Table of Contents

SC EL CNC system EL15T, EL17T, EL19T, and EL21T CNC systems are SHENCHONG self-developed press brake operating systems. Designed specifically for CNC press brakes, they balance user-friendliness and high performance, making them suitable for high-precision, multi-step automated bending operations.

1. Introduction to SC EL CNC system for press brakes

- Name: SC EL CNC System

- Developer: Shenchong (SC)

- Applicable Equipment: CNC press brakes, such as electro-hydraulic synchronous CNC press brakes and hybrid servo CNC press brakes

- Type: Industrial-grade press brake control system

- Positioning: High performance, autonomous control, multi-language friendly, simple and intuitive human-machine interface

2. Key Features and Advantages

- Multi-axis control support

- Standard support for Y1, Y2, X, and R + V (pressure compensation) axes

- Extendable to special axis control such as Z1/Z2 and X’

- Supports complex profiles and multi-angle bending

- Intelligent Graphical Programming

- Equipped with a graphical programming interface

- Operators can directly create 2D graphics using the touchscreen

- The system automatically generates the process sequence and bending program

- Parametric Management

- Database management of parameters such as material, mold, bend angle, and springback

- Supports advanced features such as bend compensation and mold interference detection

- Touchscreen Design

- Utilizes a large, industrial-grade touchscreen LCD

- Smooth touch response, simple interface, and easy operation

- Multi-language support (including English, Russian, Thai, Vietnamese, Korean, Spanish, Chinese, Arabic, Polish, Greek, Indonesian, etc.)

- Automatic diagnosis and remote service

- Built-in fault diagnosis module

- Supports remote maintenance and program updates

3. Comparison of Different Series of SC EL CNC Systems

1) SC EL CNC system EL15T

SC EL15T CNC system is the most cost-effective press brake system and the standard configuration for Shenchong CNC press brakes. Based on different display styles, it is divided into the EL15T-A, EL15T-E, and EL15T-K.

EL15T-A:

- 15.6″ LED true-color LCD

- Linux operating system, stable and reliable

- Fast startup, with instant power-off functionality

- Quad-core processor, 1GHz operating frequency

- 256MB RAM, 4GB storage

EL15T-E:

- Optional resistive or capacitive touchscreen

- Programming options include data or 2D graphics

- Supports flattening and large arc dies

- Stores up to 9,999 dies

- 100M Ethernet port*1

EL15T-K:

- Automatic calculation of bending process and opening height

- Deflection compensation selectable in hydraulic or mechanical mode

- Calculation of unfolded length, X and R axis positions

- Automatic calculation of bending pressure and proportional control

- Standard 4+1 axis configuration

In addition to the cost-effective standard EL15T CNC system, we also offer the higher-end EL17T, EL19T, and EL21T systems. These systems can meet the needs of multi-axis CNC (6+1 and 8+1 axes), 3D programming, dual-machine linkage (tandem press brake), robotic press brake bending, and automated production lines.

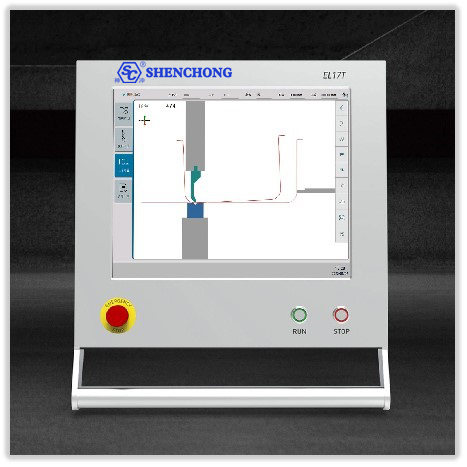

2) EL17T

- Same functions as the Delem DA68T

- 17-inch TFT true-color LCD

- Industrial-grade infrared touchscreen

- Linux operating system, stable and reliable

- Quad-core processor, 1GHz

- 1GB RAM, 8GB storage

- Optional SD card, up to 16GB

- Gigabit Ethernet port*1

- Programming options: data or 2D graphics

- Supports flattening and large arc dies

- Stores up to 9,999 dies

- Automatic calculation of bending steps and opening height

- Deflection compensation options: hydraulic or mechanical

- Calculation of unfolded length, X and R axis position

- Automatic calculation of bending pressure, proportional control

- Standard 4+1 axis configuration, optional 6+1 axis configuration

3) EL19T

- 18.5-inch capacitive touchscreen, multi-touch support

- Linux operating system, stable and reliable

- Quad-core processor, 1.8GHz

- 2GB RAM, 16GB storage Gigabit Ethernet port*1

- Standard 4+1 axis configuration, optional 6+1 and 8+1 axis configurations

- Various programming options available: data, 2D graphics, and single-track bend debugging

- Supports 3D simulation of machine tools and graphic products

- Supports multiple V-groove lower dies

- Supports product information entry via barcode scanner

- Supports product creation via DXF drawing import

- Supports hybrid servo electric press brakes

- Optional robot interaction and dual-machine linkage

- Optional multi-unit follow-up support

- Compatible with automated production lines

4) EL21T

- 21.5-inch capacitive touchscreen with multi-touch support

- Windows operating system, strong compatibility

- Intel i3/i5/i7 processor, up to 4.5GHz clock speed

- 8GB RAM, 128GB storage

- Automatic calculation of bending process and opening height

- Standard 4+1 axis configuration, optional 6+1 and 8+1 axis configurations, supporting up to 12+1 axis configurations

- Standard multi-V-gap lower die configuration, optional automatic V-gap switching

- Supports hybrid or pure electric press brakes

- Supports product information entry via barcode scanner

- Supports 3D simulation of machine tools and graphic products

- Various programming options available: data, 2D/3D graphics, and single-bend debugging

- Supports 2D drawing import in formats including DXF/DWG

- Optional 3D drawing import in formats including IGS/STEP/SLDPRT

- Optional multi-unit follow-up support

- Optional robot interaction and multi-machine linkage

- Can be integrated into automated production lines and MES management systems

SC EL CNC system comparison table:

EL15T | EL19T | EL21T | |

Configuration | — | — | — |

4+1 axes | ● | ● | ● |

6+1 axes | ○ | ○ | ○ |

8+1 axes | — | ○ | ○ |

Extended axes | — | ○ | ○ |

Dual-machine linkage | ○ | ○ | ○ |

Triple-machine linkage | — | ○ | ○ |

Multi-unit follow-up support | — | ○ | ○ |

2D programming, 2D simulation | ● | ● | ● |

2D programming, 3D simulation | — | ● | ● |

3D programming, 3D simulation | — | — | ● |

2D drawing import, DXF format | — | ○ | ● |

3D drawing import, IGS/STEP/SLDPRT format |

|

| ● |

Barcode scanner | — | ○ | ○ |

Pump control model | ● | ● | ● |

Electric motor model | ● | ● | ● |

Manipulator connection supported | ● | ● | ● |

Automated production line integration | — | ○ | ○ |

MES | — | ● | ● |

–: Not available | |||

○: Optional configuration | |||

●: Standard configuration | |||

SC EL CNC system is a system independently developed by Shenchong based on its bending manufacturing experience and CNC technology. It has powerful automatic programming capabilities, a clear human-machine interface, flexible axis control and good scalability. It performs well in actual sheet metal processing and is especially suitable for occasions with a high degree of automation, fast batch changes and high precision requirements.