Kitchen Industry Processing Background

Most kitchenware are made of stainless steel sheet metal panels with a thickness of 3mm or less, which are widely favored by the market for their corrosion resistance, aesthetics, and practicality. Kitchen products are also a part of furniture. Good kitchenware can add icing on the cake to the overall home environment, and objectively reflect people’s taste and habits in life. Good kitchen utensils can also make consumers use them comfortably and with peace of mind.

However, traditional sheet metal processing methods are cumbersome, time-consuming, and have high labor costs, which cannot meet market demands.

Pain Points:

However, traditional sheet metal processing methods are cumbersome, time-consuming, and have high labor costs, which cannot meet market demands.

Solution:

Nowadays, in addition to CNC punching machines, most of the kitchenware processing industry is based on laser cutting machines. For kitchenware manufacturers, the processing technology determines the quality of the kitchenware, and the quality determines the price and profit of the kitchenware. Therefore, in order to increase the profit, changing the processing technology is a good choice. As high efficiency intelligent machines for cutting and bending, the laser cutting machine, CNC press brake and automatic panel bender are the most suitable equipment for kitchenware processing.

Laser Cutting Machine

The emergence of laser cutting machines has revitalized the kitchen supplies manufacturing industry.

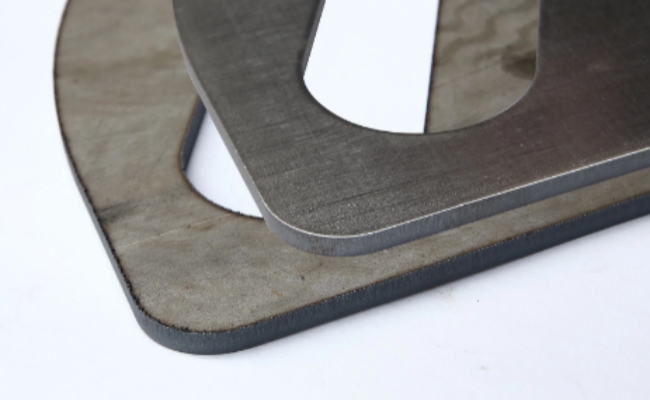

During the processing of kitchen utensils, cutting of stainless steel materials and pattern carving on metal surfaces can be completed through automatic programming of fiber laser cutting machines. Unlike traditional processing methods, laser cutting technology has advantages such as high cutting accuracy, fast cutting speed, smooth cutting end face, and no need for secondary processing.

Laser cutting machine does not require molds and cutting tools, simplifies the processing technology and process, has a short production cycle, and saves time and cost for enterprises in the mold opening process. In terms of labor costs, it will also greatly save. Previously, ten people could do the work, but now one person can operate the cutting. Laser cutting machines do not have stamping during processing, and the processed surface has no burrs, so there is no need for secondary processing. Prototyping can quickly achieve mass production.

Laser cutting technology meets the customization needs of the kitchen supplies market very well. It not only has fast processing speed, high efficiency, and simple operation, but also can complete various shapes of board cutting without the need for mold or tool replacement, shorter production cycle, no need for secondary processing, and can quickly achieve mass production, saving consumables and labor costs.

For intelligent manufacturing, we recommend SC1503FC Uncoiling and leveling laser cutting machine with automatic hydraulic uncoiling, leveling and feeding device, which helps to improve the production efficiency.

Panel Bender

Due to the large number of commercial kitchenware enterprises using thinner stainless steel plates (with a thickness of less than 0.8mm), during manual bending, the pursuit of efficiency and synchronization of operation by operators is difficult to achieve, making it inevitable to reverse bend. After using the panel bender, there is no need for manual lifting of the large panel during the bending process, avoiding the reverse bending caused by manual lifting not in place. The surface quality is greatly improved, and the production efficiency is also greatly improved compared to using a bending machine, with an average increase of more than 40%.

The automatic panel bender machine can meet the needs of small batch and multi variety production. The SC automatic panel bending center only takes a few seconds to complete the processing of folding the long edge first and then the short edge (short package length).

CNC Press Brake

The CNC press brake machine is widely used in the production of kitchenware, and can produce various types of kitchenware, such as pots, refrigerators, and stainless steel kitchen countertops etc.

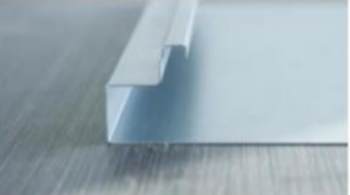

Metal Deburring Machine

For those kitchenware manufacturers who want to produce more beautiful products, we also recommend to use metal deburring machine after laser cutting, to reduce the cross section burrs.