieving integrated automatic positioning, clamping, feeding, and shearing. They are suitable for batch, fixed-length, or multi-section cutting.

Core Features:

- Automatic Feeding: Continuously feeds material to preset dimensions, reducing manual alignment and handling.

- High-Precision Positioning: Servo/encoder closed-loop control achieves positioning accuracy of ±1mm for thin sheet metal (depending on machine model and operating conditions).

- Programmable Batch Processing: The CNC/PLC can store multiple shearing programs, supporting continuous cutting of multiple processes.

- Clamping and Support System: Automatic clamping, adjustable backgauge, and side guides ensure material stability.

- Human-Machine Interface and Software Integration: Some models support integration with nesting/nesting software, enabling direct generation of cutting plans from the cutting diagram. Modular Expansion: Optional peripherals include extended feeding, reversing, scrap conveying, and automatic palletizing.

1) Automated Feeding

The servo motor-driven feeding mechanism enables precise feeding and positioning of plates.

Multiple length settings are available, enabling multiple continuous shearing operations on a single plate.

2) CNC Control

Feeding and shearing processes are controlled by a PLC or CNC system.

Parameterized programming is supported, allowing for storage of frequently used processes to reduce repetitive settings.

3) High-Precision Feeding Mechanism

Employs a ball screw or rack-and-pinion drive for high positioning accuracy (typically within ±0.1mm).

A clamping mechanism ensures plate straightness and stability.

4) Highly Integrated with the Shearing Machine

The front feeding system seamlessly integrates with the hydraulic gate/swing shears for coordinated operation.

Easy loading and unloading, with a relatively compact footprint.

5) Highly Adaptable

Compatible with a variety of plate types, including carbon steel, stainless steel, and aluminum.

Suitable for automatic unloading of thick, medium, and thin plates.

Key Technical Points (Key Performance Factors):

- Feeding Accuracy: Determined by the servo + encoder, transmission error, and guideway and fixture rigidity.

- Clamping Method and Force: Insufficient clamping force can cause material slippage, while excessive force can cause deformation.

- Stroke/SpeedMatching: The feed stroke and acceleration/deceleration profile must match the cutting cycle to avoid jams and waiting.

- Blade Gap:Blade adjustment directly impacts cut quality and die life.

- Backgauge System: Back gauge positioning accuracy affects length stability.

- Control Program and Human-Machine Interface: Usability impacts switching efficiency and operator error rate.

- Material Handling Capacity: Maximum width, maximum thickness, and materials with high tension/elasticity (such as thin stainless steel) require specific configurations.

- Scrap and Reversal Handling: Scrap management is critical in mass production, as failure to do so can impact cycle time and safety.

Maintenance And Using Life:

- Daily: Keep guideways clean and lubricate regularly, and inspect and tighten fixtures and drive fasteners.

- Periodic: Detect and sharpen/replace blade wear, replace hydraulic oil and filters, and calibrate servo system parameters.

- Spare Parts: A spare parts strategy should be in place for blade sets, backgauges, cylinder seals, sensors, and servo drives.

- Training: Operators and frontline maintenance personnel should receive training on blade gap adjustment, clamping force adjustment, and emergency response.

- Proper maintenance can significantly extend machine tool life and maintain accuracy (typical maintenance intervals include daily, monthly, and annual inspections).

Selection Checklist:

- Specify material type (carbon steel/stainless steel/aluminum), maximum thickness, plate width, batch size, and length distribution.

- Required feeding accuracy and finished product tolerance (e.g., ±1mm/±0.5mm).

- Projected maximum piece length and minimum cut length (influencing feeding mechanism design).

- Requirement for integration with nesting/unloading software or upstream automation (bending/punching presses).

- Expected shifts and utilization (influencing durability and cooling/maintenance configuration).

- Safety and Compliance: Requirements for safety guards, light barriers, emergency stops, CE certification, etc.

- Budget and spare parts availability: Blades, hydraulic components, servo compressors.

3. Advantages of Front-Feed Shearing Machines

- Improve Production Efficiency

- Automatically completes feeding and positioning, eliminating manual repetitive alignment.

- A single loading allows for multiple continuous cuts, significantly reducing production cycle times.

- Ensures Cutting Accuracy and Consistency

- The servo system ensures accurate feeding dimensions.

- Each cut has minimal error, making it suitable for high-precision part processing.

- Reduces Labor Costs and Labor Intensity

- Workers only need to load and unload the plates, eliminating frequent alignment operations.

- This is particularly effective for large and heavy steel plates, saving effort and time.

- Improve Production Safety

- Stay away from the cutting area, eliminating potential safety hazards associated with manual feeding.

- Reduced Accidents Caused by Operator Errors.

- Suitable for Mass Production and Intelligent Manufacturing

- Can be integrated with automated loading and unloading and storage systems to create a flexible production line.

- Can be integrated into smart manufacturing workshops to improve overall automation.

- Saving Materials

- High-precision cut-to-length cutting reduces material waste due to errors.

- Optimizes plate utilization.

Front-feed shearing machine vs. traditional shearing machine

Comparison table of front-feed shearing machine vs. traditional shearing machine:

Comparison Dimensions | Traditional shearing machines | Front-feed shearing machine | Differences and Advantages |

Feeding Method | Manual feeding and positioning | Automatic servo feeding, program control | Automation replaces manual labor, offering higher efficiency and precision |

Operator | Requires at least two people (feeding and operation) | One-person operation | Reduces labor intensity and reduces labor intensity |

Production Efficiency | Low efficiency per shearing operation, long positioning time | Continuous feeding, automatic cycle shearing | Increases efficiency by 2-5 times, making it suitable for mass production |

Cutting Accuracy | Reliant on manual positioning, large error (±1-2mm) | Servo control, low tolerance (±0.1-0.3mm) | Higher precision and better product consistency |

Safety | Manual approach to the blade, high risk | Automatic feeding, keeping personnel away from the blade | Significantly improved safety |

Level of Intelligence | No programming, only mechanical operation | Programmable control, multiple data storage | Quickly switches between tasks, reducing changeover time |

Application Scenarios | Suitable for small batches, low precision, and low labor costs | High-volume, fixed-length, high-precision production, short lead times | Front-feed shearing machines are more suitable for modern sheet metal manufacturing |

Management and Traceability | No data logging | CNC system records shearing data | Facilitates process management and cost accounting |

Investment Cost | Low price | High equipment price | High initial investment, but higher long-term ROI |

- Traditional shearing machines are suitable for small batches, low precision requirements, and low sensitivity to labor costs.

- CNC Front-feeding shearing machines offer comprehensive advantages in efficiency, precision, safety, and intelligence, making them more suitable for large-scale, intelligent sheet metal production.

4. Summary

The most prominent feature of the CNC front-feeding shearing machine is “automatic feeding + high-precision shearing.” Its advantages include improved efficiency, guaranteed accuracy, and reduced manual labor and safety risks, making it ideal for mass-produced, standardized sheet metal cutting.

Features and Advantages:

- High Efficiency: Automatic feeding eliminates manual repositioning of the sheet metal.

- High Precision: Servo-controlled, feeding accuracy reaches ±1mm.

- Reduced Labor Intensity: Reduces manual handling and alignment.

- Improved Safety: Workers are further away from the blade, reducing the risk of accidents.

- Suitable for mass production: Continuous feeding and shearing are possible.

Applications:

- Sheet metal batch cutting: Steel, stainless steel, aluminum, etc.

- New Energy Industry: Shearing of fuel cell bipolar plates and battery casings

- Automotive/Home Appliance Industry: Batch cutting of panels and sheet metal casings

- Engineering Machinery: Pre-processing of thick plate parts.