Table of Contents

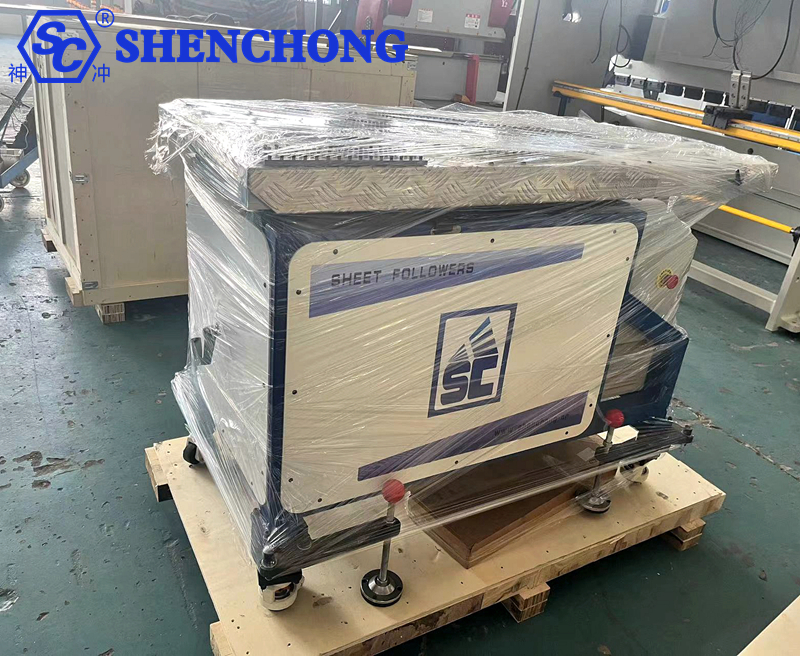

SC 200kg bending follower DLSD20 is an auxiliary device that supports and follows the sheet metal during the bending process, solving problems such as sagging, scratching, and excessive manual support during bending of large and thick plates. The 200kg series is suitable for single- or multi-person bending of medium and thick plates or large parts.

1. SC 200KG Bending Follower DLSD20 Technical Specifications

Parameter Table:

Name | Value | Unit |

Maximum Thrust | 200 | Kg*m |

Workbench Length | 1200-1600 | mm |

Workbench Width | 650 | mm |

Workbench Height | 950-1200 | mm |

Flip Angle Range | 0-75° | mm |

Maximum Tilting Speed | 40 | deg/s |

Motor Power | 3 | kw |

Loading Weight | 200 | Kg |

2. Main configuration Of SC 200KG Bending Follower For Sale

Configuration Table:

Name | Manufacturer |

Touch screen | Delta (Taiwan) |

AC contactor, thermal relay | Schneider (France) |

Circuit breaker, push button | Schneider (France) |

Micro relay | Schneider (France) |

PLC | Delta (Taiwan) |

Magnetic scale (accuracy 0.005mm) | ELGO (Germany) |

Servo motor | Delta (Taiwan) |

3. Recommended Working Conditions for 200kg Follow-Up Press Brakes

- Machine Tonnage: 160–200 ton(commonly used with 3200–4000mm models)

- Plate Thickness Reference (for follow-up load reference only. Actual machine selection should be based on bending force):

- Ordinary steel Q235: 2–8 mm thick plates are commonly used for 3–4 m plates.

- Stainless steel: 2–6 mm thick plates are commonly used for 3–4 m plates.

- Cycle Speed: It is recommended to be linked to the machine’s bending speed curve to avoid bumping/dragging.

- Surface Requirements: Brush, soft roller, or low vacuum suction.

Typical Applications for 200kg Sheet Follower Press Brakes:

- 3–4 m thick ordinary carbon steel, 3–8 mm thick; stainless steel, 2–6 mm thick; aluminum, 4–10 mm thick (depending on density/size).

- Large-sized panels, box side panels, door panels, cabinet side panels, engineering machinery covers, etc.

4. Key Parameters For Press Brake Bending Follower Selection

- Maximum panel size (length × width × thickness) and material, unit weight

- Pressbrake model (brand/tonnage/length/opening/throat depth/back gauge stroke/speed/control system)

- Bending process and angle range, required press brake trajectory

- Target cycle time (seconds/piece) and shift output

- Surface quality requirements (mirror finish/laminated/scratch-resistant)

- Interface type (I/O or bus) and site electrical standards

- Power/air source (e.g., AC380V, ≥0.6 MPa), environment (dust/oil mist)

- Site plan/photo (infeed/outfeed direction, obstructions).

Independent SC 200kg bending follower is designed to lift and synchronize large/heavy panels during the bending process, reducing sagging, scratching, and manual workload, achieving a more efficient and stable yield. The 200 kg rated load is compatible with common press brakes with a capacity of 160–250 tons and a width of 3200–4000 mm.