Table of Contents

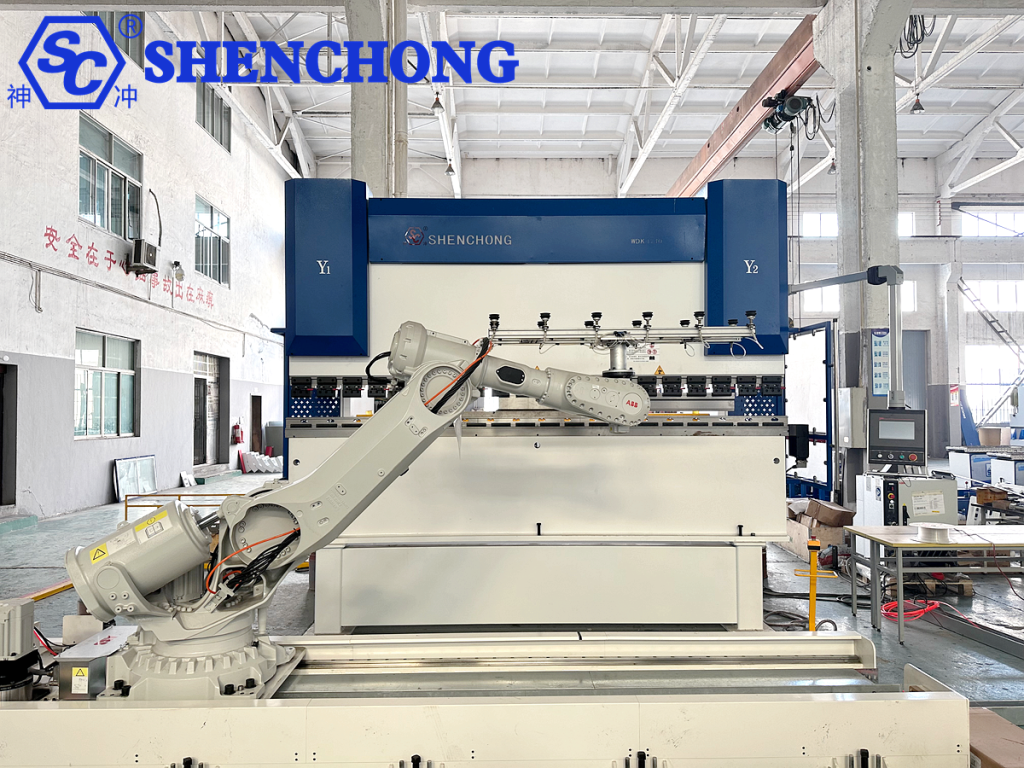

SC robot bending cell typically refers to an automated bending production system consisting of an industrial robot, a CNC press brake, and related automated auxiliary devices. It combines the robot and press brake to automatically load and unload, position, bend, and stack sheet metal parts, significantly improving production efficiency and consistency.

1. Components Of Robot Bending Cell

SC robotic bending cell is an automated bending solution that combines a CNC press brake with an industrial robot. It is primarily used for flexible, mass-produced sheet metal production.

1) Core Equipment

- CNC press brake: Responsible for sheet metal bending (typically a hybrid or servo press brake).

- Industrial robot: Mostly a six-axis robot, responsible for gripping, turning, positioning, and stacking work

2) End-of-line fixtures

- Vacuum cup fixtures: Suitable for thin and large sheets.

- Robotic grippers: Suitable for small and irregularly shaped parts.

- Combination fixtures: Compatible with workpieces of varying sizes.

- These fixtures must be customized based on the sheet material, weight, and shape to ensure gripping stability.

3) Auxiliary Equipment

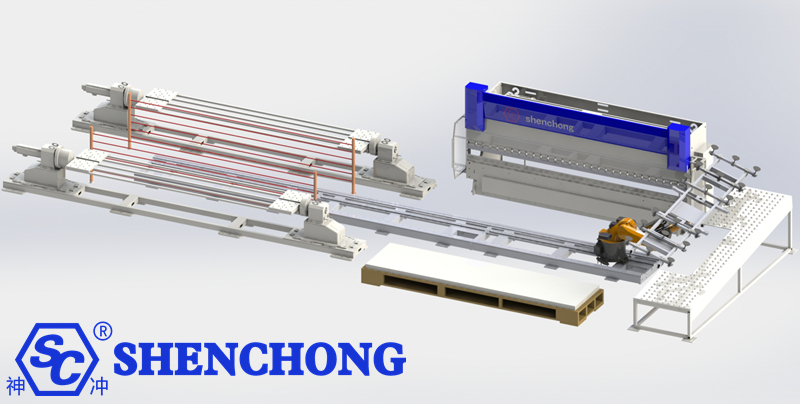

- Loading and unloading system

- Raw material storage/loading platform: Stores sheets to be processed, and robots or automatic loading devices retrieve them.

- Finished product unloading area/stockroom: After bending, the robot deposits the workpieces into designated locations.

- Positioning and Correction Devices

- Auxiliary Positioning Device: Ensures accurate positioning of the sheet metal before it enters the press brake.

- Vision System (Optional): Used to identify sheet metal position and angle to prevent error accumulation.

4) Safety Protection System

Safety light barriers, fences, laser scanners, etc. ensure operator safety.

Protective doors/safety interlocks prevent accidental entry into hazardous areas.

5) Control System And Software

- Robot Control System: Responsible for motion trajectory, gripping, and flipping operations.

- Press Brake CNC System: Controls bending depth, angle, and sequence (e.g., ESA, Delem, EL15T).

- Integrated Management Software: Enables linkage between the robot and press brake, automatically generating bending process programs.

2. Robotic Bending Workflow

The workflow of a robot bending cell is generally divided into the following main steps (using automated sheet metal bending as an example):

1) Sheet Loading

The sheet metal to be bent is removed from an automated material storage, loading cart, or robotic arm and delivered to the press brake station.

The robot typically grasps the sheet metal using vacuum cups, magnetic clamps, or mechanical grippers.

During the loading process, the sheet metal is positioned to ensure precise alignment between the workpiece and the press brake.

2) Sheet Positioning and Alignment

After the sheet metal is delivered to the press brake worktable, it undergoes baseline alignment using locating pins/photoelectric sensors.

The system verifies that the sheet metal size and thickness match the process program.

3) Bending

Robot Collaborative Mode:

The robot grasps the sheet metal according to the bending sequence and coordinates the movement of the upper and lower dies of the press brake.

During the bending process, the robot automatically flips, rotates, or repositions the workpiece to ensure continuous completion of multiple bends.

For large or heavy workpieces, the robot can provide follow-up support to prevent sheet metal deformation.

4) Workpiece Flipping and Secondary Bending

If a workpiece requires multiple bends, the robot will transport and flip the workpiece, placing it on the press brake die for the next step.

During the multiple-bending process, the robot and press brake are synchronized via a program to ensure accurate bend angles and positions.

5) Finished Product Unloading and Stacking

After bending, the robot removes the finished workpiece and places it in the finished product area or on automated racks.

The robot can sort and stack the workpieces based on production requirements (e.g., by batch, process, or shape).

6) Quality Inspection (Optional)

In-line inspection functions can be configured within the automated cell, such as:

- Bend angle measurement

- Dimensional inspection

- Surface quality monitoring

- Defective parts are automatically rejected.

3. Features And Advantages Of Robotic Bending Cells

1) Automation and Unmanned Operation

Robots can replace manual labor in loading and unloading, flipping, positioning, and stacking, enabling unmanned, continuous bending production.

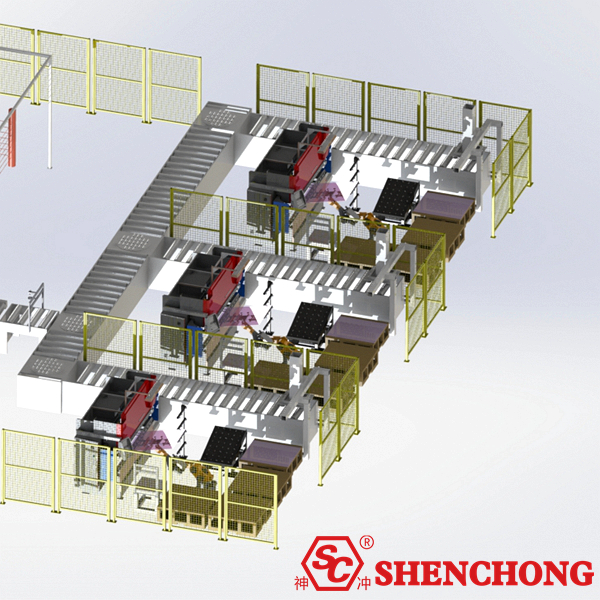

They are suitable for integration with intelligent material storage systems and laser cutting machines to form intelligent sheet metal production lines.

2) High Precision and Consistency

Workpiece gripping, handling, and bending positioning are all performed collaboratively by robots and CNC systems, eliminating human error.

Programmed operations ensure consistent bending angles and positions, making them particularly suitable for mass production.

3) Flexible Production

Robots can adapt to different workpieces by changing programs and fixtures, making them suitable for small-batch, high-variety sheet metal production.

They can be flexibly configured with different models of press brakes and auxiliary equipment.

4) Improved Production Efficiency

Robots operate quickly and continuously, requiring no rest, enabling 24-hour uninterrupted production.

Compared to manual operations, they offer more stable single-piece cycle times and significantly improved production efficiency.

5) Reduced Labor Intensity

Robots replace workers in handling heavy, large, or dangerous work pieces, improving the working environment and reducing occupational injuries.

Workers can now be transferred to technical positions such as programming and inspection.

6) High Safety

Robots assist in supporting and turning work pieces during the bending process, eliminating direct contact between workers and hazardous areas.

Integrated with safety light barriers and fencing, this creates a highly secure production cell.

7) High Scalability

Integrated with automatic loading and unloading systems, AGVs, high-bay warehouses, and laser cutting machines, creating a complete intelligent manufacturing production line.

Support for MES/ERP integration facilitates information management within smart factories.

Comparison table of robot bending cell vs manual bending:

Comparison Dimensions | Manual bending | Robot bending unit |

Production Efficiency | Unstable efficiency, dependent on worker skill and requiring rest breaks | Stable and efficient, capable of 24/7 continuous operation |

Bending Accuracy | Large variations due to operator influence | Program control ensures high angle consistency |

Adaptability | Small batches and a wide variety of products can be handled flexibly, but efficiency is low | Change programs and fixtures to achieve multi-variety production, providing greater flexibility |

Labor Intensity | High fatigue, especially with large and thick plates | Robots handle handling and flipping, significantly reducing worker workload |

Safety | Workers must be close to the bending danger zone, posing a safety hazard | Robots operate in hazardous areas, keeping personnel away from equipment, ensuring high safety |

Stability | High human influence, unstable production cycle | Stable and reliable, with a constant cycle time |

Labor Cost | Requires a large number of skilled workers, resulting in high training costs | High initial investment but long-term labor cost savings |

Scalability | Difficult to integrate with automated loading and unloading and warehousing systems | Can be integrated with laser cutting, material storage, AGVs, and other systems to create intelligent production lines |

Application Scenarios | Small-scale, high-volume production | Enables medium- and large-volume, standardized, and intelligent production |

4. Summary

A robot bending cell typically consists of a CNC press brake, an industrial robot, a fixture, a loading and unloading system, a control system, and safety features. Vision systems, tracking devices, and intelligent storage can be expanded to meet production needs, creating a flexible and intelligent sheet metal bending automated production line.

The complete workflow of a robotic bending cell is:

Loading → Positioning and Calibration → Bending → Flipping/Secondary Bending → Finished Product Unloading/Stacking → Quality Inspection (optional).

The entire process is coordinated by the robot, press brake, and CNC system, enabling unmanned, flexible, stable, and efficient sheet metal bending production.

The greatest value of a robot bending cell lies in improving efficiency, ensuring consistency, and reducing manual labor. While balancing flexible production with intelligent upgrades, it is ideal for sheet metal manufacturers transitioning from traditional manual operations to intelligent manufacturing.