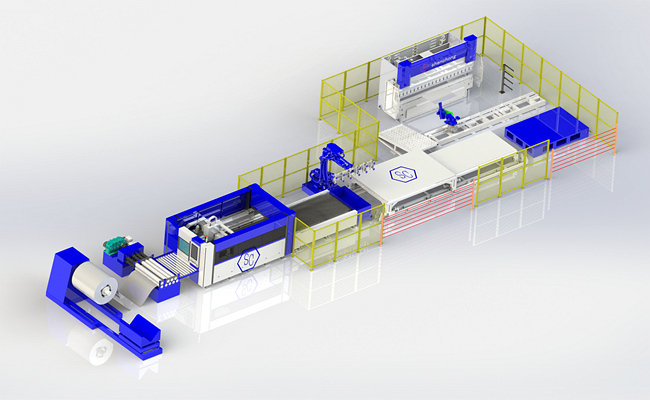

Metal Curtain Walls Processing Solution

Metal curtain walls, as a type of wall decoration applied to large buildings, are increasingly favored by the construction industry due to their excellent strength, flexible processing performance, and safety. Among them, aluminum panel curtain walls are the most widely used in metal curtain walls. Lightweight, can effectively reduce the load on buildings, has good rigidity and high flatness, providing good selection conditions for high-rise buildings.

Many customer ask: I want to produce the decorative customized aluminum facade cladding panel, interior metal cladding wall panel. Perforated corrugated metal panels,metal wall cladding, if you want to invest this project , SC SHENCHONG can supply complete solution line machines.

- Uncoiling and leveling machine

- CNC Fiber Laser Machine

- CNC Turret Punching Machine

- CNC V Grooving Machine(V Cut Machine)

- CNC Press Brake

- Fiber Laser Welding Machine

Pain Point

The commonly used aluminum plate cutting processes include CNC shearing machines, punching machines, and engraving machines. The equipment has significant limitations, with burrs on the cross-section and easy cracking when bent. During the production process, engraving machines are unable to process special shapes such as sharp and square corners, while punching machines are unable to solve the punching of irregular plates and have low efficiency. The rapid development of China’s economy has led to a surge in demand for metal curtain walls due to a large number of urban construction, airports, high-speed rail stations, and subway station projects. Many metal building materials processors are upgrading and expanding their technology. In order to gain a competitive advantage, shorten the manufacturing cycle, and improve product quality, efficient, high-quality, and automatic cutting and bending technology are considered simultaneously during technological upgrades.

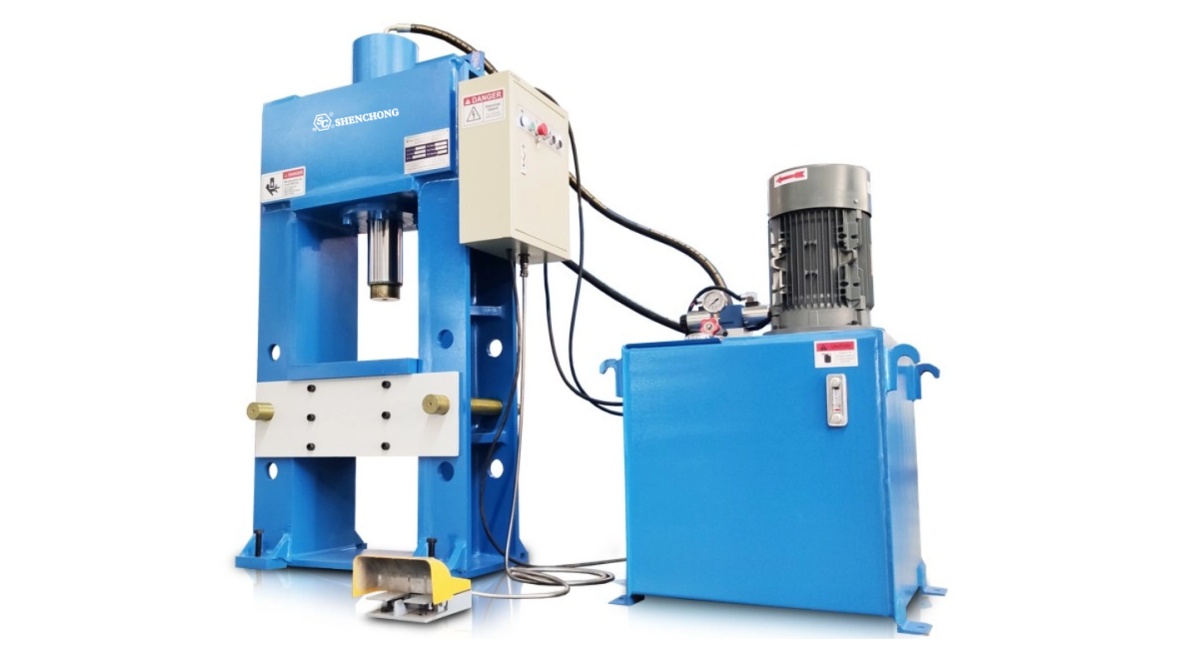

Solutions:

Aluminum Plate Flattening And Leveling Shear Line

Meets high flatness requirements, with a width of up to 2300mm, and multiple sets of support rollers are electrically adjusted.

Laser cutting can meet the requirements of small and medium-sized batch production without the need for mold opening, which is beneficial for new product development. Flexible processing and the ability to adjust production at any time according to the situation. Automatic layout, nesting and other processes improve the utilization rate of sheet metal. Completing machining projects such as holes and grooves before bending greatly improves production efficiency.

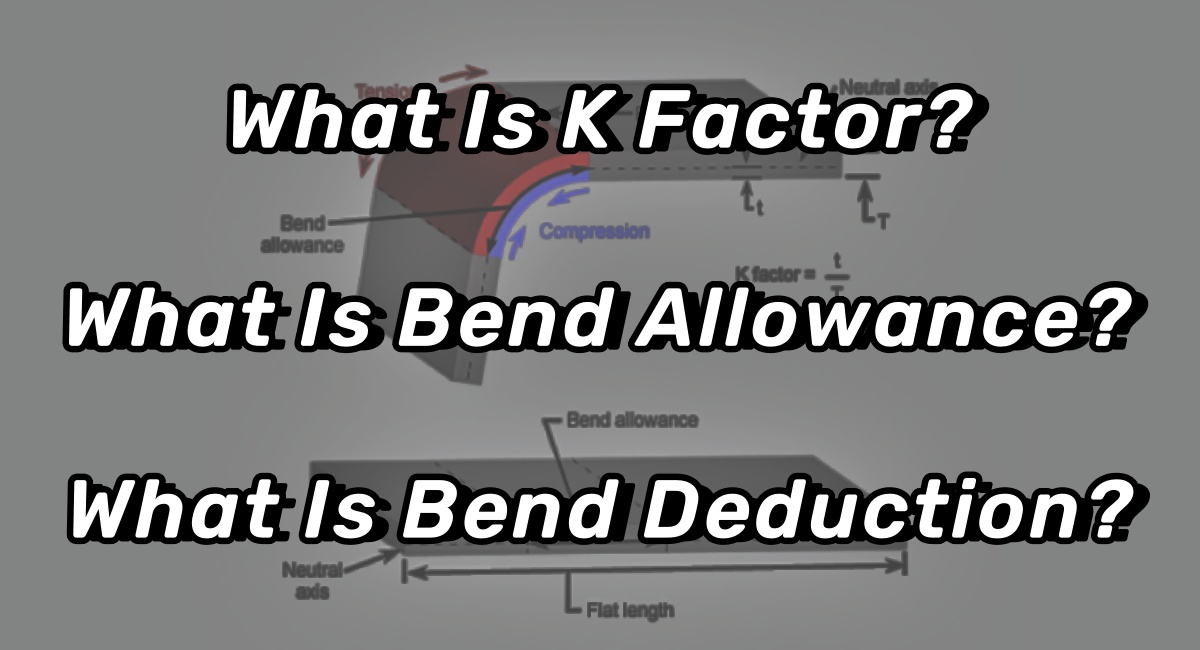

CNC V Grooving Machine

The first principle of aluminum veneer in curtain wall bending treatment is: the first folding does not interfere with the next cutting, and the second folding interferes. A typical bending machine can handle most of the bending requirements of curtain wall aluminum veneer, but for some more complex or several bends that are too close to each other, a CNC slotting machine needs to be used to slot some bends and then fold them to the desired angle.

Robotic CNC Press Brake

Since process the metal curtain usually bend the plate length from 2500mm to 4000mm, robotic cnc press brake machine is an ideal bending solution to reduce the labor cost and improve the productivity.