Table of Contents

Sheet metal automatic loading and unloading refers to a technology and process that uses automated equipment to automatically transport, load and unload sheet metal plates or workpieces during sheet metal processing and production, thereby reducing manual intervention and improving production efficiency and processing quality.

Sheet metal automatic loading and unloading systems play an increasingly important role in modern sheet metal manufacturing, especially in laser cutting, stamping, bending, welding and other links, which can greatly improve efficiency, reduce labor costs, and improve product consistency and intelligence.

1. What is automatic loading and unloading of sheet metal?

Automatic loading and unloading of sheet metal refers to the process of automatically feeding sheets or workpieces into processing equipment (such as laser cutting machines, punching machines, bending machines, etc.) for processing during sheet metal processing, and automatically removing them from the equipment after processing. This system greatly reduces manual intervention and realizes the automation and efficient operation of the processing process.

Core content:

- Automatic loading: Automatically take out raw material sheets from the material warehouse or material rack and accurately place them on the workbench of processing equipment (such as laser cutting machines, punching machines, bending machines, etc.).

- Automatic unloading: Automatically remove the processed parts or finished products from the processing equipment and send them to the designated collection area or the next process.

- Intelligent control: Use PLC, robots, multi-sensors, etc. to realize the automation and intelligence of the entire loading and unloading process.

Main advantages:

- Save labor costs and reduce labor intensity.

- Improve processing efficiency and shorten production cycle.

- Improve processing accuracy and product consistency.

- Enhance production safety and reduce the risk of work-related injuries.

- Promote the digitalization and intelligent development of sheet metal manufacturing.

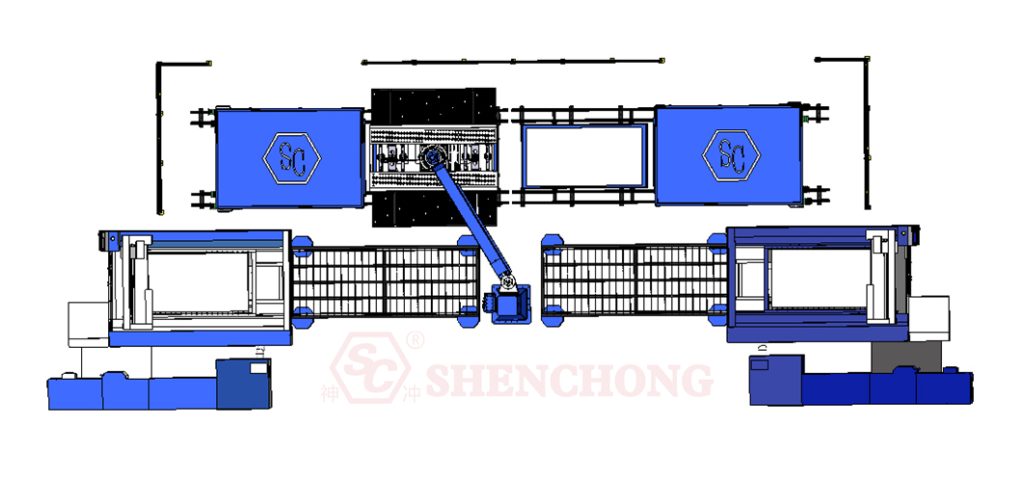

2. Composition of the sheet metal automatic loading and unloading system

The sheet metal automatic loading and unloading system is an important part of modern sheet metal processing automation. It mainly realizes the automatic handling, positioning and loading and unloading of sheets, improves processing efficiency, reduces labor costs, and improves product consistency. The following is a detailed analysis of the system:

1) Loading part (loading device)

Responsible for automatically delivering raw materials (sheets) from the storage area to the processing equipment workbench.

Main components:

- Loading rack/material warehouse

Stores multiple original sheets, and the structure can be stacked, drawer-type or material tower.

- Suction cup material picking system

The vacuum suction cup sucks the sheet out of the rack through the lifting arm to avoid scratching the surface.

Advantages: No contact damage, suitable for precision materials such as stainless steel.

- Lifting platform

Automatically adjusts the height to ensure that one sheet is sucked each time.

- Guide positioning device

Ensures the alignment accuracy of the sheet before it is placed on the processing equipment.

2) Conveying system (handling mechanism)

Realize the transfer of plates from the loading point to the processing table, or from the processing table to the unloading area.

Common types:

- Robot arm (multi-axis robot)

Equipped with suction cups or grippers, it performs loading and unloading and handling actions, and supports multi-angle precise positioning.

- Slide rail transverse mechanism/belt conveyor line

Applicable to moving plates from the loading area to the cutting platform, etc.

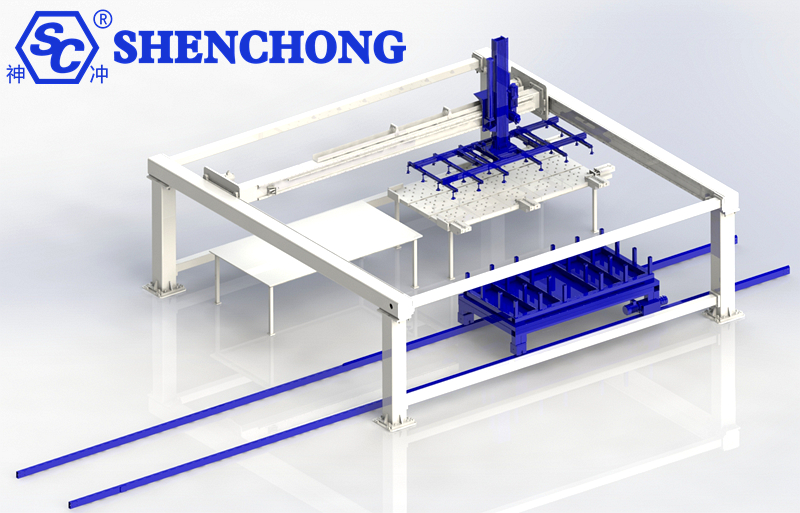

- Gantry-type grabbing system

Strong structural rigidity, suitable for high-frequency loading and unloading of large-size plates.

3) Unloading part (finished product/residual material processing system)

Responsible for sorting and transferring processed workpieces or residual materials from the processing platform to the designated location.

Core structure:

- Finished product grabbing mechanism

Can automatically identify the workpieces that have been cut, grab and transfer them.

- Residual material separation mechanism

Separates waste materials from finished products for subsequent processing and recycling.

- Sorting device

Classifies different types of workpieces according to size, shape or process.

- Discharging conveyor belt

Sends finished products or residual materials to the temporary storage area or the next process.

4) Control system (electronic control and information part)

Includes:

- PLC/industrial computer control system

Controls the action process, beat and safety interlock of each component.

- Human-machine interface (HMI)

Operators can set programs, monitor status, and process alarm information.

- Sensor system

Includes visual sensors, laser locators, pressure sensors, etc., used to identify information such as position, shape, thickness, etc.

- Communication interface with host equipment

Links with laser cutting machines, punching machines, bending machines and other equipment to ensure synchronous operation.

5) Safety protection system

- Photoelectric safety protection device

- Anti-collision sensor

- Emergency stop system

- Safety fence and access control

3. Common application equipment

Sheet metal automatic loading and unloading systems are widely used in a variety of sheet metal processing equipment to improve production efficiency, reduce manual participation, and achieve automated and intelligent production.

The following are several common sheet metal automatic loading and unloading system application equipment:

- Laser cutting machine automatic loading and unloading system

- CNC punching machine automatic loading and unloading system

- Press brake machine automatic loading and unloading system (with robot or follower device)

- Loading and unloading robot for welding or spraying line

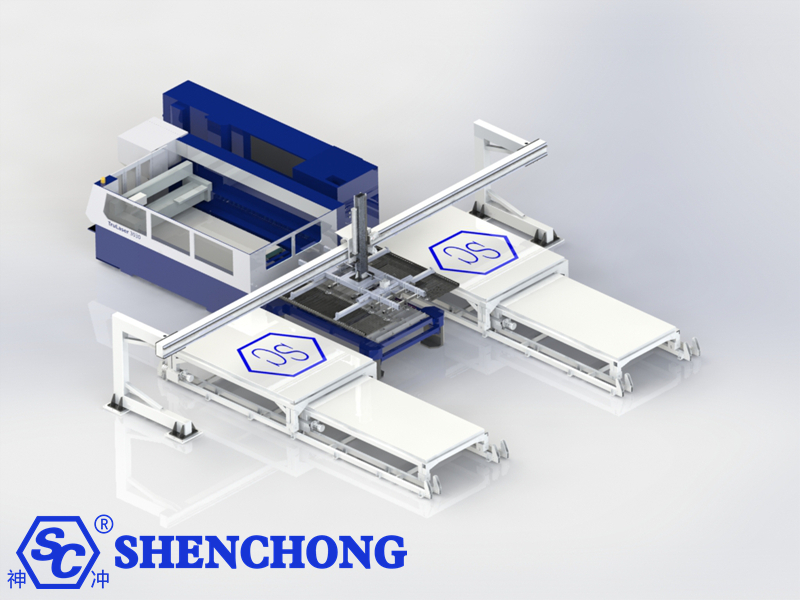

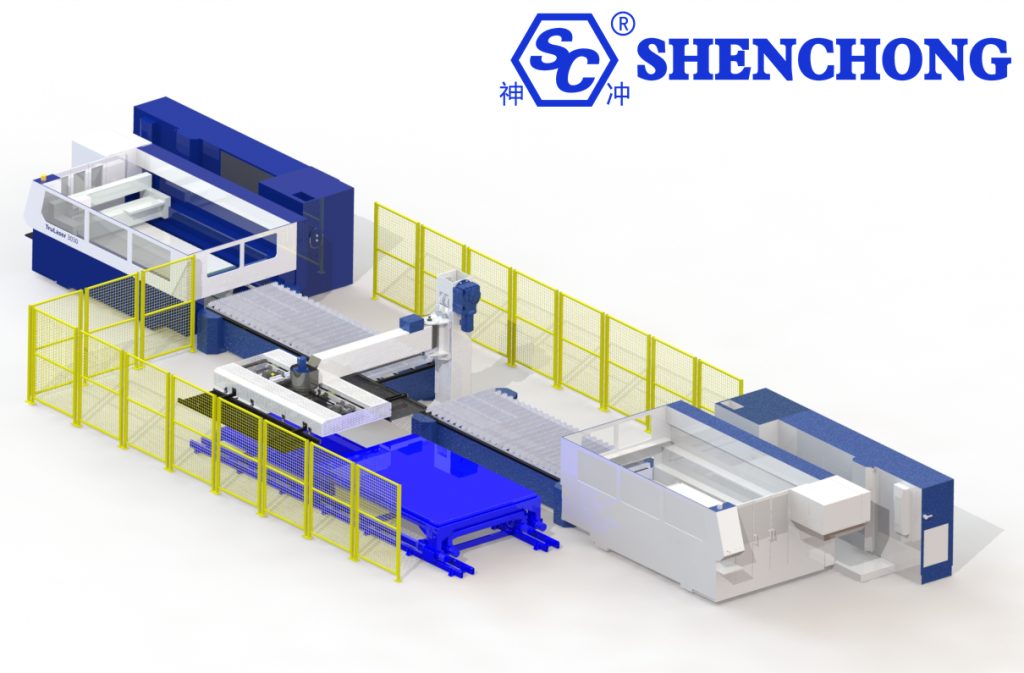

1) Automatic loading and unloading system for laser cutting machine

Application features:

- Automatic loading and positioning of the whole sheet, automatic unloading of finished products and residual materials after cutting.

- Applicable to medium and thick plates and large-scale processing scenarios.

Configuration structure:

- Vacuum suction cup loading arm

- Automatic lifting material warehouse or plate material tower

- Automatic sorting system after cutting (separation of finished products and edge materials)

- Equipped with visual recognition or plate recognition sensor

Representative applications:

- Fiber laser cutting machine

- CO₂ laser cutting equipment

2) Automatic loading and unloading system for CNC punching machine

Application features:

- Automatic feeding of the plate, automatic material removal after punching, and improving the efficiency of the entire line.

- Commonly used in plate punching, flanging, shallow drawing and other processes.

Configuration structure:

- Automatic plate stacking and loading arm

- Automatic feeding device

- Parts picking system and sorting platform

Integration method:

- Single automatic loading and unloading or inline FMS flexible production line

3) Automatic loading and unloading system of CNC bending machine

Application features:

- Automatically grab the plate to be bent, and perform automatic bending and stacking in multiple processes.

- Can be integrated with robots and follow-up devices.

Configuration structure:

- Six-axis or seven-axis bending robot

- Vacuum suction cup or clamping mechanism

- Automatic flipping, rotation positioning unit

- Automatic stacking device for finished products

Applicable scenarios:

- Cabinet manufacturing, sheet metal shell bending, parts with high precision requirements for multiple folding edges

4) Automatic loading and unloading system of shearing machine

Application features:

- Automatic feeding and positioning after shearing, automatic collection or transmission of sheared plates

Configuration structure:

- Loading rack or servo front feeding platform

- Feeding pusher/suction cup clamping mechanism

- Discharging conveyor line or sorting tray

5) Sheet metal welding or grinding robot loading and unloading system

Application features:

- For welding, grinding and other processes, use robots to automatically transport or position workpieces to improve consistency.

Configuration structure:

- Welding/grinding workstation

- Workpiece turntable or double-station platform

- Loading and unloading robot + identification system

6) Flexible manufacturing system (FMS) and sheet metal loading and unloading integration

Application features:

- Integrate multiple devices (laser/punch/bending) and logistics systems to realize “dark factory”.

- Achieve high automation and digital control.

Configuration structure:

- Automatic plate material warehouse + intelligent lifting system

- AGV or rail trolley conveying system

- MES system dispatches loading and unloading process

7) Other application scenarios of automatic loading and unloading equipment

- Automatic film loading and unloading machine: apply protective film before laser cutting, and complete the loading and unloading process

- Automatic loading and unloading of sheet metal coils: used to unwind from coils and feed into stamping/cutting equipment

- Automatic packaging line: finished plates enter the automatic packaging or intelligent storage system after loading and unloading

4. Schematic diagram of workflow (take laser cutting as an example)

The following takes the sheet metal laser cutting automatic loading and unloading system as an example to analyze its typical workflow in detail:

The entire process is divided into five steps: automatic loading → sheet positioning → laser cutting → automatic unloading → finished product sorting and stacking.

1) Automatic loading

Function:

Automatically transport the original sheet from the rack to the working platform of the laser cutting machine.

Main process:

The loading arm or suction cup grabs the sheet → the lifting platform adjusts the height → detects whether the adsorption is successful (avoid multiple absorption) → transports to the cutting platform and completes the placement.

Supporting equipment:

- Vacuum suction cup manipulator/adsorption arm

- Automatic lifting material warehouse/stacking rack

- Sheet thickness/sheet number detection sensor

2) Sheet positioning and detection

Function:

Ensure that the sheet is placed accurately and accurately on the cutting table.

Main process:

Photoelectric/laser sensor detects the position of the sheet →Automatically adjusts the X/Y direction →The system determines whether it meets the cutting requirements →Sends a “cutting preparation completed” signal to the laser cutting system.

Supporting equipment:

- Laser alignment sensor

- Precision limit device

- Automatic correction function of control system

3) Laser cutting processing

Function:

The laser cutting machine executes the processing program to cut the pattern/hole position of the plate.

Main process:

The processing program starts →The laser head cuts according to the path →The cutting completion signal is fed back to the control system.

Supporting equipment:

- Fiber laser cutting machine (or CO₂ laser)

- Automatic focus laser head

- CNC system (can be linked with MES system)

4) Automatic unloading

Function:

Remove the finished product and residual material from the workbench after cutting.

Main process:

Unloading robot arm or slide rail gripper grabs the workpiece →Move the finished product or edge material according to the program →Put the finished product on the designated unloading platform or stacking area.

Supporting equipment:

- Suction cup/magnetic suction cup robot arm

- Sorting and pushing mechanism

- Slide conveying system

5) Finished product sorting and stacking

Function:

Automatically classify and neatly stack different parts to prepare for the next process.

Main process:

Automatically identify the shape/number of finished products → Stacking robot stacks according to the set path → Or transfer to the automated conveying line/AGV docking point.

Supporting equipment:

- Secondary positioning camera (visual recognition)

- Multi-layer stacking lifting platform

- Automatic labeling/scanning code traceability system

Summary of the process diagram

Automatic loading of raw board → Positioning detection → Automatic transport to cutting table → Laser cutting processing → Cutting completed → Finished product and residual material identification → Automatic unloading and transportation → Finished product sent to the next process or stacking area

Key features of the workflow

- Automation level: unmanned operation of the entire process (can achieve 24-hour “dark factory”).

- Positioning accuracy: automatic calibration system to ensure processing accuracy.

- Efficiency improvement: continuous processing of multiple sheets, automatic scheduling.

- Safety: human-machine isolation, grating protection, misoperation warning.

5. Optional configuration and expansion of automatic loading and unloading system

On the basis of standard configuration, sheet metal automatic loading and unloading system can also be equipped with various optional configurations and expansion upgrades according to different production requirements, equipment types, and automation levels to achieve higher efficiency, stronger flexibility, and deep integration with intelligent manufacturing systems. The following is a detailed description by functional module classification.

1) Plate management type expansion configuration

- Automatic material warehouse/material tower system: multi-layer stacking structure, automatic layer selection and material collection, suitable for multi-variety small batch or continuous large batch production.

- Sheet thickness detection system: automatic identification of sheet thickness to prevent multiple sheets or wrong materials from being sucked at one time.

- Sheet size/type recognition system (visual or barcode recognition): automatically confirms whether the current loading sheet matches the program to achieve foolproofing and error prevention.

- Sheet automatic film system: suitable for scenes with high requirements for surface protection such as stainless steel and aluminum plates.

2) Loading and unloading execution device expansion

- Multi-axis collaborative robot: replaces traditional robotic arms to achieve more complex path planning and multi-angle grasping.

- Workpiece automatic flipping device: used before and after bending or after welding, when the workpiece needs to be automatically operated on the front and back sides.

- Dual-station switching platform/buffer area: one station is for cutting, the other station is for loading and unloading, which improves the utilization rate of cutting equipment.

- Adjustable suction cup fixture (multi-size adaptation): to meet the needs of grabbing plates of different specifications and improve flexibility.

3) Identification and tracking configuration

- QR code/barcode scanning system: to identify the plate or workpiece ID, and realize automatic traceability and work order binding.

- RFID smart label system: cooperate with MES system to realize the whole process tracking of plates/parts from warehousing to shipment.

- Visual recognition system: realize functions such as workpiece positioning, sorting, and defect detection.

4) Informationization and system integration

- MES system docking interface: dock with the enterprise MES system to realize automatic synchronization of loading and unloading information flow, scheduling management, and production line monitoring.

- ERP/WMS system integration: realize automatic flow of inventory information and order information, and optimize warehousing and material distribution.

- Industrial Ethernet/OPC communication module: support fast and stable communication with host equipment or upper system.

5) Post-processing and handling extension

- Automatic stacking system: can automatically stack finished products according to the shape and size of parts to improve the neatness of the discharge.

- AGV handling docking interface: linked with the AGV automatic trolley to realize unmanned handling from the production line to the warehouse or the next process.

- Automatic waste collection system: automatically recycle cutting/stamping residual materials to improve the cleanliness and recycling efficiency of the site.

6) Safety and human-machine collaboration configuration

- Safety grating/lidar: realize regional intrusion detection and emergency shutdown protection.

- Flexible protective cover/protective door: prevent personnel from mistakenly entering the robot arm operation area and improve the safety level.

- Manual assisted operation mode of human-machine collaboration: supports manual intervention or assisted handling under special working conditions.

Combination suggestions (reference scenario):

Production demand | Recommended extended configuration |

Multi-variety mixed orders | Automatic material warehouse + visual recognition + MES system docking |

High-precision processing | Plate thickness detection + automatic film lamination + automatic workpiece flipping device |

Large batch 24-hour continuous production line | Automatic stacking + AGV handling + waste collection system |

Small batch multi-process flexible production | Multi-axis robot + fixture quick change system + ERP integration |

6. Advantages and value of automatic loading and unloading

The automatic loading and unloading system for sheet metal plays an increasingly important role in modern sheet metal manufacturing, especially in laser cutting, stamping, bending, welding and other links, which can greatly improve efficiency, reduce labor costs, and improve product consistency and intelligence level. The following is a detailed explanation of its main advantages and value:

1) Advantages of automatic loading and unloading of sheet metal

– Improve production efficiency

Automatic and continuous loading and unloading saves manual handling and alignment time.

It can achieve 24-hour non-stop operation, which is particularly suitable for matching with high-speed processing equipment such as laser cutting.

– Reduce labor costs

Replace repetitive and labor-intensive handling work.

Reduce dependence on manual operation, save the number of employees and labor costs.

– Improve processing accuracy and consistency

Automatic positioning and loading have high accuracy, avoiding manual placement errors.

Ensure quality consistency and standardization between product batches.

– Ensure operational safety

Isolate people and equipment, reduce manual contact with dangerous equipment such as lasers and stamping, and reduce the risk of work-related injuries.

Equipped with photoelectric/radar protection devices to effectively protect the production area.

– Improve equipment utilization

Avoid equipment idleness waiting for manual loading and unloading, and improve equipment startup rate.

Link with cutting/bending/punching machines to optimize rhythm connection.

– Adapt to flexible production

Can be connected with MES/ERP system to achieve flexible production scheduling of multiple varieties and small batches.

Automatically identify material number, thickness, and size to achieve mixed flow operation.

– Achieve the foundation of intelligent manufacturing

Lay the foundation for building a “dark factory” and realize unmanned factories or less-manned factories.

Support intelligent manufacturing needs such as data collection, traceability, and capacity analysis.

2) Core value of automatic sheet metal loading and unloading

- Economic benefits: reduce labor and management costs, increase production capacity, and shorten delivery cycle.

- Management benefits: process standardization, traceability, data visualization, conducive to management and decision-making.

- Quality benefits: stable quality, reduce human operation errors, and improve yield rate.

- Market competitiveness: meet the requirements of high-end customers for automation and delivery response speed, and enhance corporate image.

3) Application scenario value example table

Industry | Advantages |

Chassis and cabinet manufacturing | Large-volume and multi-batch production has a fast pace and is highly dependent on manual labor. Automation can significantly improve efficiency. |

Elevator manufacturing | The plates are heavy and large in size. Automatic loading and unloading solves the problem of manual handling and improves safety. |

Home appliance sheet metal | Multi-specification production has a fast pace. Automatic loading and unloading combined with the MES system realizes flexible scheduling. |

New energy vehicle sheet metal parts | High precision requirements for parts, automation ensures consistency and assembly quality. |

7. Summary

The sheet metal automatic loading and unloading system is an automated system that automatically feeds metal sheets or workpieces into sheet metal processing equipment for processing (loading), and automatically removes the workpieces (unloading) after processing. It is an important part of sheet metal intelligent manufacturing and is widely used in laser cutting, CNC punching machines, bending machines and other equipment.

Basic components of the system:

- Loading device: automatically grabs raw materials (such as sheets) and places them on the processing platform

- Unloading device: automatically removes, sorts or stacks the processed workpieces

- Handling mechanism: such as suction cup manipulators, robots, slide rail trolleys, etc.

- Control system: PLC, sensors, HMI, etc., to achieve intelligent control and linkage operation

Main advantages:

- Improve efficiency: achieve continuous production and reduce waiting time

- Reduce labor costs: reduce the need for operators

- Improve processing accuracy: accurate positioning to avoid human errors

- Enhance safety: reduce direct contact between humans and equipment

- Support intelligent manufacturing: can be connected to MES/ERP systems to achieve automation and information integration