Table of Contents

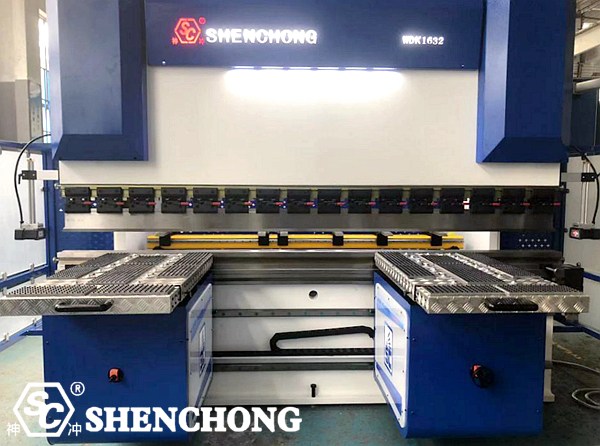

New Zealand hybrid servo press brake WDK-160T/3200 4+1+2 axis (with ESA S640 controller, laser protection and sheet follower device) is a high-end precision bending equipment, suitable for sheet metal processing companies with high requirements for efficiency, precision and safety.

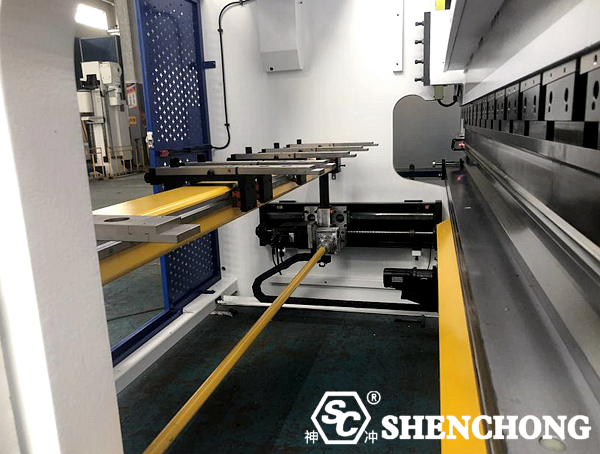

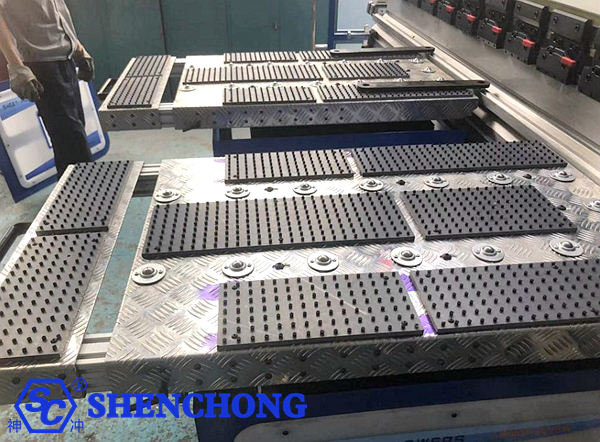

The hydraulic system of the hybrid servo press brake uses a servo motor to drive the pump, which is more energy-efficient and responsive than traditional hydraulics. It is equipped with two follow-up devices to facilitate the bending of large-format thin plates and effectively support and assist operations.

1. Configuration of New Zealand Hybrid Servo Press Brake Machine

- Pressure tonnage: 160 tons

- Bending length: 3200 mm

- Axis configuration: 4+1+2 axes

- Control system: ESA S640 controller (Italian brand, commonly used for high-end bending control)

- Safety device: equipped with MSD laser protection system

- Others: two bending follower devices (automatic accessories to support the bending of long plates)

2. Advantages of New Zealand Hybrid Bending Machine

- High efficiency and energy saving, suitable for mid-to-high-end sheet metal processing

- High precision, good laser protection safety

- Support multi-axis control, suitable for complex parts

- ESA controller has a user-friendly interface and powerful functions

Advantages analysis table:

Item | Advantages |

Precision | Multi-axis servo control + ESA automatic compensation, high bending precision |

efficient | Graphical programming + oil-electric hybrid drive |

Energy conservation | Only consumes electricity when working, reducing energy consumption |

Safety | Laser protection + CE certification |

Universality | Adapt to various molds and adapt to bending tasks in multiple industries |

Extensibility | Support intelligent transformation such as robot interface and network connection |

Hybrid drive system:

- Use servo motor + variable pump to drive the hydraulic system, which is different from traditional hydraulic presses: 30-50% energy saving.

- Fast response, shortened bending cycle.

- Low noise, suitable for workshops with high environmental protection requirements.

MSD laser protection device:

- Laser detection of mold area to prevent fingers or objects from entering.

- Meet international safety standards such as EU CE.

- Automatic avoidance/restricted area setting to ensure safe operation.

3. Main uses (industries and part types)

Applicable industries:

- Sheet metal processing plants

- Electric cabinets and distribution boxes manufacturing

- Kitchenware and home appliance housing manufacturing

- Elevators, doors and windows, air conditioning equipment

- Automotive parts and engineering machinery housings

- Stainless steel decoration projects (such as elevator decoration, billboards)

Typical workpiece types:

- Carbon steel, stainless steel, and aluminum plates as thin as 0.5 mm and as thick as 6 mm

- Large-size plates (supported by follower devices)

- Complex parts with multiple bending processes

- Workpieces with high consistency and batch requirements

If you have specific processing requirements (such as plate thickness range, annual output, whether automation is required, etc.), we can further match the most suitable machine model and configuration solution for you!